How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

High-Purity PVDF Pipe Fittings for Corrosive Chemicals

Made of PVDF that’s finished to a 12 Ra smoothness, these fittings handle some of the harshest chemicals without leaching contaminants into your line. They won’t accumulate particles and are easy to clean, thanks to their smoothness. Comparable to Kynar, these fittings handle most organic solvents that would dissolve CPVC, and chlorine or nitric acid that would weaken polypropylene. You can use them at higher temperatures than CPVC and polypropylene. These fittings meet UL 94 V-0 and FM standards for flame retardance. They’re also FDA compliant for direct contact with food, and they meet ASTM requirements for dimensions and tolerances.

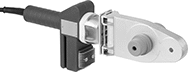

Connect them to pipe with socket fusion welding for a strong, permanent bond. Use a socket fusion tool with a heater bushing (sold separately) that matches your pipe size.

- For Use With: Chlorine, Deionized Water, Hydrochloric Acid, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: -40° to 270° F

- Specifications Met: ASTM D3261, FDA Compliant 21 CFR 177.2510, FM 4910, UL 94 V-0

- Pipe Nipples and Pipe: Use SDR 21 PVDF Plastic

- Flanges: Use PVDF Plastic

| Pipe Size | Socket Dp. | Material | Color | Max. Pressure | Each | |

| 1/2 | 37/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 |

| 3/4 | 5/8" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 00000 |

| 1 | 45/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 59/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 |

| 2 | 1 5/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 |

- For Use With: Chlorine, Deionized Water, Hydrochloric Acid, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: -40° to 270° F

- Specifications Met: ASTM D3222, FDA Compliant 21 CFR 177.2510, FM 4910, UL 94 V-0

- Seal Material: Viton® Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

Add a ball valve to control the flow in your line.

| Pipe Size | Flow Coefficient (Cv) | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Color | Max. Pressure | Each | |

PVDF Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | White | 230 psi @ 72° F | 0000000 | 0000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | White | 230 psi @ 72° F | 0000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | White | 230 psi @ 72° F | 0000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | White | 230 psi @ 72° F | 0000000 | 00000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | White | 230 psi @ 72° F | 0000000 | 00000000 |

| Each | ||

| 00000000 | 0000000 |

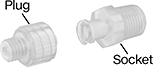

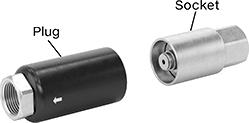

Luer Lock Tube Couplings for Plastic and Rubber Tubing—Chemicals

- For Use With: Acetic Acid, Bleach, Ethanol, Hydrochloric Acid, Nitric Acid, Phosphoric Acid, Sulfuric Acid

- Tubing: Use with soft (Durometer 40A-65A) PVC plastic or silicone rubber

A staple in labs, these couplings are highly versatile, fitting any luer lock plug, socket, syringe, or needle. They lock together with a push and turn, so they work well in lines that are frequently disconnected. Use them in low-pressure applications. They have a compact body for installation in tight spaces. Made of PVDF, they resist most acids, alcohols, and organic solvents. PVDF is also known as Kynar.

Note: For a complete coupling, order a plug and a socket.

| For Tube ID | Material | Color | Clarity | Max. Pressure | Locking Ring Included | Pkg. Qty. | Pkg. | |

| 1/16" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 000000 |

| 3/32" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| 1/8" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| 5/32" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| 1/4" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| Thread Size | Material | Color | Clarity | Max. Pressure | Locking Ring Included | Pkg. Qty. | Pkg. | |

UN/UNF (SAE Straight) Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4"-28 | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 000000 |

| Material | Color | Clarity | Max. Pressure | Pkg. Qty. | Pkg. | |

| PVDF Plastic | White | Semi-Clear | Not Rated | 10 | 0000000 | 00000 |

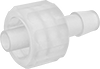

Plastic Push-to-Connect Tube Fittings for Chemicals

- For Use With: Inch: Alcohol, Hydrochloric Acid, Nitric Acid, Sodium Carbonate, Sulfuric Acid

Metric: Acetic Acid, Alcohol, Arsenic Acid, Benzoic Acid, Fluoboric Acid, Sodium Carbonate, Sulfuric Acid - Temperature Range: Inch: 0° to 270° F

Metric: 32° to 175° F - Tubing: Use with hard (Durometer 55D-60D) FEP plastic

Also known as instant fittings, these chemical-resistant plastic fittings connect to tubing with a push. An internal gripping ring holds the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. Use these fittings in low-pressure applications.

PVDF fittings offer excellent chemical resistance, and can be used with hydrochloric acid and nitric acid. They withstand temperatures up to 270° F, higher than other push-to-connect fittings for chemicals. They are produced in a clean room and are bagged individually to prevent dirt and moisture from contaminating the inside. PVDF is also known as Kynar.

Caps fit over a tube stem end of a fitting or a piece of tubing.

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 1/4" | PVDF Plastic | Black | Gray | 300 psi @ 72° F | 0000000 | 00000 |

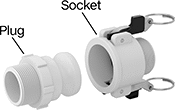

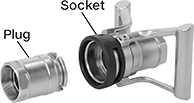

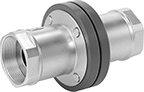

Plastic Cam-and-Groove Hose Couplings for Chemicals and Petroleum

Made of plastic, these couplings are lighter in weight than metal cam-and-groove hose couplings, yet have the chemical resistance to withstand gasoline and other harsh substances. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

Plugs with male threaded end are also known as F adapters.

Plugs with female threaded end are also known as A adapters.

Plugs with barbed end are also known as E adapters. Insert the barbed end into rubber hose and secure with a clamp.

Sockets with locking levers prevent accidental disconnection. The locking pins engage automatically when the coupling is connected. Press the locking pins simultaneously to disengage.

PVDF plugs and sockets have better corrosion and chemical resistance than nylon plugs and sockets. Use them when your application involves harsh acids and solvents.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Specifications Met: Fed. Spec. A-A-59326

| Coupling Size | Plug OD | Pipe Size | Thread Type | Color | Max. Pressure | Each | |

PVDF Plastic | |||||||

|---|---|---|---|---|---|---|---|

| 3/4 | 1 1/4" | 1/2 | NPT | White | 125 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 1 1/4" | 3/4 | NPT | White | 125 psi @ 72° F | 00000000 | 00000 |

| 1 | 1 7/16" | 1 | NPT | White | 125 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 2 1/8" | 1 1/4 | NPT | White | 100 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 2 1/8" | 1 1/2 | NPT | White | 100 psi @ 72° F | 0000000 | 00000 |

| 2 | 2 1/2" | 2 | NPT | White | 100 psi @ 72° F | 0000000 | 00000 |

| 3 | 3 5/8" | 3 | NPT | White | 50 psi @ 72° F | 0000000 | 000000 |

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Specifications Met: Fed. Spec. A-A-59326

| Coupling Size | Plug OD | Pipe Size | Thread Type | Color | Max. Pressure | Each | |

PVDF Plastic | |||||||

|---|---|---|---|---|---|---|---|

| 3/4 | 1 1/4" | 1/2 | NPT | White | 125 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 1 1/4" | 3/4 | NPT | White | 125 psi @ 72° F | 00000000 | 00000 |

| 1 | 1 7/16" | 1 | NPT | White | 125 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 2 1/8" | 1 1/4 | NPT | White | 100 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 2 1/8" | 1 1/2 | NPT | White | 100 psi @ 72° F | 0000000 | 00000 |

| 2 | 2 1/2" | 2 | NPT | White | 100 psi @ 72° F | 0000000 | 00000 |

| 2 | 2 1/2" | 2 | BSPP | White | 150 psi @ 72° F | 0000000 | 00000 |

| 3 | 3 5/8" | 3 | NPT | White | 50 psi @ 72° F | 0000000 | 00000 |

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

| Coupling Size | Plug OD | For Hose ID | Color | Max. Pressure | Each | |

PVDF Plastic | ||||||

|---|---|---|---|---|---|---|

| 3/4 | 1 1/4" | 1/2" | White | 125 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 1 1/4" | 3/4" | White | 125 psi @ 72° F | 00000000 | 00000 |

| 1 | 1 7/16" | 1" | White | 125 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 2 1/8" | 1 1/4" | White | 100 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 2 1/8" | 1 1/2" | White | 100 psi @ 72° F | 0000000 | 00000 |

| 2 | 2 1/2" | 2" | White | 100 psi @ 72° F | 0000000 | 00000 |

| 3 | 3 5/8" | 3" | White | 50 psi @ 72° F | 0000000 | 00000 |

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Specifications Met: Fed. Spec. A-A-59326

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Specifications Met: Fed. Spec. A-A-59326

Caps | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | |||||||||

| Coupling Size | Socket ID | Color | No. of | Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | ||

PVDF Plastic | ||||||||||

| 1 1/2 | 2 1/8" | White | 2 | 304 Stainless Steel | 100 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 000000 |

| 2 | 2 1/2" | White | 2 | 304 Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 |

| 3 | 3 5/8" | White | 2 | 304 Stainless Steel | 50 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 00000 |

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: 125 psi @ 72° F

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Specifications Met: Fed. Spec. A-A-59326

Minimal-Spill Push-and-Turn Hose Couplings for Chemicals

Quickly connect and disconnect hose lines used with a variety of chemicals, from adhesives to isopropyl alcohol and ink. Any part of these couplings that contacts fluid is made from 316 stainless steel, C-276 Hastelloy, PTFE, or fluoroelastomer to withstand the chemicals in your line. Tough enough to handle frequent use, these couplings are designed to be virtually spill free. Also known as dry disconnects and double-shut off couplings, both the plug and the socket have a shut-off valve that stops the flow of liquids when they’re separated. To connect, push the plug into the socket and lock with a quarter turn. The socket swivels, so you won’t have to twist your hose to attach the plug. It also has a rubber lip and large handles to prevent damage if it’s dropped.

A complete coupling consists of a plug and a socket (both sold separately). They’re compatible with MannTek, Avery Hardoll, Todo-matic, and other dry-disconnect couplings that meet NATO standard STANAG 3756.

316 stainless steel couplings have excellent corrosion resistance.

- For Use With:

Aluminum: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Varnish, Vegetable Oil

316 Stainless Steel: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil - Maximum Pressure:

Aluminum: 230 psi @ 72° F

316 Stainless Steel: 360 psi @ 72° F - Temperature Range: -15° to 400° F

- For Use With:

Aluminum: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Varnish, Vegetable Oil

316 Stainless Steel: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil - Maximum Pressure:

Aluminum: 230 psi @ 72° F

316 Stainless Steel: 360 psi @ 72° F - Temperature Range: -15° to 400° F

Breakaway Hose Couplings for Chemicals and Petroleum

Minimize chemical and petroleum spills during accidental disconnects, such as a driver pulling away during loading. These couplings have a shut-off valve on each half to stop flow when they’re separated. Attach one end to your hose and the other to a supply pipe or a second hose.

316 stainless steel couplings have excellent corrosion resistance.

2 NPT and 3 NPT couplings have bolts designed to break before your hose does. They can be repaired with replacement bolt kits and replacement seal kits (both sold separately).

- For Use With: See table

- Maximum Pressure: See table

- Temperature Range: See table

Pipe Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| Plug | Socket | Max. Pressure | Temp. Range, °F | Repairable | For Use With | Each | ||

NPT Female Threaded Pipe | ||||||||

316 Stainless Steel Plug and Socket | ||||||||

| B | 2 | 2 | 360 psi @ 72° F | -50° to 480° | Repairable | Acetone, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil | 0000000 | 000000000 |

| B | 3 | 3 | 360 psi @ 72° F | -50° to 480° | Repairable | Acetone, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil | 0000000 | 00000000 |