Filter by

Thread Size

Nose Material

Locking Type

Drive Style

Body Material

Extended Nose Force

Mount Type

Compressed Nose Force

System of Measurement

Thread Type

Body Finish

Material

Thread Spacing

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Drive Size

Threadlocker Type

Performance

Long-Nose Spring Plungers

|  | |

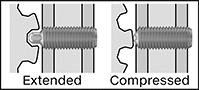

Lock heavy moving parts securely in place. Often used in indexing applications, these have a longer nose than ball-nose spring plungers to withstand greater side forces without disengaging. The nose compresses when a part presses against it, and then pops out into deep notches or grooves for a strong hold.

Spring plungers are available with or without a threadlocker. Those with a threadlocker won't wiggle loose from vibration. Spring plungers without a threadlocker are easier to remove.

Steel Nose—The strongest, most wear-resistant noses, these won't deform from stress and vibration. Steel is best for dry environments, however, since moisture will cause it to rust.

18-8 Stainless Steel Nose—The choice for wet and outdoor environments, 18-8 stainless steel resists rusting. It's strong enough for most jobs, but won't withstand stress and vibration as well as steel.

316 Stainless Steel Nose—With the best corrosion resistance of all, 316 stainless steel stands up to harsh weather, salt water, and chemicals. The nose is strong enough for most jobs, but won't withstand stress and vibration as well as steel.

Brass Nose—Similar to 18-8 stainless steel, brass is corrosion resistant enough to stand up to wet environments. Since brass is softer than other metals, these noses are less likely to dent surfaces, however, they could deform under high stress.

Acetal Nose—The best plastic for damp and wet environments, acetal won't swell or lose strength if exposed to moisture. These noses are extra soft to avoid scratching delicate surfaces. They are best for use on soft materials, such as aluminum.

Spring Plungers | Spring Plunger Drivers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Nose Force, lbf | Body | Drive Style | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

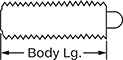

Thread Size | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Front | Back | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.036" | 0.046" | 0.5 | 1.5 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | Slotted | 3126A69 | 00000 | 3382A11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | Black-Oxide Steel | 0.53" | — | Hex | 8495A19 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 3126A1 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | — | 3126A2 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | Black-Oxide Steel | 0.53" | — | Hex | 8495A12 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | Black-Oxide Steel | 0.53" | — | Hex | 8495A11 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 3126A3 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.046" | 0.5 | 3.5 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | — | 3126A75 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | 18-8 Stainless Steel | 0.53" | — | Hex | 8476A41 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | 18-8 Stainless Steel | 0.53" | Spring Plunger Driver | — | 84975A36 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 8490A68 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | 18-8 Stainless Steel | 0.38" | Spring Plunger Driver | — | 84975A37 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | 18-8 Stainless Steel | 0.53" | — | Hex | 8476A33 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | — | 8490A55 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | 18-8 Stainless Steel | 0.53" | — | Hex | 8476A32 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | 18-8 Stainless Steel | 0.53" | Spring Plunger Driver | — | 84975A39 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 8490A54 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | 316 Stainless Steel | 0.38" | Spring Plunger Driver | — | 8688A11 | 00000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | Brass | 0.38" | Spring Plunger Driver | — | 8689A11 | 00000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.036" | 0.046" | 0.5 | 1.5 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | Slotted | 8499A52 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | 18-8 Stainless Steel | 0.53" | — | Hex | 2177A41 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | Black-Oxide Steel | 0.53" | — | Hex | 2467A34 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 8499A46 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | 18-8 Stainless Steel | 0.53" | — | Hex | 2177A63 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | Black-Oxide Steel | 0.53" | — | Hex | 2467A32 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | 18-8 Stainless Steel | 0.53" | — | Hex | 2177A42 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | Black-Oxide Steel | 0.53" | — | Hex | 2467A31 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 8499A47 | 00000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.046" | 0.5 | 3.5 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | — | 8499A48 | 0000 | 3382A11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

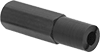

Spring Plunger Drivers

|

Install spring plungers from the nose end without depressing the nose.

For Thread Size | For Spring Plunger Nose Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | Ball, Long | 3382A11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||