Filter by

Consistency

For Use On

Maximum Temperature

Container Size

Hardness Rating

Thermal Conductivity

Dielectric Strength

Touch Dry Time

Hardness

Tensile Strength

DFARS Specialty Metals

Material

Epoxy Potting Compounds

3M Potting Compounds—Extra Hard

Dry Time | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch | Overall | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Temp. Range, ° F | Flammability Rating | For Use On | Choose a Color | Each | ||

| DP270 | 1.64 | Thick Liquid | 3 hr. | 48 hr. | 850 | 0.18 | -65 to 210 | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Glass | Black , Clear | 00000000 | 000000 | |

| DP270 | 6.8 | Thick Liquid | 3 hr. | 48 hr. | 850 | 0.18 | -65 to 210 | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Glass | Black , Clear | 00000000 | 00000 | |

| DP270 | 13.5 | Thick Liquid | 3 hr. | 48 hr. | 850 | 0.18 | -65 to 210 | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Glass | Black | 00000000 | 000000 | |

| DP460EG | 1.69 | Thick Liquid | 110 min. | 7 day | 510 | Not Rated | 0 to 175 | — | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic | Off-White | 00000000 | 00000 | |

Loctite® Potting Compounds—Extra Hard

Dry Time | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hr. | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Temp. Range, ° F | Flammability Rating | For Use On | Color | Each | ||

| E-60NC | 1.7 | Thick Liquid | 60 | 24 | 550 | Not Rated | -65 to 250 | — | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Fiberglass | Black | 0000000 | 000000 | |

| E-60NC | 6.8 | Thick Liquid | 60 | 24 | 550 | Not Rated | -65 to 250 | — | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Fiberglass | Black | 0000000 | 00000 | |

| E-60NC | 13.5 | Thick Liquid | 60 | 24 | 550 | Not Rated | -65 to 250 | — | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Fiberglass | Black | 0000000 | 00000 | |

| ES1001 | 1.7 | Thick Liquid | 60 | 24 | 1,100 | 0.29 | -10 to 220 | — | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 00000 | |

| ES1902 | 1.7 | Thin Liquid | 60 | 24 | 1,350 | Not Rated | -40 to 250 | — | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic | Clear | 0000000 | 00000 | |

| ES2500 | 1.7 | Thin Liquid | 10 | 16 | 410 | 0.28 | -40 to 220 | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Black | 0000000 | 00000 | |

Potting Compounds—Extra Hard

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, fl. oz. | Consistency | Touch, min. | Overall, hr. | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Temp. Range, ° F | For Use On | Color | Cannot Be Sold To | Each | ||

| 1.69 | Thick Liquid | 45 | 24 | 400 | 0.3 | -40 to 300 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Plastic, Rubber, Composite, Fiberglass, Ceramic, Glass | Black | Canada | 0000000 | 000000 | |

Heat-Transfer Epoxy Potting Compounds

Jar and Syringe Potting Compounds—Extra Hard

Dry Time | Temp. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, fl. oz. | Consistency | Touch | Overall, hr. | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Min. | Max., ° F | Heating Req. to Reach Full Strength | For Use On | Color | Each | ||

| 0.9 | Thick Liquid | 25 min. | 24 | 450 | 1.87 | Not Rated | 500 | 1 hr. @ 250°F Then 1 hr. @ 350°F | Aluminum, Brass, Bronze, Cast Iron, Copper, Iron, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Ceramic, Glass | Black | 0000000 | 000000 | |

| 1 | Gel | 4 hr. | 6 | Not Rated | 1.87 | Not Rated | 600 | 4 Hrs. @ 250°F Then 2 Hrs. @ 350°F | Aluminum, Brass, Bronze, Cast Iron, Copper, Iron, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Ceramic, Glass | Black | 0000000 | 00000 | |

| 1.5 | Thin Liquid | 30 min. | 26 | 450 | 0.21 | Not Rated | 500 | 1 hr. @ 250°F Then 1 hr. @ 350°F | Aluminum, Brass, Bronze, Cast Iron, Copper, Iron, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Ceramic, Glass | Amber | 0000000 | 00000 | |

Pail and Bottle Potting Compounds—Extra Hard

Dry Time | Temp. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, gal. | Consistency | Touch, min. | Overall, hr. | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Min. | Max., ° F | For Use On | Color | Each | ||

| 1 | Thick Liquid | 25 | 24 | 450 | 1.87 | Not Rated | 500 | Steel, Ceramic, Glass | Black | 0000000 | 0000000 | |

Cartridge Potting Compounds—Extra Hard

Dry Time | Temp., ° F | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, fl. oz. | Consistency | Touch, min. | Overall, hr. | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Min. | Max. | For Use On | Color | Each | ||

| 1.7 | Thick Liquid | 15 | 8 | 520 | 1.01 | -40 | 210 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Fiberglass | Black | 0000000 | 000000 | |

Jar and Bottle Potting Compounds—Extra Hard

Dry Time | Temp. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, fl. oz. | Consistency | Touch | Overall, hr. | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Min. | Max., ° F | Heating Req. to Reach Full Strength | For Use On | Color | Each | ||

| 16 | Thin Liquid | 30 min. | 26 | 450 | 0.21 | Not Rated | 500 | 1 hr. @ 250°F Then 1 hr. @ 350°F | Aluminum, Brass, Bronze, Cast Iron, Copper, Iron, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Ceramic, Glass | Amber | 0000000 | 0000000 | |

| 19 | Thick Liquid | 25 min. | 24 | 450 | 1.87 | Not Rated | 500 | — | Steel, Ceramic, Glass | Black | 0000000 | 000000 | |

| 20 | Gel | 4 hr. | 6 | Not Rated | 1.87 | Not Rated | 600 | 4 Hrs. @ 250°F Then 2 Hrs. @ 350°F | Steel, Ceramic, Glass | Black | 0000000 | 000000 | |

Adjustable-Hardness Heat-Transfer Epoxy Potting Compounds

Dry Time | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, fl. oz. | Consistency | Touch, min. | Overall, hr. | Hardness Rating | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Temp. Range, ° F | Heating Req. to Reach Full Strength | For Use On | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Jars | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | Thick Liquid | 30 | 24 | Extra Hard, Medium Hard, Medium Soft, Soft | 450 | 1 | -100 to 450 | — | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Tan | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | Thick Liquid | 30 | 24 | Extra Hard, Medium Hard, Medium Soft, Soft | 450 | 1 | -100 to 450 | — | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Tan | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Jars and Syringes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 | Thick Liquid | 30 | 26 | Extra Hard, Medium Hard, Medium Soft, Soft | 450 | 1.01 | -100 to 450 | 2 Hrs. @ 250°F | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Tan | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Epoxy Potting Compounds

Dry Time | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, fl. oz. | Consistency | Viscosity, cP | Touch | Overall, hr. | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Max. Temp., ° F | For Use On | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Jar and Syringe Potting Compounds—Extra Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Thick Liquid | 3,600 | 12 hr. | 24 | 450 | 0.22 | 500 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Composite, Fiberglass, Ceramic, Glass | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bottle Potting Compounds—Extra Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12.6 | Paste | 22,000 | 60 min. | 24 | 470 | 0.3 | 435 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Composite, Fiberglass, Ceramic, Glass | Canada | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy Duty Coatings for Electronics

Dry Time | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hr. | Mixer Nozzle Included | Mix Ratio | Dielectric Strength, V/mil | Thermal Conductivity | Temp. Range, ° F | Certificate Type | For Use On | Color | Clarity | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Loctite® Cartridge Potting Compounds—Extra Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E-00CL | 1.7 | Thick Liquid | 5 | 24 | No | 1:1 | 400 | Not Rated | -65 to 180 | Material Certificate with Traceable Lot Number and Product Shelf Life | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Fiberglass | Clear | Clear | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E-00CL | 6.8 | Thick Liquid | 5 | 24 | No | 1:1 | 400 | Not Rated | -65 to 180 | Material Certificate with Traceable Lot Number and Product Shelf Life | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Fiberglass | Clear | Clear | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flexible Epoxy Potting Compounds

Dry Time, hr. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, fl. oz. | Consistency | Touch | Overall | Mixer Nozzle Included | Mix Ratio | Dielectric Strength | Thermal Conductivity | Temp. Range, ° F | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cartridge Potting Compounds—Soft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | Thick Liquid | 24 | 72 | No | 1:1 | Not Rated | Not Rated | -85 to 275 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Plastic, Rubber, Composite, Fiberglass, Ceramic, Glass | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Optically Clear Epoxy Potting Compounds

Dry Time | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hr. | Mixer Nozzle Included | Mix Ratio | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Temp. Range, ° F | For Use On | Color | Clarity | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Loctite® Cartridge Potting Compounds—Extra Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ES1901 | 1.7 | Thick Liquid | 3 | 24 | Yes | 1:1 | 400 | Not Rated | -40 to 220 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Clear | Clear | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cartridge Potting Compounds—Extra Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1.7 | Thick Liquid | 40 | 24 | No | 1:1 | 500 | 0.24 | -65 to 275 | Aluminum, Brass, Bronze, Cast Iron, Copper, Iron, Steel, Stainless Steel, Silver, Plastic, Rubber, Composite, Fiberglass, Ceramic, Glass | Amber | Clear | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flame-Retardant Epoxy Potting Compounds

Dry Time, hr. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size | Consistency | Touch | Overall | Mixer Nozzle Included | Mix Ratio | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Temp. Range, ° F | Flammability Rating | For Use On | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cartridge Potting Compounds—Extra Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15.2 fl. oz. | Thick Liquid | 2 | 48 | Yes | 2:1 | 395 | 0.5 | -110 to 390 | UL 94 V-0 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Plastic, Rubber, Composite, Fiberglass, Ceramic, Glass | Canada | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Can Potting Compounds—Extra Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 qt. | Thick Liquid | 2 | 48 | — | 2:1 | 395 | 0.5 | -110 to 390 | UL 94 V-0 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Plastic, Rubber, Composite, Fiberglass, Ceramic, Glass | Canada | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Epoxy Potting Compounds for Harsh Environments

Dry Time, hr. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, fl. oz. | Consistency | Touch | Overall | Mixer Nozzle Included | Mix Ratio | Dielectric Strength, V/mil | Thermal Conductivity | Temp. Range, ° F | Environment | For Use On | Autoclavable | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cartridge Potting Compounds—Extra Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.69 | Thick Liquid | 12 | 24 | No | 2:1 | 500 | Not Rated | -50 to 350 | Corrosive, Harsh, Submersible | Brass, Bronze, Cast Iron, Copper, Steel, Stainless Steel, Titanium, Polycarbonate, Polyurethane Rubber, Glass, ABS, CPVC, HDPE, Nylon, PEEK, Polyethylene, Polyimide, Polypropylene, Polystyrene, PVC, PVDF, UHMW Polyethylene | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Light-Activated Epoxy Potting Compounds

Dry Time | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hr. | Mixer Nozzle Included | Mix Ratio | Light Intensity Req. to Reach Full Strength | Cure Type | Dielectric Strength | Thermal Conductivity | Temp. Range, ° F | For Use On | Color | Clarity | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Loctite® Cartridge Potting Compounds—Extra Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3336 | 1.4 | Thick Liquid | 5 | 16 | No | 4:1 | 60 sec. @ 30 mW/cm² | UV Light | Not Rated | Not Rated | -65 to 350 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Silver, Titanium, Plastic, Composite, Fiberglass | Amber | Clear | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Outgassing Heat-Transfer Epoxy Potting Compounds

Dry Time | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, fl. oz. | Consistency | Touch | Overall, hr. | Mix Ratio | Dielectric Strength, V/mil | Thermal Conductivity, W/(m⋅°C) | Temp. Range, ° F | Heating Req. to Reach Full Strength | Specs. Met | For Use On | Color | Clarity | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pail and Can Potting Compounds—Extra Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | Thick Liquid | 45 min. | 24 | 100:8.5 | 365 | 1.25 | -40 to 265 | — | ASTM E595 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic | Black | Opaque | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | Thick Liquid | 4 hr. | 12 | 100:14 | 450 | 0.55 | -65 to 310 | 12 Hrs. @ 175°F | ASTM E595 | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic | Black | Opaque | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

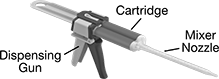

Mixer Nozzles for Two-Part Adhesive Cartridges

Bell-Mount Fitting Connection

|

Bell-Mount Fitting Connection |

For Cartridge Size, fl. oz. | Mix Ratio | Opening ID | Lg. | No. of Mixing Elements | Mfr. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

5-Step Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.76, 13.5 | 1:1, 2:1 | 0.66" | 5" | 20 | 3M | Polypropylene | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||