About Conduit

More

Mini Splitters

Simplify wiring and reduce the number of cords in your automation setup. These splitters create a branch off a main cord or connect multiple devices with a mini connection to a single port in a junction box or I/O module. A threaded housing securely mates with other mini connectors to keep out contaminants and won’t come loose from shaking or vibration. They have a standard pole layout and housing thread size to reduce the chance you’ll mis-mate connectors.

When mated, these connectors meet IP68 and NEMA 6P for protection against dust, submersion, washdowns, and weather.

Caps protect connectors and maintain their IP and NEMA ratings when not in use.

Thread adapters connect plugs and sockets that both have internal threads.

Plug | Sockets | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Housing Thread Size | Number of Poles | Face Dia. | Housing Thread Size | Voltage | Current | Housing Material | Temp. Range, °F | Environmental Rating | Specifications Met | Each | |

Plug (UNS External Thread) × Sockets (UNS Internal Thread) | |||||||||||||

| 2 | 0.55" | 7/8"-16 | 2 | 0.55" | 7/8"-16 | 600V AC/600V DC | 13A | Polyurethane Rubber | 0° to 175° | IP68, NEMA 6P | UL Recognized Component, CSA Certified | 0000000 | 000000 |

| 3 | 0.55" | 7/8"-16 | 3 | 0.55" | 7/8"-16 | 600V AC/600V DC | 13A | Polyurethane Rubber | 0° to 175° | IP68, NEMA 6P | UL Recognized Component, CSA Certified | 0000000 | 00000 |

| 4 | 0.55" | 7/8"-16 | 4 | 0.55" | 7/8"-16 | 600V AC/600V DC | 10A | Polyurethane Rubber | 0° to 175° | IP68, NEMA 6P | UL Recognized Component, CSA Certified | 0000000 | 00000 |

| 5 | 0.55" | 7/8"-16 | 5 | 0.55" | 7/8"-16 | 600V AC/600V DC | 8A | Polyurethane Rubber | 0° to 175° | IP68, NEMA 6P | UL Recognized Component, CSA Certified | 0000000 | 00000 |

| 6 | 0.55" | 7/8"-16 | 6 | 0.55" | 7/8"-16 | 600V AC/600V DC | 8A | Polyurethane Rubber | 0° to 175° | IP68, NEMA 6P | UL Recognized Component, CSA Certified | 0000000 | 000000 |

Thread | |||||

|---|---|---|---|---|---|

| Size | Type | Material | Temp. Range, °F | Each | |

External Thread | |||||

| 7/8"-16 | UNS | Aluminum | -4° to 190° | 00000000 | 00000 |

M35 Power Connectors

Power robotic arms and other high-amperage machines in motor controls, conveyors, and sorting and packaging systems from your main M35 power line. Quick to attach and detach, these connectors are easy to install and maintain.

UL and C-UL listed, all meet American and Canadian safety standards. They’re UL 2237 rated, which means you can use them in motor circuits that extend beyond their circuit breaker or fuse. IP and NEMA rated when mated, these connectors also resist corrosion and seal out dust and water from weather and washdowns. They can even be under water for brief periods of time.

Connecting tees link multiple pieces of equipment with M35 connections. Reducing tees connect equipment with M35 connections to equipment with M22 connections.

Add a cap to shield these connectors from dust when they’re not in use.

Optional locking clips stop your connector from coming loose when powering devices with high amperage.

Housing Thread | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

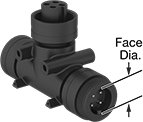

| No. of Poles | Face Dia. | Size | Type | Current, A | Voltage | Color | Housing Material | Temp. Range, °F | Environmental Rating | Each | |

Straight Male Plug (External Thread) × Straight Female Socket (Internal Thread) × Straight Female Socket (Internal Thread) | |||||||||||

| 4 | 0.87" | 1 3/8"-16 | UNS | 25 | 600V AC/600V DC | Black | PVC Plastic | -40° to 190° | NEMA 6P, IP67 | 0000000 | 0000000 |

Face Dia. | Housing Thread Size | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

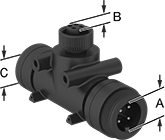

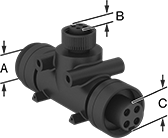

| No. of Poles | (A) | (B) | (C) | (A) | (B) | (C) | Current | Voltage | Color | Housing Material | Temp. Range, °F | Environmental Rating | Each | |

Straight Male Plug (External Thread) × Straight Female Socket (Internal Thread) × Straight Female Socket (Internal Thread) | ||||||||||||||

| 4 | 0.87" | 0.59" | 0.87" | 1 3/8"-16 UNS | 7/8"-16 UNS | 1 3/8"-16 UNS | 15A | 600V AC/600V DC | Black | PVC Plastic | -40° to 190° | NEMA 6P, IP67 | 0000000 | 000000 |

| Color | Material | Each | |

| Black | PVC Plastic | 0000000 | 00000 |

Access Ports for Metal Conduit

Also known as conduit bodies, these ports provide access to wire and cable inside conduit for pulling, splicing, and maintenance. They are also used to change the direction of a run. Connect to thick-wall (rigid) metal conduit. Aluminum and zinc-plated iron ports can connect to medium-wall (IMC) conduit. Ports with a set screw also connect to thin-wall (EMT) steel conduit without a compression connector.

All are corrosion resistant. 316 stainless steel ports offer the best corrosion resistance.

Ports that can be configured as a straight, tee, or 90° elbow come with multiple cover plates for openings not in use. They are UL listed raintight for thick-wall (rigid) conduit and concrete-tight for thin-wall (EMT) conduit.

| Conduit Trade Size | Pipe Size | Thread Type | Gender | Features | Includes | Specifications Met | Each | |

Aluminum | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 1/2 | NPSM | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 00000 |

| 1/2 | 1/2 | NPSM | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 0000 |

| 3/4 | 3/4 | NPSM | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 0000 |

| 3/4 | 3/4 | NPSM | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 0000 |

| 1 | 1 | NPSM | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 | 1 | NPSM | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/4 | 1 1/4 | NPSM | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/4 | 1 1/4 | NPSM | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/2 | 1 1/2 | NPSM | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/2 | 1 1/2 | NPSM | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 00000 |

| 2 | 2 | NPSM | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 00000 |

| 2 | 2 | NPSM | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 00000 |

Zinc-Plated Iron | ||||||||

| 1/2 | 1/2 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 00000 |

| 3/4 | 3/4 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 | 1 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/2 | 1 1/2 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 00000 |

| 2 | 2 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed, CSA Certified | 0000000 | 000000 |

316 Stainless Steel | ||||||||

| 1/2 | 1/2 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed | 0000000 | 000000 |

| 3/4 | 3/4 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed | 0000000 | 000000 |

| 1 | 1 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed | 0000000 | 000000 |

| 1 1/4 | 1 1/4 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed | 0000000 | 000000 |

| 1 1/2 | 1 1/2 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed | 0000000 | 000000 |

| 2 | 2 | NPT | Female | Removable Cover with Rubber Gasket | __ | UL Listed | 0000000 | 000000 |

| Conduit Trade Size | Pipe Size | Thread Type | Gender | Features | Includes | Specifications Met | Each | |

Aluminum | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 1/2 | NPT | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 000000 |

| 3/4 | 3/4 | NPT | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 | 1 | NPT | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/4 | 1 1/4 | NPT | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/2 | 1 1/2 | NPT | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 00000 |

| 2 | 2 | NPT | Female | Removable Cover with Rubber Gasket | Set Screw | UL Listed, CSA Certified | 0000000 | 000000 |

Access Ports for Rigid PVC Conduit

Also known as conduit bodies, these ports provide access to wire and cable inside PVC Schedule 40 or Schedule 80 conduit for pulling, splicing, and maintenance. They are also used to change the direction of a run. These ports are lightweight, corrosion resistant, and UV light resistant for outdoor use. They can be buried or encased in concrete. PVC cement is required (not included) to secure the connection.

Ports that can be configured as a straight, tee, or 90° elbow come with multiple cover plates for openings not in use.

Conduit Connection | ||||||||

|---|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Conduit Connection Type | Gender | Material | Color | Features | Specifications Met | Each | |

| 1/2 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 000000 |

| 3/4 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/4 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/2 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 00000 |

| 2 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 00000 |

Conduit Connection | ||||||||

|---|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Conduit Connection Type | Gender | Material | Color | Features | Specifications Met | Each | |

| 1/2 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 00000 |

| 3/4 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 0000 |

| 1 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/4 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 00000 |

| 1 1/2 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 00000 |

| 2 | Push-In | Female | PVC | Gray | Removable Cover | UL Listed, CSA Certified | 0000000 | 00000 |

Hazardous Location Conduit Access Ports

Also known as conduit bodies, these ports provide access to wire and cable inside thick-wall (rigid) metal conduit for pulling, splicing, and maintenance. They are also used to change the direction of a run. These ports meet Class I, II, and III; Divisions 1 and 2 standards for flammable gases, combustible dust, and combustible fibers in hazardous locations.

Conduit Connection | Tee (T) | |||||||

|---|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Pipe Size | Thread Type | Gender | Material | Features | Environmental Rating | Each | |

| 1/2 | 1/2 | NPT | Female | Aluminum | Removable Cover | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | 0000000 | 0000000 |

| 3/4 | 3/4 | NPT | Female | Aluminum | Removable Cover | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | 0000000 | 000000 |

| 1 | 1 | NPT | Female | Aluminum | Removable Cover | NEC Class I Divisions 1, 2 Group D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | 0000000 | 000000 |