About Pressure Transmitters

More

About Selecting Temperature Sensors

More

Food and Beverage Threaded Thermometers

Dry dials with plastic lenses eliminate the risk of contamination in case of breakage, so these thermometers are often used in food-processing applications.

For technical drawings and 3-D models, click on a part number.

Available Temperature Ranges | ||

|---|---|---|

| Temperature Range | Graduation Marks | Accuracy |

| -40° to 120° F | 2° F | ±1% |

| 0° to 200° F | 2° F | ±1% |

| 0° to 250° F | 2° F | ±1% |

| 50° to 300° F | 2° F | ±1% |

| 50° to 550° F | 5° F | ±1% |

| 0° to 100° C | 1° C | ±1% |

| 0° to 150° C | 1° C | ±1% |

Stem | Material | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Dia. | Dial Dia. | Pipe Size | Thread Type | Gender | Max. Pressure | Overall Ht. | Housing | Stem | Lens | Each | |

Back Connection | ||||||||||||

| 2 1/2" | 1/4" | 3" | 1/2 | NPT | Male | Not Rated | 4 1/8" | Stainless Steel | Stainless Steel | Polycarbonate | 00000000 | 000000 |

| 2 1/2" | 1/4" | 5" | 1/2 | NPT | Male | Not Rated | 4 1/8" | Stainless Steel | Stainless Steel | Polycarbonate | 00000000 | 000000 |

| 4" | 1/4" | 3" | 1/2 | NPT | Male | Not Rated | 5 5/8" | Stainless Steel | Stainless Steel | Polycarbonate | 00000000 | 00000 |

| 4" | 1/4" | 5" | 1/2 | NPT | Male | Not Rated | 5 5/8" | Stainless Steel | Stainless Steel | Polycarbonate | 00000000 | 000000 |

| 6" | 1/4" | 3" | 1/2 | NPT | Male | Not Rated | 7 5/8" | Stainless Steel | Stainless Steel | Polycarbonate | 00000000 | 00000 |

| 6" | 1/4" | 5" | 1/2 | NPT | Male | Not Rated | 7 5/8" | Stainless Steel | Stainless Steel | Polycarbonate | 00000000 | 000000 |

Food and Beverage Thermometers with Sanitary Quick-Clamp Connection

For dairy, food, and beverage applications that require frequent cleaning, these 3-A certified thermometers have a sanitary quick-clamp connection for easy removal.

For technical drawings and 3-D models, click on a part number.

Available Temperature Ranges | ||

|---|---|---|

| Temperature Range | Graduation Marks | Accuracy |

| -40° to 120° F | 1° F | ±1% |

| 0° to 200° F | 2° F | ±1% |

| 0° to 250° F | 2° F | ±1% |

| 50° to 300° F | 2° F | ±1% |

| 0° to 100° C | 1° C | ±1% |

| 0° to 150° C | 1° C | ±1% |

Stem | Material | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Dia. | Dial Dia. | For Tube OD | Flange OD | Housing | Stem | Lens | Flange | Specifications Met | Each | |

Back Connection | |||||||||||

| 2 1/2" | 5/16" | 3" | 1 1/2" | 1.984" | Stainless Steel | Stainless Steel | Acrylic | Stainless Steel | 3-A Certified 74-07 | 00000000 | 0000000 |

| 2 1/2" | 5/16" | 3" | 2" | 2.516" | Stainless Steel | Stainless Steel | Acrylic | Stainless Steel | 3-A Certified 74-07 | 00000000 | 000000 |

| 2 1/2" | 5/16" | 5" | 1 1/2" | 1.984" | Stainless Steel | Stainless Steel | Acrylic | Stainless Steel | 3-A Certified 74-07 | 00000000 | 000000 |

| 2 1/2" | 5/16" | 5" | 2" | 2.516" | Stainless Steel | Stainless Steel | Acrylic | Stainless Steel | 3-A Certified 74-07 | 00000000 | 000000 |

| 4 1/2" | 5/16" | 3" | 1 1/2" | 1.984" | Stainless Steel | Stainless Steel | Acrylic | Stainless Steel | 3-A Certified 74-07 | 00000000 | 000000 |

| 4 1/2" | 5/16" | 3" | 2" | 2.516" | Stainless Steel | Stainless Steel | Acrylic | Stainless Steel | 3-A Certified 74-07 | 00000000 | 000000 |

| 4 1/2" | 5/16" | 5" | 1 1/2" | 1.984" | Stainless Steel | Stainless Steel | Acrylic | Stainless Steel | 3-A Certified 74-07 | 00000000 | 000000 |

| 4 1/2" | 5/16" | 5" | 2" | 2.516" | Stainless Steel | Stainless Steel | Acrylic | Stainless Steel | 3-A Certified 74-07 | 00000000 | 000000 |

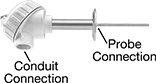

Sanitary RTD Probes for Liquids and Gases

Designed for clean-in-place applications such as dairy processing and food-preparation areas, these 3-A certified RTDs have a sanitary quick-clamp connection for easy removal. Remove the cap on the head to wire the probe’s terminal block to your application.

For technical drawings and 3-D models, click on a part number.

Probe | Conduit Connection | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RTD Type | Temperature Range, °F | Lg. | Dia. | Flange OD | Accuracy | Response Time, sec. | Connection Type | Pipe Size | Thread Type | Gender | Overall Lg. | Each | |

316 Stainless Steel Probe with Plastic Head | |||||||||||||

For 1 1/2" Tube OD | |||||||||||||

| 100 ohms | -325° to 400° | 4" | 1/4" | 1.984" | ±0.1% | 5 | Screw Terminal | 3/4 | NPT | Female | 11" | 0000000 | 0000000 |

For 2" Tube OD | |||||||||||||

| 100 ohms | -325° to 400° | 4" | 1/4" | 2.516" | ±0.1% | 5 | Screw Terminal | 3/4 | NPT | Female | 11" | 0000000 | 000000 |

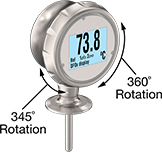

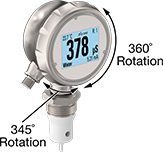

Sanitary RTD Probe Transmitters with Digital Display for Liquids and Gases

Check the temperature of liquids in hygienic applications such as food or pharmaceutical lines and tanks. Certified by 3-A to meet sanitary design standards, the parts of these probes that will touch liquid are highly polished to minimize spots where bacteria could grow. They're made of stainless steel, so they won't corrode from harsh cleaners and sanitizers. The housing is IP69K rated, meaning it withstands high-pressure, high-temperature washdowns that are common in hygienic cleaning practices. They have a flange that will connect to sanitary quick-clamp fittings (also known as tri-clamp fittings); they're easy to connect and remove from your line.

Program these probes with the touch screen, and select one of three colors as a visual alert for events in your process such as irregular or fluctuating temperatures. The head swivels 345° and the face rotates all the way around, so you can mount the sensor at any angle and still see the display. To trigger actions in your process line, connect these probes to remote displays, programmable logic controllers (PLCs), and other control equipment with the M12 plug. These probes meet DIN EN 60751, an industry standard for accuracy. They’re also CE marked, meaning they meet European Union safety standards.

For technical drawings and 3-D models, click on a part number.

Probe | Probe Transmitters | Cables with Socket | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RTD Type | Temperature Range, °F | Lg. | Dia. | Flange OD | Accuracy | Response Time, sec. | Plug Type | DC Voltage | Max. Pressure, psi | Output Current | Overall Lg. | Each | Each | ||

316L Stainless Steel Probe with 304 Stainless Steel Head (IP69K) | |||||||||||||||

For 1 1/2" Tube OD | |||||||||||||||

| 100 ohms | -55° to 480° | 2" | 5/16" | 1.988" | ±0.1% | 25 | 5-Pole Micro M12 | 8-35 | 580 | 4-20mA | 6 3/4" | 0000000 | 0000000 | 0000000 | 000000 |

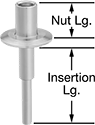

Food and Beverage Thermowells with Sanitary Quick-Clamp Connection

Isolate thermometers and temperature probes from the contents of dairy and food-processing equipment with these 3-A certified thermowells that have a sanitary quick-clamp connection for easy removal. They require a quick-clamp fitting (not included) for installation.

For technical drawings and 3-D models, click on a part number.

For Thermometer | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Stem Lg. | Stem Dia. | Connection Pipe Size | Connection Thread Type | Connection Gender | Nut Lg. | Insertion Lg. | Flange OD | Specifications Met | Each | |

316 Stainless Steel | |||||||||||

| 1", 1 1/2" | 2 1/2" | 1/4" | 1/2 | NPT | Male | 1 1/16" | 1 5/8" | 1.984" | 3-A Certified 74-06 | 0000000 | 0000000 |

| 1", 1 1/2" | 4" | 1/4" | 1/2 | NPT | Male | 1 3/4" | 2 1/2" | 1.984" | 3-A Certified 74-06 | 0000000 | 000000 |

| 1", 1 1/2" | 6" | 1/4" | 1/2 | NPT | Male | 1 3/4" | 4 1/2" | 1.984" | 3-A Certified 74-06 | 0000000 | 000000 |

| 1", 1 1/2" | 9" | 1/4" | 1/2 | NPT | Male | 1 3/4" | 7 1/2" | 1.984" | 3-A Certified 74-06 | 0000000 | 000000 |

| 2" | 2 1/2" | 1/4" | 1/2 | NPT | Male | 1 1/16" | 1 5/8" | 2.516" | 3-A Certified 74-06 | 0000000 | 000000 |

| 2" | 4" | 1/4" | 1/2 | NPT | Male | 1 3/4" | 2 1/2" | 2.516" | 3-A Certified 74-06 | 0000000 | 000000 |

| 2" | 6" | 1/4" | 1/2 | NPT | Male | 1 3/4" | 4 1/2" | 2.516" | 3-A Certified 74-06 | 0000000 | 000000 |

| 2" | 9" | 1/4" | 1/2 | NPT | Male | 1 3/4" | 7 1/2" | 2.516" | 3-A Certified 74-06 | 0000000 | 000000 |

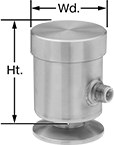

Sanitary Pressure Transmitters

- For Use With: Air, Argon, Diesel Fuel, Gasoline, Hydraulic Fluid, Nitrogen, Water

- Accuracy: ±0.5%

- Housing Material: 304 Stainless Steel

- Connection Material: 316 Stainless Steel

- Temperature Range: 30° to 300° F

For use in sanitary applications such as food processing, these transmitters are 3-A certified. They are rated IP66, IP69K, and NEMA 4X to resist washdowns and corrosion. Also known as transducers, they convert pressure to an electrical signal that can be interpreted by receiving devices, such as remote displays, programmable logic controllers, and motor speed controls to monitor pressure or control equipment. As pressure increases, the output signal from the transmitter will increase. For your receiving device to interpret the signal from the transmitter, you will need to calibrate it for the transmitter's pressure range and output signal. Transmitters are accurate only within the pressure range.

These transmitters connect using two wires to send a 4-20mA current output. The same wire is used to send a signal to the receiver and to power the transmitter. Current doesn’t lose signal over long distances and isn’t affected by electrical interference from other devices. Transmitters are compatible with micro M12 sockets.

For technical drawings and 3-D models, click on a part number.

| Pressure Range, psi | Maximum Continuous Pressure, psi | Maximum Short-Term Pressure, psi | Input Voltage | Ht. | Wd. | Environmental Rating | Specifications Met | Each | |

For 1 1/2" Flange OD | |||||||||

|---|---|---|---|---|---|---|---|---|---|

4-20mA Current Output—5-Pole Micro M12 Plug Connection | |||||||||

| 0-15 | 15 | 30 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 0000000 |

| 0-50 | 50 | 100 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-100 | 100 | 200 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-200 | 200 | 400 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-500 | 500 | 1,000 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

For 2" Flange OD | |||||||||

4-20mA Current Output—5-Pole Micro M12 Plug Connection | |||||||||

| 0-15 | 15 | 30 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-50 | 50 | 100 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-100 | 100 | 200 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-200 | 200 | 400 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-500 | 500 | 1,000 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

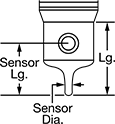

Sanitary Conductivity Sensors

Often used to save rinse water in beverage and pharmaceutical lines, these sensors test the amount of chemicals, cleaners, and other substances in liquids by measuring how well the liquid conducts electricity. They’re 3-A and European Hygienic Engineering and Design Group (EHEDG) certified, thanks to their design that’s easy to keep clean. Highly polished, they limit where bacteria could grow. They also withstand washdowns with hot water, chemicals, and cleaners common to sanitary lines because of their PEEK probe, stainless steel body, and IP ratings. Their IP ratings also mean they’re dust tight and won’t fail if briefly under water. All are FDA compliant to safely touch food.

These sensors work with 4-20 mA analog output to connect to remote displays and programmable logic controllers (PLCs), making them good for hard-to-reach areas and frequent application changes. This also means they’ll set off alarms and trigger cycles to start and stop in automated systems. With the touchscreen, program each color of the display to alert you to errors, completed cycles, and other events. Both the head and the display rotate to view readings from the best angle.

Highly accurate, these sensors test almost any liquid. They also measure temperature—no need for a separate sensor. To compare readings as temperature changes, they automatically standardize readings at 77° F. All meet European safety standards, since they’re CE marked.

Use quick-clamp adapters to connect these sensors to quick-clamp sanitary tube fittings.

Import regulations restrict sales to the listed areas.

For technical drawings and 3-D models, click on a part number.

Sensor | Conductivity | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg., mm | Material | Dia., mm | Lg., mm | Range | Accuracy | Electrical Connection Type | Pipe Size | Thread Type | Gender | Automatic Temp. Compensation (ATC) Range, °F | Environmental Rating | Specifications Met | Each | |

For Use With Liquids | ||||||||||||||

| 37 | PEEK Plastic | 3.6 | 26 | 0 to 1,000 mS 0 to 500 mS 0 to 500 µS | ±1.5% ±1% ±1.5% | Threaded M12 Plug (Two 4-Pole Connections) | 1 | BSPP | Male | -4° to 302° | IP67, IP69K | 3-A Certified 74-07, CE Marked, EHEDG Certified, FDA Compliant 21 CFR 177.2415 | 0000000 | 000000000 |

| 60 | PEEK Plastic | 3.6 | 26 | 0 to 1,000 mS 0 to 500 mS 0 to 500 µS | ±1.5% ±1% ±1.5% | Threaded M12 Plug (Two 4-Pole Connections) | 1 | BSPP | Male | -4° to 302° | IP67, IP69K | 3-A Certified 74-07, CE Marked, EHEDG Certified, FDA Compliant 21 CFR 177.2415 | 0000000 | 00000000 |

| Optional Quick-Clamp Adapter | 0000000 | Each | 0000000 |