About Composites

More

About Plastic

More

About Selecting Thermal Insulation

More

Slippery UHMW Polyethylene Sheets, Bars, and Strips

In addition to having a low-friction surface that prevents sticking and binding, this tough, impact- and wear-resistant material handles the scuffs, scrapes, and strikes that other plastics can’t. These sheets, bars, and strips are often used to make machine guards and chute liners. They are all FDA compliant for direct food contact.

- Temperature Range: -20° to 180° F

- Tensile Strength: 4,350-5,800 psi (Poor)

- Impact Strength: 16.8 ft.-lbs./in. (Excellent)

- Hardness: Durometer 65D-67D (Medium)

- For Use Outdoors: No

- Specifications Met: See Table

| Wd. | Lengths, ft. | Fabrication | Specifications Met | Per Ft. | |

White | |||||

|---|---|---|---|---|---|

5/16" Thick. (-0.03" to 0.03") | |||||

| 5/16" | Extruded | ASTM D4020 ASTM D6712 FDA Compliant 21 CFR 177.1520 UL 94 HB | 00000000 | 00000 | |

Black | |||||

5/16" Thick. (-0.03" to 0.03") | |||||

| 5/16" | Extruded | ASTM D4020 ASTM D6712 FDA Compliant 21 CFR 177.1520 FDA Compliant 21 CFR 178.2010 FDA Compliant 21 CFR 178.3297 UL 94 HB | 00000000 | 0000 | |

Wear-Resistant Easy-to-Machine Delrin® Acetal Resin Sheets, Bars, and Strips

These sheets, bars, and strips resist expanding when exposed to heat and moisture, so they can be easily machined to close tolerances. They also have a naturally slippery, wear-resistant surface. Use them to make precision gears, bushings, and bearings. Delrin® acetal resin, also known as acetal homopolymer, is stronger and stiffer than acetal copolymer.

White sheets, bars, and strips are FDA compliant for contact with food.

- Color: White or Black

- Temperature Range: -20° to 180° F

- Tensile Strength: 10,000-11,000 psi (Good)

- Impact Strength: 1-1.5 ft.-lbs./in. (Poor)

- Hardness: Rockwell R120-R122 (Hard)

- For Use Outdoors: No

- Specifications Met:

White: ASTM D6100, FDA Compliant 21 CFR 177.2480

Black: ASTM D6100

Wear-Resistant Nylon Sheets, Bars, and Strips

With a slippery surface that reduces friction, these wear-resistant nylon 6/6 sheets, bars, and strips are often machined into bearings, gears, and valve seats.

- Color: Off-White or Black

- Max. Temperature: 210° F

- Tensile Strength: 11,200-12,300 psi (Good)

- Impact Strength: 0.6-1.4 ft.-lbs./in. (Poor)

- Hardness: Rockwell R108-R121 (Hard)

- For Use Outdoors: No

- Specifications Met: See table

Chemical-Resistant Slippery Sheets and Bars Made from Teflon® PTFE

Made with Teflon® PTFE resins, these sheets and bars surpass most plastics when it comes to chemical resistance and performance in extreme temperatures. In addition to resisting most solvents, they are excellent electrical insulators. They're easy to machine and have a naturally slippery surface that makes them a good choice for bearings, gears, and parts that slide and roll.

- Color: White

- Temperature Range: -350° F to 500° F

- Tensile Strength: 2,170-2,800 psi (Poor)

- Impact Strength: 3.5 ft.-lbs./in. (Good)

- Hardness: Durometer 52D-55D (Medium Soft)

- For Use Outdoors: Yes

- Specifications Met: See Table

Multipurpose Flame-Retardant Garolite G-10/FR4 Sheets and Bars

A good all-around choice, these Garolite G-10/FR4 sheets and bars are strong, machinable, and electrically insulating. They're made of a flame-retardant epoxy resin with fiberglass fabric reinforcement. Garolite G-10/FR4 is also called epoxy-grade industrial laminate and phenolic.

If you don't see the size you're looking for, please specify a length under additional bar lengths.

- Color: See Table

- Max. Temperature: 280° F

- Tensile Strength: 35,000-50,000 psi (Excellent)

- Impact Strength: 5.5-12 ft.-lbs./in. (Excellent)

- Hardness: Rockwell M110 (Extra Hard)

- For Use Outdoors: No

- Specifications Met: MIL-I-24768/27, UL 94 V-0

Yellow sheets vary in shade from yellow-brown to light green.

| Thick. | Thick. Tolerance | Each | |

6" × 6" | |||

|---|---|---|---|

Black | |||

| 5/16" | -0.026" to 0.026" | 000000000 | 000000 |

Yellow | |||

| 5/16" | -0.026" to 0.026" | 00000000 | 00000 |

12" × 12" | |||

Black | |||

| 5/16" | -0.026" to 0.026" | 000000000 | 00000 |

Yellow | |||

| 5/16" | -0.026" to 0.026" | 00000000 | 00000 |

12" × 24" | |||

Yellow | |||

| 5/16" | -0.026" to 0.026" | 00000000 | 00000 |

24" × 24" | |||

Yellow | |||

| 5/16" | -0.026" to 0.026" | 00000000 | 000000 |

24" × 36" | |||

Yellow | |||

| 5/16" | -0.026" to 0.026" | 00000000 | 000000 |

36" × 48" | |||

Yellow | |||

| 5/16" | -0.026" to 0.026" | 00000000 | 000000 |

Economical Electrical-Insulating Garolite XX Sheets and Strips

Stronger than Garolite CE with better electrical-insulating properties, Garolite XX sheets and strips are often fabricated into low-cost electrical components. Garolite XX is constructed of a phenolic resin with paper reinforcement, which makes it easy to machine. It's also known as paper-grade industrial laminate, phenolic, and Bakelite.

- Color: Brown

- Max. Temperature: 265° F

- Tensile Strength: 8,000-23,900 psi (Excellent)

- Impact Strength: 0.35-0.55 ft.-lbs./in. (Poor)

- Hardness: Rockwell M100 (Extra Hard)

- For Use Outdoors: No

- Specifications Met: MIL-I-24768/11, UL 94 HB

High-Temperature Garolite G-11 Sheets and Bars

Offering higher strength and better heat resistance than Garolite G-10/FR4, these Garolite G-11 sheets and bars are suitable for continuous use in elevated temperatures. They retain at least 50% of their structural strength at temperatures above 300° F. Made of an epoxy resin with fiberglass fabric reinforcement, Garolite G-11 is sometimes called epoxy-grade industrial laminate and phenolic.

- Color: Green

- Max. Temperature: 335° F

- Tensile Strength: 37,000-58,600 psi (Excellent)

- Impact Strength: 7-15.3 ft.-lbs./in. (Excellent)

- Hardness: Rockwell M100 (Extra Hard)

- For Use Outdoors: No

- Specifications Met: MIL-I-24768/3, UL 94 HB

Flame-Retardant High-Temperature Garolite G-11/FR5 Sheets

- Color: Yellow

- Max. Temperature: 355° F

- Tensile Strength: 35,000 psi (Excellent)

- Impact Strength: 10 ft.-lbs./in. (Excellent)

- Hardness: Rockwell M115 (Extra Hard)

- For Use Outdoors: No

- Specifications Met: MIL-I-24768/28

Often used for terminal boards, electrical housings, end plates, and structural components in high temperatures, these sheets are a flame-retardant version of Garolite G-11. All are stronger and resist heat better than Garolite G-10/FR4. They keep at least 50% of their structural strength at temperatures above 300° F. These sheets are made of a flame-retardant epoxy resin that is reinforced with fiberglass fabric.

Garolite G-11/FR5 is also known as epoxy fiberglass, epoxy-grade industrial laminate, and phenolic.

Easy-to-Machine Garolite LE Sheets and Strips

- Color: Brown

- Max. Temperature: 235° F

- Tensile Strength: See Table

- Impact Strength: See Table

- Hardness: Rockwell M100 (Extra Hard)

- For Use Outdoors: No

- Specifications Met: See Table

Using nothing more than standard high-speed steel tooling, these Garolite LE sheets and strips can be machined into intricate parts. Garolite LE is made of a phenolic resin with a fine-weave linen fabric reinforcement. It is sometimes referred to as industrial laminate, phenolic, and Bakelite.

| Thick. | Thick. Tolerance | Impact Strength | Tensile Strength | Specifications Met | Each | |

6" × 6" | ||||||

|---|---|---|---|---|---|---|

| 5/16" | -0.015" to 0.029" | 1.11 ft.-lbs./in. | 9,300 psi | MIL-I-24768/13, UL 94 HB | 0000000 | 000000 |

12" × 12" | ||||||

| 5/16" | -0.015" to 0.029" | 1.11 ft.-lbs./in. | 9,300 psi | MIL-I-24768/15, UL 94 HB | 00000000 | 00000 |

12" × 24" | ||||||

| 5/16" | -0.015" to 0.029" | 1.11 ft.-lbs./in. | 9,300 psi | MIL-I-24768/15, UL 94 HB | 00000000 | 000000 |

24" × 24" | ||||||

| 5/16" | -0.015" to 0.029" | 1.11 ft.-lbs./in. | 9,300 psi | MIL-I-24768/15, UL 94 HB | 00000000 | 000000 |

24" × 36" | ||||||

| 5/16" | -0.015" to 0.029" | 1.11 ft.-lbs./in. | 9,300 psi | MIL-I-24768/15, UL 94 HB | 00000000 | 000000 |

36" × 48" | ||||||

| 5/16" | -0.015" to 0.029" | 0.8 ft.-lbs./in. | 11,700 psi | MIL-I-24768/13, UL 94 HB | 00000000 | 000000 |

Solderless Ready-to-Use Circuit Boards

Also known as solderless breadboards. A contact point inside each hole creates a connection without soldering. Use the terminal strips to connect your electronic components.

Boards with 170 contact points are often used for prototyping applications since they’re smaller. They’re available in a variety of colors to keep multiple prototyping projects organized.

Boards with 400, 830, or 2,390 contact points include distribution strips that ground connections and send power to your electronic components. Some also include connection posts, so you can connect to an external power supply. To organize your connections, choose a board with numbered and lettered holes.

Polyoxymethylene boards handle higher temperatures than ABS boards, which makes them good for burn-in testing.

Terminal Strips | Distribution Strips | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Total No. of Contact Points | No. of | No. of Contact Points | No. of | No. of Contact Points | Lg. | Wd. | Thick. | Hole Ctr.-to-Ctr. | Max. Temp., °F | Choose a Color | Each | |

ABS Plastic | ||||||||||||

| 170 | 2 | 85 | 0 | 0 | 1 7/8" | 1 7/16" | 5/16" | 0.1" | 155° | 00000000 | 00000 | |

Polyoxymethylene Plastic | ||||||||||||

| 400 | 1 | 300 | 2 | 50 | 3 5/16" | 2 1/8" | 5/16" | 0.1" | 300° | White | 0000000 | 0000 |

with Numbered

and Lettered Holes

Terminal Strips | Distribution Strips | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Total No. of Contact Points | No. of | No. of Contact Points | No. of | No. of Contact Points | Lg. | Wd. | Thick. | Hole Ctr.-to-Ctr. | Max. Temp., °F | Includes | Color | Each | |

ABS Plastic | |||||||||||||

| 400 | 1 | 300 | 2 | 50 | 3 5/16" | 2 1/8" | 5/16" | 0.1" | 180° | __ | White | 0000000 | 00000 |

| 830 | 1 | 630 | 2 | 100 | 2 1/8" | 6 1/2" | 5/16" | 0.1" | 180° | 70 Jumper Wires (22 Ga., 0.1" to 5" lg.) 3 Connection Posts 5 Antislip Feet | White | 0000000 | 00000 |

| 830 | 1 | 630 | 2 | 100 | 6 1/2" | 2 1/8" | 5/16" | 0.1" | 180° | __ | White | 0000000 | 0000 |

| 830 | 1 | 630 | 2 | 100 | 6 1/2" | 2 1/8" | 5/16" | 0.1" | 180° | 70 Jumper Wires (22 Ga., 0.1" to 5" lg.) | White | 0000000 | 00000 |

| 2,390 | 3 | 630 | 5 | 100 | 6 7/8" | 6 1/2" | 5/16" | 0.1" | 180° | 140 Jumper Wires (22 Ga., 0.1" to 5" lg.) 4 Connection Posts 5 Antislip Feet | White | 0000000 | 00000 |

Polyoxymethylene Plastic | |||||||||||||

| 830 | 1 | 630 | 2 | 100 | 6 1/2" | 2 1/8" | 5/16" | 0.1" | 300° | __ | White | 0000000 | 0000 |

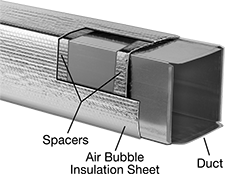

Heat-Reflecting Air Bubble Duct Insulation Sheets

- Temperature Range: -60° to 180° F

- Heat Flow Rate: Not Rated

- Density: Not Rated

- Color: Silver

- Specifications Met: ASTM E84 20/30 for Flame and Smoke

Typically used as duct wrap, these flexible sheets consist of polyethylene bubbles covered with aluminum polyester foil that prevent 96% of heat from radiating into or away from duct. Use on rectangular and round ductwork.

Spacers installed between the duct and air bubble insulation sheet increase the R-value to 6. One spacer roll covers approximately 10 ft. of 8" duct.

| Thick. | Wd. | Lg., ft. | Each | |

| 5/16" | 2" | 25 | 0000000 | 00000 |