How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Plastic Push-to-Connect Tube Fittings for Chemicals

- For Use With: Inch: Alcohol, Hydrochloric Acid, Nitric Acid, Sodium Carbonate, Sulfuric Acid

Metric: Acetic Acid, Alcohol, Arsenic Acid, Benzoic Acid, Fluoboric Acid, Sodium Carbonate, Sulfuric Acid - Temperature Range: Inch: 0° to 270° F

Metric: 32° to 175° F - Tubing: Use with hard (Durometer 55D-60D) FEP plastic

Also known as instant fittings, these chemical-resistant plastic fittings connect to tubing with a push. An internal gripping ring holds the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. Use these fittings in low-pressure applications.

PVDF fittings offer excellent chemical resistance, and can be used with hydrochloric acid and nitric acid. They withstand temperatures up to 270° F, higher than other push-to-connect fittings for chemicals. They are produced in a clean room and are bagged individually to prevent dirt and moisture from contaminating the inside. PVDF is also known as Kynar.

Caps fit over a tube stem end of a fitting or a piece of tubing.

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 1/4" | PVDF Plastic | Black | Gray | 300 psi @ 72° F | 0000000 | 00000 |

Compression Fittings for Plastic Tubing—Chemicals

- For Use With: PFA Plastic: Hydrochloric Acid, Sulfuric Acid

PTFE Plastic: Alcohol, Ammonia, Benzoic Acid, Bleach, Bromine, Coolant, Fluoboric Acid, Hydrochloric Acid, Hydrofluoric Acid, Nitric Acid, Organic Solvents, Sodium Carbonate, Sulfuric Acid - Temperature Range: PFA Plastic: 0° to 350° F

PTFE Plastic: -40° to 185° F - Tubing: PFA Plastic: Use with hard (Durometer 50D-65D) PFA or PTFE plastic

PTFE Plastic: Use with hard (Durometer 60D) PFA or PTFE plastic

A sleeve (ferrule) compresses the tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings. Fittings that include a gripper sleeve on the tubing create an even tighter seal.

PFA fittings stand up to harsh substances. They’re made through a melting process.

Luer Lock Tube Couplings for Plastic and Rubber Tubing—Chemicals

- For Use With: Acetic Acid, Bleach, Ethanol, Hydrochloric Acid, Nitric Acid, Phosphoric Acid, Sulfuric Acid

- Tubing: Use with soft (Durometer 40A-65A) PVC plastic or silicone rubber

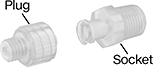

A staple in labs, these couplings are highly versatile, fitting any luer lock plug, socket, syringe, or needle. They lock together with a push and turn, so they work well in lines that are frequently disconnected. Use them in low-pressure applications. They have a compact body for installation in tight spaces. Made of PVDF, they resist most acids, alcohols, and organic solvents. PVDF is also known as Kynar.

Note: For a complete coupling, order a plug and a socket.

| For Tube ID | Material | Color | Clarity | Max. Pressure | Locking Ring Included | Pkg. Qty. | Pkg. | |

| 1/16" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 000000 |

| 3/32" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| 1/8" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| 5/32" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| 1/4" | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 00000 |

| Thread Size | Material | Color | Clarity | Max. Pressure | Locking Ring Included | Pkg. Qty. | Pkg. | |

UN/UNF (SAE Straight) Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4"-28 | PVDF Plastic | White | Semi-Clear | Not Rated | With Locking Ring | 10 | 0000000 | 000000 |

| Material | Color | Clarity | Max. Pressure | Pkg. Qty. | Pkg. | |

| PVDF Plastic | White | Semi-Clear | Not Rated | 10 | 0000000 | 00000 |