How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Ultra-High-Polish Gasket Fittings for Stainless Steel Tubing

- For Use With: Ammonia, Argon, Butane, Carbon Dioxide, Chloride, Fluoride, Fluorocarbon, Germane, Halide, Helium, Hydrogen, Krypton, Laser Gas, Natural Gas, Neon, Nitrogen, Oxygen, Silane, Sulfur Hexafluoride, Tungsten Hexafluoride, Xenon

- Temperature Range: -420° to 1000° F

- Tubing: Use with 316/316L stainless steel

- Compatible With: Swagelok® VCR

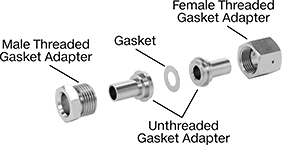

Polished to at least a 15 Ra finish on the inside, these fittings have an ultra-smooth interior surface that helps prevent contamination. Also known as ultra-high-purity fittings, they’re packed in a Class 100 clean room, cleaned, and double bagged. They are commonly used in semiconductor applications. Fittings use a metal gasket (sold separately), which generates fewer particles than a rubber gasket and creates a strong seal in high-pressure and ultra-high-vacuum applications. Fittings are 316 stainless steel for excellent corrosion resistance.

To assemble, place a gasket between the gasket ends before gently rotating the female-threaded fitting onto the male-threaded fitting. Tighten until 1/8 of a turn past finger tight.

Caps replace a female nut to close off the end of a line.

| For Tube OD | Material | Max. Pressure | Max. Vacuum | Environmental Rating | Each | |

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 000000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

Plugs replace a male nut to close off the end of a line.

| For Tube OD | Material | Max. Pressure | Max. Vacuum | Environmental Rating | Each | |

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Max. Vacuum | Lg. | Each | |

Male | ||||||

|---|---|---|---|---|---|---|

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | 1/2" | 00000000 | 00000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 17/32" | 00000000 | 0000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 23/32" | 0000000 | 0000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | 13/16" | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | 1" | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | 1 3/16" | 00000000 | 00000 |

Female | ||||||

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | 17/32" | 00000000 | 0000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 13/16" | 0000000 | 0000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | 7/8" | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | 1 1/8" | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | 1 11/32" | 00000000 | 00000 |

Retaining

Tabs

Hard and heat resistant, stainless steel gaskets can be used in a wider range of applications than nickel gaskets such as carbon monoxide and ozone. However, they’re harder to tighten than nickel gaskets, and they’ll wear down sealing surfaces more quickly.

Silver-plated stainless steel gaskets are softer than unfinished stainless steel gaskets, so they won’t wear down sealing surfaces as much, and they’re easier to tighten. However, they oxidize when exposed to air, and silver particles might flake off during assembly.

Nickel gaskets are softer than stainless steel gaskets, so they won’t wear down sealing surfaces as much, and they’re easier to tighten. They’re reactive to carbon monoxide and ozone, so they shouldn’t be used with those chemicals.

Gaskets with retaining tabs stay in place during installation, so you don’t have to hold the gasket while fastening fittings together. This also means they’re less likely to scratch or nick your fittings by rotating during installation.

| For Tube OD | Max. Vacuum | Environmental Rating | Each | |

316L Stainless Steel Gasket | ||||

|---|---|---|---|---|

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 0000 |

| 3/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

Silver-Plated 316L Stainless Steel Gasket | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

Nickel Gasket with Retaining Tabs | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

316L Stainless Steel Gasket with Retaining Tabs | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

Quick-Disconnect Tube Couplings for Chemicals

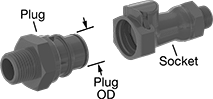

Couplings consist of a plug and a socket (sold separately) that join with a latch, so you can frequently connect and disconnect your line. To connect, insert the plug into the socket; to disconnect, press the latch on the socket and remove the plug. Plugs and sockets are polypropylene, which has excellent chemical, impact, and abrasion resistance.

Plugs and sockets with shut-off have a valve to stop the flow when the coupling is separated so fluid won’t spill from your line.

Note: For a complete coupling, order a plug and a socket with the same coupling size.

- For Use With: Ammonia, Ethanol, Phosphoric Acid (70%), Sodium Carbonate

- Temperature Range: 32° to 160° F

Barbed plugs insert into tubing and secure with a clamp.

Open Flow | With Shut-Off | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube ID | Coupling Size | Plug OD | Material | Color | Max. Pressure | Each | Each | ||

| 1/8" | 1/8 | 5/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 00000 | 00000000 | 000000 |

| 1/4" | 1/8 | 5/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 0000 | 00000000 | 00000 |

| 1/4" | 1/4 | 7/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 0000 | 00000000 | 00000 |

| 3/8" | 1/4 | 7/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 0000 | 00000000 | 00000 |

| 3/8" | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 0000 | 00000000 | 00000 |

| 1/2" | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 0000 | 00000000 | 00000 |

| 5/8" | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 0000 | 00000000 | 00000 |

| 3/4" | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

- For Use With: Ammonia, Ethanol, Phosphoric Acid (70%), Sodium Carbonate

- Temperature Range: 32° to 160° F

Barbed plugs insert into tubing and secure with a clamp.

Open Flow | With Shut-Off | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube ID | Coupling Size | Plug OD | Material | Color | Max. Pressure | Each | Each | ||

| 1/8" | 1/8 | 5/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 000000 | 00000000 | 000000 |

| 1/4" | 1/8 | 5/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 1/4" | 1/4 | 7/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 3/8" | 1/4 | 7/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 3/8" | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 1/2" | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

- For Use With: Ammonia, Ethanol, Phosphoric Acid (70%), Sodium Carbonate

- Temperature Range: 32° to 160° F

Open Flow | With Shut-Off | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Coupling Size | Plug OD | Material | Color | Max. Pressure | Each | Each | ||

NPT Threads | |||||||||

| 1/8 | 1/8 | 5/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 00000 | 00000000 | 000000 |

| 1/4 | 1/4 | 7/16" | Polypropylene Plastic | Beige | 120 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 3/8 | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 0000 | 00000000 | 00000 |

| 3/4 | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 1/2 | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 0000 | 00000000 | 00000 |

BSPT Threads | |||||||||

| 3/8 | 3/8 | 3/4" | Polypropylene Plastic | Gray | 60 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

High-Flow Quick-Disconnect Tube Couplings for Chemicals

- For Use With: Acetic Acid (20%), Ammonia, Carbon Dioxide, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Hydraulic Fluid (Petroleum Based), Hydrochloric Acid, Hydrogen Peroxide (30%), Kerosene, Methanol, Nitric Acid (20%), Potassium Hydroxide, Sodium Carbonate, Sodium Hydroxide (20%), Sulfuric Acid (75%), Synthetic Oil

- Temperature Range: 32° to 250° F

- Tubing: Use with soft or firm (Durometer 55A-95A) nylon plastic, polyethylene plastic, polypropylene plastic, polyurethane rubber, PVC plastic or TPE plastic

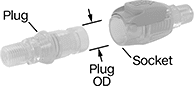

A spring-free flow path allows more chemicals to pass through these tube couplings at lower line pressures than other quick-disconnect couplings. This reduces turbulence, foaming, bubbles, and blockage. They have a shut-off valve that stops the flow when the coupling is disconnected, so chemicals won’t leak from your line. Unlike couplings with a button release, these have a safety slide to reduce accidental separation from bumps or drops. They are often used in laboratories, pharmaceutical facilities, and other sterile environments.

Made of PVDF, also known as Kynar, these couplings have excellent chemical and UV resistance at ambient and elevated temperatures. They also resist abrasion, impact, flames, and corrosion. Compared to other quick-disconnect couplings for chemicals, these couplings can withstand higher temperatures—all the way up to 250° F.

When you insert the plug into the socket, it’ll connect with a click. To disconnect, slide the latch on the socket and remove the plug.

Note: For a complete coupling, order a plug and a socket with the same coupling size.

They have a single barb that grips onto tubing or hose and provides a smooth clamping surface for extra-tight connections that minimize leaks.