How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

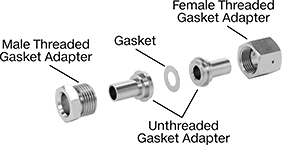

Ultra-High-Polish Gasket Fittings for Stainless Steel Tubing

- For Use With: Ammonia, Argon, Butane, Carbon Dioxide, Chloride, Fluoride, Fluorocarbon, Germane, Halide, Helium, Hydrogen, Krypton, Laser Gas, Natural Gas, Neon, Nitrogen, Oxygen, Silane, Sulfur Hexafluoride, Tungsten Hexafluoride, Xenon

- Temperature Range: -420° to 1000° F

- Tubing: Use with 316/316L stainless steel

- Compatible With: Swagelok® VCR

Polished to at least a 15 Ra finish on the inside, these fittings have an ultra-smooth interior surface that helps prevent contamination. Also known as ultra-high-purity fittings, they’re packed in a Class 100 clean room, cleaned, and double bagged. They are commonly used in semiconductor applications. Fittings use a metal gasket (sold separately), which generates fewer particles than a rubber gasket and creates a strong seal in high-pressure and ultra-high-vacuum applications. Fittings are 316 stainless steel for excellent corrosion resistance.

To assemble, place a gasket between the gasket ends before gently rotating the female-threaded fitting onto the male-threaded fitting. Tighten until 1/8 of a turn past finger tight.

Caps replace a female nut to close off the end of a line.

| For Tube OD | Material | Max. Pressure | Max. Vacuum | Environmental Rating | Each | |

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 000000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

Plugs replace a male nut to close off the end of a line.

| For Tube OD | Material | Max. Pressure | Max. Vacuum | Environmental Rating | Each | |

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Max. Vacuum | Lg. | Each | |

Male | ||||||

|---|---|---|---|---|---|---|

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | 1/2" | 00000000 | 00000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 17/32" | 00000000 | 0000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 23/32" | 0000000 | 0000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | 13/16" | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | 1" | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | 1 3/16" | 00000000 | 00000 |

Female | ||||||

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | 17/32" | 00000000 | 0000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 13/16" | 0000000 | 0000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | 7/8" | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | 1 1/8" | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | 1 11/32" | 00000000 | 00000 |

Retaining

Tabs

Hard and heat resistant, stainless steel gaskets can be used in a wider range of applications than nickel gaskets such as carbon monoxide and ozone. However, they’re harder to tighten than nickel gaskets, and they’ll wear down sealing surfaces more quickly.

Silver-plated stainless steel gaskets are softer than unfinished stainless steel gaskets, so they won’t wear down sealing surfaces as much, and they’re easier to tighten. However, they oxidize when exposed to air, and silver particles might flake off during assembly.

Nickel gaskets are softer than stainless steel gaskets, so they won’t wear down sealing surfaces as much, and they’re easier to tighten. They’re reactive to carbon monoxide and ozone, so they shouldn’t be used with those chemicals.

Gaskets with retaining tabs stay in place during installation, so you don’t have to hold the gasket while fastening fittings together. This also means they’re less likely to scratch or nick your fittings by rotating during installation.

| For Tube OD | Max. Vacuum | Environmental Rating | Each | |

316L Stainless Steel Gasket | ||||

|---|---|---|---|---|

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 0000 |

| 3/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

Silver-Plated 316L Stainless Steel Gasket | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

Nickel Gasket with Retaining Tabs | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

316L Stainless Steel Gasket with Retaining Tabs | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

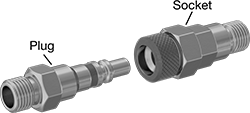

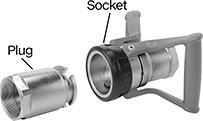

Quick-Disconnect Hose Couplings for Compressed Gas

Use these couplings to quickly link and unlink welding hoses, torches, and pressure regulators. They consist of a plug and socket that are sold together as a set of two—you’ll get one right-hand connection for oxygen and one left-hand connection for fuel gas. The connections are noninterchangeable and color coded so you can’t mix lines. The male threaded ends attach to threaded welding hose, and the female threaded ends attach to a torch or pressure regulator. To connect couplings, push the plug into the socket; the sleeve on the socket has a spring-loaded lock for gas-tight connections. To disconnect, pull back on the socket sleeve and twist to release the plug. The sockets have a shut-off valve that stops the flow when the coupling is separated so gas won’t leak from the line. The sockets also have a built-in check valve to prevent gas backflow. Couplings are also known as CGA (Compressed Gas Association) couplings. They are brass for good corrosion resistance.

Couplings with left-hand threads are identified with a notch in the nut.

Note: Couplings have a CGA number that corresponds to a specific type of gas. Make sure the CGA number of the coupling matches the CGA number of your tank and other system components.

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

- Specifications Met: OSHA 29 CFR 1915.55, OSHA 29 CFR 1917.152, OSHA 29 CFR 1926.350, UL Listed

| Includes | Gas Fitting Size | Thread Size | Thread Type | Thread Direction | For Use With | Each | |

| One CGA 022 Coupling Adapter (Male Hose Plug × Female Torch Socket) One CGA 023 Coupling Adapter (Male Hose Plug × Female Torch Socket) | B | 9/16"-18 | UN/UNF (CGA) | Right Hand (CGA 022), Left Hand (CGA 023) | Acetylene, Butane, Fuel Gases, LP Gas, Natural Gas, Oxygen, Propane | 000000 | 0000000 |

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

- Specifications Met: OSHA 29 CFR 1915.55, OSHA 29 CFR 1917.152, OSHA 29 CFR 1926.350, UL Listed

| Includes | Gas Fitting Size | Thread Size | Thread Type | Thread Direction | For Use With | Each | |

| One CGA 022 Coupling Adapter (Male Hose Plug × Female Regulator Socket) One CGA 023 Coupling Adapter (Male Hose Plug × Female Regulator Socket) | B | 9/16"-18 | UN/UNF (CGA) | Right Hand (CGA 022), Left Hand (CGA 023) | Acetylene, Butane, Fuel Gases, LP Gas, Natural Gas, Oxygen, Propane | 000000 | 0000000 |

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

- Specifications Met: OSHA 29 CFR 1915.55, OSHA 29 CFR 1917.152, OSHA 29 CFR 1926.350, UL Listed

| Includes | Gas Fitting Size | Thread Size | Thread Type | Thread Direction | For Use With | Each | |

| One CGA 022 Coupling Adapter (Male Hose Plug × Male Hose Socket) One CGA 023 Coupling Adapter (Male Hose Plug × Male Hose Socket) | B | 9/16"-18 | UN/UNF (CGA) | Right Hand (CGA 022), Left Hand (CGA 023) | Acetylene, Butane, Fuel Gases, LP Gas, Natural Gas, Oxygen, Propane | 000000 | 0000000 |

Threaded Hose Fittings for Compressed Gas

Use these fittings to connect welding hose to pressure regulators and torches. They are also known as CGA (Compressed Gas Association) fittings. Fittings are brass for good corrosion resistance.

Fittings with left-hand threads are identified with a notch in the nut.

Note: Fittings have a CGA number that corresponds to a specific type of gas. Choose a fitting with the same CGA number as your tank and other system components.

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

| CGA Number | Gas Fitting Size | Thread Size | Thread Type | Thread Direction | Chain Lg. | For Use With | Each | |

Brass | ||||||||

|---|---|---|---|---|---|---|---|---|

| 023 | B | 9/16"-18 | UN/UNF (CGA) | Left Hand | 6" | Acetylene, Butane, Fuel Gases, LP Gas, Natural Gas, Propane | 0000000 | 00000 |

Minimal-Spill Push-and-Turn Hose Couplings for Natural and LP Gas

Often used for loading and unloading gas tankers, these couplings are tough enough to handle frequent connections and designed to be virtually spill-free. The socket has a rubber lip and large handles that protect it if it’s dropped. To connect, simply push the plug into the socket and twist 90°. Also known as dry disconnects and double-shut off couplings, both the plug and the socket have a shut-off valve that holds your line when they’re separated. A close fit between the plug and socket means there's little room for gas to leak when you disconnect them. This further reduces the risk of leaks and burns from contact with extremely cold gases such as liquified petroleum (LP). The socket swivels, so you won’t have to twist your hose to attach the plug. Made of stainless steel, these couplings resist corrosion from harsh chemicals and salt water.

A complete coupling consists of a plug and a socket (both sold separately).