Filter by

Mount Type

Thread Size

Head Diameter

Thread Depth

Diameter

Ball Material

Maximum Temperature

Minimum Temperature

Housing Material

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Weight Capacity

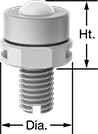

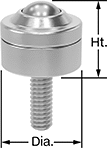

Threaded-Hole-Mount Ball Knobs

Thread | Head | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp. | Dia. | Ht. | Hub Ht. | Hub Dia. | Insert Material | Temp. Range, ° F | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

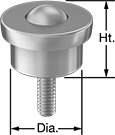

Style 1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 11/16" | — | — | — | Brass | -30 to 400 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 13/16" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 1 1/4" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 5/8" | 1 1/4" | — | — | — | — | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 7/16" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 1/4" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 7/16" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1/2" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1/2" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 1/4" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 7/16" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 1/2" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 5/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 2" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 1/4" | 1 15/16" | — | — | — | — | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1/2" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1/2" | 1 1/4" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 5/8" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 7/8" | 1 15/16" | — | — | — | Zinc-Plated Steel | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 7/8" | 2" | — | — | — | Zinc-Plated Steel | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-20 | 3/4" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 1 1/4" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 1 7/16" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3/4" | 2" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 7/8" | 1 3/8" | — | — | — | — | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 7/8" | 1 1/2" | — | — | — | — | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1" | 1 15/16" | — | — | — | — | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 5/8" | 1 1/4" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 5/8" | 1 3/8" | — | — | — | Zinc-Plated Steel | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 1 1/8" | 1 15/16" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 3/4" | 2" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 1 3/16" | 1 15/16" | — | — | — | — | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 × 0.7 mm | 10 mm | 17 mm | — | — | 10 mm | Brass | -20 to 380 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 12 mm | 32 mm | — | — | 13 mm | Brass | -20 to 380 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 12 mm | 35 mm | — | — | 16 mm | Brass | -20 to 380 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 25 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 12 mm | 38 mm | — | — | 16 mm | Brass | -20 to 380 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 25 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 35 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 25 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 35 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 18 mm | 35 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 18 mm | 49 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 21 mm | 49 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Red Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 11/16" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 11/16" | — | — | — | Brass | 0 to 300 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 7/16" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1/2" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1/2" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 5/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 1/4" | 1 15/16" | — | — | — | — | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 5/8" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 7/8" | 1 15/16" | — | — | — | Zinc-Plated Steel | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-20 | 3/4" | 1 3/8" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 7/8" | 1 3/8" | — | — | — | — | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1" | 1 15/16" | — | — | — | — | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 5/8" | 1 3/8" | — | — | — | Zinc-Plated Steel | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 1 1/8" | 1 15/16" | — | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 1 3/16" | 1 15/16" | — | — | — | — | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 25 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 25 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 35 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 25 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 35 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 18 mm | 35 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 18 mm | 49 mm | — | — | — | Brass | -30 to 400 | 00000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 21 mm | 49 mm | — | — | — | Brass | -30 to 400 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 3/8" | 3/4" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3/8" | 3/4" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3/8" | 1" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3/8" | 1 1/4" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 3/4" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 1/4" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 3/8" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 1/2" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 5/8" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 1/4" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 3/8" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 1/2" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 5/8" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 7/8" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 1/4" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 3/8" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 1/2" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 5/8" | — | — | — | Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 7/8" | — | — | — | Plain Brass | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 1 1/4" | — | — | — | Zinc-Plated Steel | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 1 3/8" | — | — | — | Zinc-Plated Steel | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 1 1/2" | — | — | — | Zinc-Plated Steel | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 1 7/8" | — | — | — | Zinc-Plated Steel | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 7/8" | 1 5/8" | — | — | — | Zinc-Plated Steel | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 7/8" | 1 7/8" | — | — | — | Zinc-Plated Steel | -15 to 225 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 32 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 35 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 38 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 41 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 13 mm | 48 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 32 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 35 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 38 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 41 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 13 mm | 48 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 32 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 35 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 38 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 41 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 48 mm | — | — | — | Plain Brass | -15 to 225 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Red Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 5/16" | 1 1/4" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 1/4" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 3/8" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 1/2" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 1/4" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 3/8" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 1/2" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 7/8" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 1/4" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 3/8" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 1/2" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 7/8" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1/2" | 1 1/4" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 1 3/8" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 1 1/2" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 5/8" | 1 7/8" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 7/8" | 1 7/8" | — | — | — | Brass | -15 to 125 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

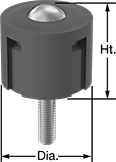

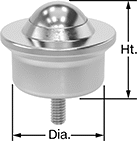

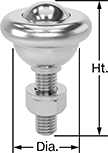

Style 2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 1 1/16" | — | 1/4" | 7/16" | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 1 1/4" | — | 5/16" | 1/2" | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Red Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 3/8" | 1 1/16" | — | 1/4" | 7/16" | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 1 1/4" | — | 1/16" | 1/2" | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 3/8" | 1 1/4" | — | 5/16" | 1/2" | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 1/4" | — | 1/16" | 1/2" | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

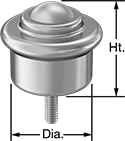

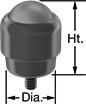

Style 3 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 2" | 1 9/16" | — | — | Brass | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 5/8" | 2" | 1 9/16" | — | — | Zinc-Plated Steel | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 1/16" | 2" | 1 9/16" | — | — | Zinc-Plated Steel | -30 to 400 | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

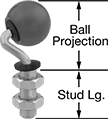

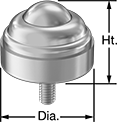

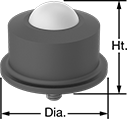

Stud-Mount Ball Transfers

|  |  |  |

Style A | Style B | Style C | Style D |

|  |  |  |

Style E | Style H | Style J | Style M |

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Ball Dia. | Wt. Cap., lb. | Ht. | Dia. | Working Orientation | Housing Color | Thread Size | Stud Lg. | Min. | Max. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M | 1" | 110 | 1 3/8" | 2 1/16" | Ball Up, Ball Down, Angled | Gray | 5/16"-18 | 5/8" | 32 | 104 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/8" | 125 | 13/16" | 15/16" | Ball Up, Ball Down, Angled | — | 1/4"-20 | 3/4" | 32 | 212 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1" | 200 | 1 1/4" | 1 3/8" | Ball Up, Ball Down, Angled | — | 5/16"-18 | 3/4" | 32 | 212 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/8" | 130 | 53/64" | 15/16" | Ball Up, Ball Down | — | 1/4"-20 | 3/4" | Not Rated | 225 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1" | 65 | 1 17/32" | 1 27/32" | Ball Up | — | 1/4"-20 | 7/8" | Not Rated | 225 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1" | 440 | 1 1/4" | 1 1/2" | Ball Up, Ball Down | — | 5/16"-18 | 3/4" | Not Rated | 225 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 1/2" | 250 | 2 5/16" | 2 3/16" | Ball Up, Ball Down | — | 3/8"-16 | 1" | Not Rated | 225 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 1/4"-20 | 11/16" | Not Rated | 225 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 5/16"-18 | 11/16" | Not Rated | 225 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 3/8"-16 | 11/16" | Not Rated | 225 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1/2" | 65 | 11/16" | 7/8" | Ball Up, Ball Down | — | 1/4"-20 | 3/4" | Not Rated | 225 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | 3/4" | 40 | 31/32" | 1 9/32" | Ball Up, Ball Down, Angled | — | M8 | 1 31/32" | -22 | 128 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | 1" | 55 | 1 9/32" | 1 9/16" | Ball Up, Ball Down, Angled | — | M8 | 1" | -22 | 128 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| J | 1" | 75 | 1 7/16" | 1" | Ball Up, Ball Down, Angled | — | 1/4"-20 | 7/16" | Not Rated | 225 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| J | 1" | 75 | 1 7/16" | 1 7/32" | Ball Up, Ball Down | — | 5/16"-18 | 11/16" | Not Rated | 225 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| J | 1 1/4" | 250 | 1 3/4" | 1 1/4" | Ball Up, Ball Down, Angled | — | 3/8"-16 | 15/16" | Not Rated | 225 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/8" | 130 | 53/64" | 15/16" | Ball Up, Ball Down | — | 1/4"-20 | 3/4" | Not Rated | 400 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1" | 65 | 1 17/32" | 1 27/32" | Ball Up | — | 1/4"-20 | 7/8" | Not Rated | 400 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1" | 440 | 1 1/4" | 1 1/2" | Ball Up, Ball Down | — | 5/16"-18 | 3/4" | Not Rated | 400 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 1/4"-20 | 11/16" | Not Rated | 400 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 5/16"-18 | 11/16" | Not Rated | 400 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1" | 75 | 1 3/8" | 1 3/4" | Ball Up, Ball Down | — | 3/8"-16 | 11/16" | Not Rated | 400 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1/2" | 65 | 11/16" | 7/8" | Ball Up, Ball Down | — | 1/4"-20 | 3/4" | Not Rated | 400 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M | 1" | 45 | 1 3/8" | 2 1/16" | Ball Up, Ball Down, Angled | Black | 5/16"-18 | 5/8" | 32 | 212 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polypropylene Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1" | 50 | 1 1/2" | 1 1/2" | Ball Up, Ball Down | — | 1/4"-20 | 7/8" | 0 | 190 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clean Room Stud-Mount Ball Transfers

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ball Dia. | Wt. Cap., lb. | Ht. | Dia. | Working Orientation | Housing Color | Thread Size | Stud Lg. | Min. | Max. | Clean Room Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 1/2 | 9/16" | 21/32" | Ball Up | White | M8 × 1.25 mm | 15/32" | 0 | 175 | Fed. Std. Class 1,000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK/Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2 1/2 | 9/16" | 19/32" | Ball Up | Beige | M8 × 1.25 mm | 15/32" | 0 | 260 | Fed. Std. Class 1,000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vespel® Polyimide Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vespel® Polyimide/Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 | 9/16" | 19/32" | Ball Up | Brown | M8 × 1.25 mm | 15/32" | 0 | 200 | Fed. Std. Class 1,000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oval Threaded-Hole-Mount Ball Knobs

Thread | Head | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp. | Dia. | Ht. | Hub Dia. | Insert Material | Temp. Range, ° F | 1-9 | 10-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 1/8" | 1 1/2" | 1/2" | Brass | -30 to 400 | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 1/8" | 1 1/2" | 1/2" | Brass | -30 to 400 | 0000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1/2" | 1 1/8" | 1 1/2" | 1/2" | Brass | -30 to 400 | 0000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 1/8" | 1 1/2" | 1/2" | Brass | -30 to 400 | 0000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 5/8" | 1 1/8" | 1 1/2" | 1/2" | Brass | -30 to 400 | 0000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 12 mm | 29 mm | 38 mm | 13 mm | Brass | -20 to 380 | 0000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 12 mm | 29 mm | 38 mm | 13 mm | Brass | -20 to 380 | 0000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 29 mm | 38 mm | 13 mm | Brass | -20 to 380 | 0000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Red Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1 1/8" | 1 1/2" | 1/2" | Brass | -30 to 400 | 00000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1 1/8" | 1 1/2" | 1/2" | Brass | -30 to 400 | 00000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1/2" | 1 1/8" | 1 1/2" | 1/2" | Brass | -30 to 400 | 00000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1 1/8" | 1 1/2" | 1/2" | Brass | -30 to 400 | 00000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 5/8" | 1 1/8" | 1 1/2" | 1/2" | Brass | -30 to 400 | 00000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 12 mm | 29 mm | 38 mm | 13 mm | Brass | -20 to 380 | 00000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 12 mm | 29 mm | 38 mm | 13 mm | Brass | -20 to 380 | 00000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 29 mm | 38 mm | 13 mm | Brass | -20 to 380 | 00000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

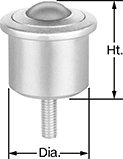

Washdown Stud-Mount Ball Transfers

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ball Dia. | Wt. Cap., lb. | Ht. | Dia. | Working Orientation | Housing Color | Thread Size | Stud Lg. | Min. | Max. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 525 | 1 3/4" | 2" | Ball Up, Ball Down, Angled | Black | M10 | 1 9/16" | -22 | 128 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glow-in-the-Dark Threaded-Hole-Mount Ball Knobs

Ball Transfers for Delicate Surfaces

Ball | Temp., ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Projection | Color | Wt. Cap., lb. | Working Orientation | Thread Size | Stud Lg. | Stem Material | Hardness | Hardness Rating | Min. | Max. | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyurethane Rubber Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 13/16" | Red | 30 | Ball Up, Ball Down, Angled | M14 | 1 21/32" | Zinc-Plated Steel | Durometer 92A | Extra Hard | 0 | 140 | Two Zinc-Plated Steel Locknuts | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32" | 2 17/32" | Red | 40 | Ball Up, Ball Down, Angled | M14 | 1 21/32" | Zinc-Plated Steel | Durometer 92A | Extra Hard | 0 | 140 | Two Zinc-Plated Steel Locknuts | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||