How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

How to Measure Threaded Pipe Size

More

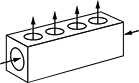

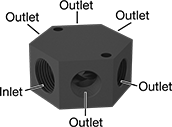

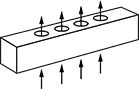

Right-Angle Flow Rectangular Manifolds

Distribute air or fluid to multiple locations from a single supply source with these manifolds. They are also known as headers. They have mounting holes, so you can mount from the top or side.

Aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. Anodized aluminum manifolds have a black finish and nickel-plated aluminum manifolds have a shiny finish.

Use a plug (sold separately) to close off any unused inlets and outlets.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: See table

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 1,000 psi @ 72° F

Hydraulic Fluid: See table - Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Thread Pitch, mm | Thread Size | Thread Pitch, mm | Lg., mm | Wd., mm | Ht., mm | Outlet Ctr.-to-Ctr., mm | Color | Maximum Pressure, Hydraulic Fluid | Temperature Range, °F | Each | |

Outlets on One Side—Standard Outlet Spacing | |||||||||||||

| 2 | M5 | 0.8 | M3 | 0.5 | 44 | 19 | 19 | 19 | Black | 3,000 psi @ 72° F | -65° to 250° | 00000000 | 000000 |

| 3 | M5 | 0.8 | M3 | 0.5 | 60 | 19 | 19 | 16 | Black | 3,000 psi @ 72° F | -65° to 250° | 00000000 | 00000 |

| 4 | M8 | 1.25 | M5 | 0.8 | 76 | 19 | 19 | 16 | Black | 3,000 psi @ 72° F | -65° to 250° | 00000000 | 00000 |

| 4 | M12 | 1.25 | M10 | 1.25 | 82 | 25 | 25 | 16 | Black | 1,000 psi @ 72° F | -10° to 200° | 0000000 | 00000 |

| 4 | M14 | 1.5 | M12 | 1.25 | 105 | 32 | 32 | 22 | Black | 1,000 psi @ 72° F | -10° to 200° | 0000000 | 00000 |

| 6 | M5 | 0.8 | M3 | 0.5 | 120 | 19 | 19 | 19 | Black | 3,000 psi @ 72° F | -65° to 250° | 00000000 | 00000 |

| 6 | M8 | 1.25 | M6 | 1 | 108 | 19 | 19 | 16 | Black | 3,000 psi @ 72° F | -65° to 250° | 00000000 | 00000 |

| Thread Size | Thread Pitch, mm | Drive | Pressure Class | Max. Pressure | Each | |

Aluminum—Metric | ||||||

|---|---|---|---|---|---|---|

| M3 | 0.5 | External Hex | 150 | 150 psi @ 72° F | 00000000 | 00000 |

| M5 | 0.8 | External Hex | __ | 1,000 psi @ 72° F | 00000000 | 0000 |

| M8 | 1.25 | External Hex | __ | 1,000 psi @ 72° F | 00000000 | 0000 |

| M10 | 1.25 | External Hex | 150 | 150 psi @ 72° F | 00000000 | 0000 |

| M12 | 1.25 | External Hex | 150 | 150 psi @ 72° F | 00000000 | 0000 |

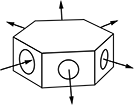

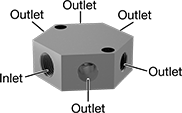

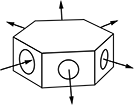

Low-Profile Hex Manifolds

When you’re short on vertical space, these manifolds are a good fit—they have outlets on the side instead of on top, so they have a lower profile than rectangular manifolds. Use them to distribute air, water, or hydraulic fluid to five locations from a single supply source. Manifolds have mounting holes, so you can mount from the top.

Anodized aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. These manifolds are anodized for a black finish.

316 stainless steel manifolds have excellent corrosion resistance and can handle fuel, gasoline, coolant and other harsh substances.

Use a plug (sold separately) to close off any unused inlets and outlets.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure: 1,000 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Thread Pitch, mm | Thread Size | Thread Pitch, mm | Wd., mm | Ht., mm | Outlet Spacing | Color | Each | |

| 5 | M6 | 1 | M3 | 0.5 | 45 | 13 | Standard | Black | 00000000 | 000000 |

| 5 | M8 | 1 | M6 | 1 | 45 | 19 | Standard | Black | 00000000 | 00000 |

| 5 | M10 | 1 | M8 | 1 | 38.1 | 19 | Standard | Black | 00000000 | 00000 |

| 5 | M12 | 1.5 | M10 | 1 | 47 | 25 | Standard | Black | 00000000 | 00000 |

| 5 | M14 | 1.5 | M12 | 1.5 | 47 | 25 | Standard | Black | 00000000 | 000000 |

| 5 | M16 | 1.5 | M14 | 1.5 | 47 | 25 | Standard | Black | 00000000 | 000000 |

| 5 | M20 | 1.5 | M18 | 1.5 | 50 | 31 | Standard | Black | 00000000 | 000000 |

| 5 | M22 | 1.5 | M20 | 1.5 | 50 | 38 | Standard | Black | 00000000 | 000000 |

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Thread Pitch, mm | Thread Size | Thread Pitch, mm | Wd., mm | Ht., mm | Outlet Spacing | Each | |

| 5 | M6 | 1 | M3 | 0.5 | 45 | 13 | Standard | 00000000 | 0000000 |

| 5 | M8 | 1 | M6 | 1 | 45 | 19 | Standard | 00000000 | 000000 |

| 5 | M10 | 1 | M8 | 1 | 45 | 19 | Standard | 00000000 | 000000 |

| 5 | M12 | 1.5 | M10 | 1 | 47 | 25 | Standard | 00000000 | 000000 |

| 5 | M14 | 1.5 | M12 | 1.5 | 47 | 25 | Standard | 00000000 | 000000 |

| 5 | M16 | 1.5 | M14 | 1.5 | 47 | 25 | Standard | 00000000 | 000000 |

| 5 | M20 | 1.5 | M18 | 1.5 | 50 | 31 | Standard | 00000000 | 000000 |

| 5 | M22 | 1.5 | M20 | 1.5 | 50 | 38 | Standard | 00000000 | 000000 |

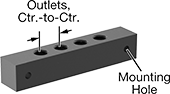

Straight-Flow Junction Blocks

Use these junction blocks to organize and separate multiple lines in your system. They have threaded holes that allow air, water, or hydraulic fluid to flow straight through the block. They have mounting holes, so you can mount from the side.

Anodized aluminum junction blocks are lightweight with good corrosion and wear resistance.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure:

Air: 1,000 psi @ 72° F

Water: 1,000 psi @ 72° F

Hydraulic Fluid: 3,000 psi @ 72° F - Maximum Vacuum: Not Rated

Shatter-Resistant Sights

The window and body are made from a single piece of plastic, making these sights more shatter resistant than sights with a glass window. They are not rated for pressure.

Temp. Range, °F | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Window Dia. | Hex Size | Max. Pressure | Min. | Max. | For Use With | Window Material | Seal Material | Each | |

Plastic | ||||||||||

Metric Male Thread | ||||||||||

| M16 × 1.5 mm | 7/16" | 3/4" | Not Rated | -20° | 210° | Water, Diesel Fuel, Hydraulic Fluid (Petroleum Based) | Plastic | Buna-N Rubber | 00000000 | 00000 |

| M20 × 1.5 mm | 9/16" | 7/8" | Not Rated | -20° | 210° | Water, Diesel Fuel, Hydraulic Fluid (Petroleum Based) | Plastic | Buna-N Rubber | 00000000 | 0000 |

| M25 × 1.5 mm | 11/16" | 1 1/16" | Not Rated | -20° | 210° | Water, Diesel Fuel, Hydraulic Fluid (Petroleum Based) | Plastic | Buna-N Rubber | 00000000 | 0000 |

| M27 × 1.5 mm | 13/16" | 1 1/16" | Not Rated | -20° | 210° | Water, Diesel Fuel, Hydraulic Fluid (Petroleum Based) | Plastic | Buna-N Rubber | 00000000 | 0000 |

| M30 × 1.5 mm | 7/8" | 1 3/16" | Not Rated | -20° | 210° | Water, Diesel Fuel, Hydraulic Fluid (Petroleum Based) | Plastic | Buna-N Rubber | 00000000 | 0000 |

| M40 × 1.5 mm | 1 3/16" | 1 5/8" | Not Rated | -20° | 210° | Water, Diesel Fuel, Hydraulic Fluid (Petroleum Based) | Plastic | Buna-N Rubber | 00000000 | 00000 |

Pressure Test Fittings

Check pressure without permanently installing a gauge. Fittings have an NPT male connection for installation in your pipe or tank. Wrench-tighten the fitting onto your equipment, then insert the gauge adapter (sold separately) into the fitting. Connect gauge adapters to gauges with 1/4 pipe size NPT male threads.

Plugs | Gauge Adapters | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Size | Thread Pitch, mm | Max. Pressure, psi | Gasket Material | Ht. | For Use With | Each | Each | ||

NPT Male × Metric Male | ||||||||||

Steel | ||||||||||

| 1/8 | M16 | 2 | 5,800 | Fluoroelastomer Rubber | 1 1/2" | Air, Argon, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydraulic Fluid (Petroleum Based), Natural Gas, Nitrogen, Water | 0000000 | 000000 | 0000000 | 000000 |

| 1/4 | M16 | 2 | 5,800 | Fluoroelastomer Rubber | 1 1/2" | Air, Argon, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydraulic Fluid (Petroleum Based), Natural Gas, Nitrogen, Water | 0000000 | 00000 | 0000000 | 00000 |