Filter by

Fastener Head Type

Spring Plunger Nose Type

Nose Material

Body Material

Locking Type

System of Measurement

Performance

Plunger Locking Type

Material

Compressed Nose Force

Extended Nose Force

End Type

Export Control Classification Number (ECCN)

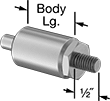

Add-a-Handle Retractable Spring Plungers

|

Customize these spring plungers with a handle (not included) that's the size, shape, texture, and color you want. Retractable spring plungers give you the control to position, align, and lock components as needed for your job.

Steel Nose—The strongest, most wear-resistant noses, these won't deform from stress and vibration. Steel is best for dry environments, however, since moisture will cause it to rust.

18-8 Stainless Steel Nose—The choice for wet and outdoor environments, 18-8 stainless steel resists rusting. It's strong enough for most jobs, but won't withstand stress and vibration as well as steel.

Twist-to-Lock—Free up both hands to adjust your workpiece or switch out parts without the plunger springing back and getting in the way. Pull back the handle and twist to lock the nose in its retracted position.

Nose | Nose Force, lbf | Body | Handle End Thread | Nonlocking | Twist-to-Lock | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Size | Lg. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 0.41" | 0.094" | 0.104" | 1 | 3 | Steel | 0.81" | 10-32 | 15/64" | ——— | 0 | 7805A11 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.5" | 0.125" | 0.124" | 1 | 5 | Steel | 0.94" | 10-32 | 15/64" | ——— | 0 | 7805A12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.63" | 0.188" | 0.155" | 1.5 | 6 | Steel | 1.25" | 1/4"-20 | 11/32" | ——— | 0 | 7805A13 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.75" | 0.219" | 0.186" | 1.5 | 8 | Steel | 1.47" | 5/16"-18 | 13/32" | ——— | 0 | 7805A14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 0.67" | 0.197" | 0.197" | 1.6 | 3.6 | Black-Oxide Steel | 1.3" | M5 × 0.8 mm | 1/4" | 8507A14 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 0.79" | 0.236" | 0.236" | 1.5 | 3.4 | Black-Oxide Steel | 1.65" | M6 × 1 mm | 25/64" | 8507A15 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 0.88" | 0.25" | 0.249" | 2.5 | 10 | Steel | 1.69" | 3/8"-16 | 7/16" | ——— | 0 | 7805A15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1.02" | 0.315" | 0.315" | 2.7 | 6.9 | Black-Oxide Steel | 2.13" | M8 × 1.25 mm | 31/64" | 8507A16 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 0.41" | 0.094" | 0.104" | 1 | 3 | 18-8 Stainless Steel | 0.81" | 10-32 | 15/64" | ——— | 0 | 7806A11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.5" | 0.125" | 0.124" | 1 | 5 | 18-8 Stainless Steel | 0.94" | 10-32 | 15/64" | ——— | 0 | 7806A12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.63" | 0.188" | 0.155" | 1.5 | 6 | 18-8 Stainless Steel | 1.25" | 1/4"-20 | 11/32" | ——— | 0 | 7806A13 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.75" | 0.219" | 0.186" | 1.5 | 8 | 18-8 Stainless Steel | 1.47" | 5/16"-18 | 13/32" | ——— | 0 | 7806A14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 0.88" | 0.25" | 0.249" | 2.5 | 10 | 18-8 Stainless Steel | 1.69" | 3/8"-16 | 7/16" | ——— | 0 | 7806A15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Add-a-Handle Weld-On Retractable Spring Plungers

|

Thread on whichever handle (not included) springs to mind to control when and how you retract the nose. Since they weld in place, these spring plungers have the strongest hold for aligning, securing, and positioning components on heavy machinery. They can do everything from locking attachments on forklifts to holding dies in place on industrial presses. To change your setup, unthread the spring plunger from the old welded-on barrel and thread it into a new one.

Zinc-Plated Steel Nose—The strongest, most wear-resistant noses, these won't deform from stress and vibration. They withstand occasional exposure to moisture.

18-8 Stainless Steel Nose—The choice for wet and outdoor environments, 18-8 stainless steel resists rusting. It's strong enough for most jobs, but won't withstand stress and vibration as well as steel.

Spring Plungers | Replacement Barrel Sleeves | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Body | Handle End Thread | Nonlocking | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Lg. | Dia. | Material | Wd. | Lg. | Size | Lg. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | Steel | 1" | 1.5" | 3/8"-16 | 1/2" | 90222A742 | 000000 | 90222A804 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 1.5" | 3/8"-16 | 1/2" | 90222A760 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 2.25" | 3/8"-16 | 1/2" | 90222A796 | 00000 | 90222A805 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | 18-8 Stainless Steel | 1" | 1.5" | 3/8"-16 | 1/2" | 91712A556 | 00000 | 91712A582 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 1.5" | 3/8"-16 | 1/2" | 91712A564 | 00000 | 91712A582 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 2.25" | 3/8"-16 | 1/2" | 91712A580 | 00000 | 91712A583 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

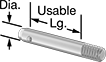

Add-a-Handle Quick-Release Pins

Customize these pins with a knob or handle (not included) that's the size, shape, texture, and color you want. Pins have a retaining ball that holds them in place until you pull to remove.

Corrosion-Resistant Stainless Steel

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these pins resist rusting. They are strong enough to join most components but won't withstand stress and vibration as well as steel.

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Usable Lg. | Dia. at Extended Ball Ht. | Size | Lg. | Single Shear Breaking Strength, lbf | Min. Hardness | Ball Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.204" | 10-32 | 5/16" | 2,300 | Rockwell B85 | Stainless Steel | 93460A005 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.204" | 10-32 | 5/16" | 2,300 | Rockwell B85 | Stainless Steel | 93460A010 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.204" | 10-32 | 5/16" | 2,300 | Rockwell B85 | Stainless Steel | 93460A015 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.204" | 10-32 | 5/16" | 2,300 | Rockwell B85 | Stainless Steel | 93460A020 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.286" | 1/4"-20 | 3/8" | 4,500 | Rockwell B85 | Stainless Steel | 93460A125 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.286" | 1/4"-20 | 3/8" | 4,500 | Rockwell B85 | Stainless Steel | 93460A130 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.286" | 1/4"-20 | 3/8" | 4,500 | Rockwell B85 | Stainless Steel | 93460A135 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.286" | 1/4"-20 | 3/8" | 4,500 | Rockwell B85 | Stainless Steel | 93460A140 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.286" | 1/4"-20 | 3/8" | 4,500 | Rockwell B85 | Stainless Steel | 93460A145 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.356" | 5/16"-18 | 3/8" | 7,200 | Rockwell B85 | Stainless Steel | 93460A250 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.356" | 5/16"-18 | 3/8" | 7,200 | Rockwell B85 | Stainless Steel | 93460A255 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.426" | 3/8"-16 | 1/2" | 9,300 | Rockwell B85 | Stainless Steel | 93460A375 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.426" | 3/8"-16 | 1/2" | 9,300 | Rockwell B85 | Stainless Steel | 93460A380 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.426" | 3/8"-16 | 1/2" | 9,300 | Rockwell B85 | Stainless Steel | 93460A385 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.57" | 1/2"-13 | 1/2" | 15,700 | Rockwell B85 | Stainless Steel | 93460A495 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.57" | 1/2"-13 | 1/2" | 15,700 | Rockwell B85 | Stainless Steel | 93460A505 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.57" | 1/2"-13 | 1/2" | 15,700 | Rockwell B85 | Stainless Steel | 93460A510 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||