3J Collets

When installed into a 3J collet chuck or holder, these collets securely grip round workpieces. They provide a stronger hold on small workpieces than a standard lathe chuck. All have external threads.

| Collet Size | TIR (Total Indicated Runout) Accuracy | Workpiece Dia. Tolerance | Body Dia. | Overall Lg. | External Thread Size | Material | Each | |

Round | ||||||||

|---|---|---|---|---|---|---|---|---|

| 3/8" | 0.0008" | -0.004" to 0" | 2" | 3 3/4" | 1.988"-20 | Steel | 00000000 | 000000 |

| 1/2" | 0.0011" | -0.004" to 0" | 2" | 3 3/4" | 1.988"-20 | Steel | 00000000 | 00000 |

| 5/8" | 0.0011" | -0.004" to 0" | 2" | 3 3/4" | 1.988"-20 | Steel | 00000000 | 00000 |

| 3/4" | 0.0015" | -0.004" to 0" | 2" | 3 3/4" | 1.988"-20 | Steel | 00000000 | 00000 |

| 7/8" | 0.0015" | -0.004" to 0" | 2" | 3 3/4" | 1.988"-20 | Steel | 00000000 | 00000 |

| 1" | 0.0015" | -0.004" to 0" | 2" | 3 3/4" | 1.988"-20 | Steel | 00000000 | 00000 |

| 1 1/8" | 0.0015" | -0.004" to 0" | 2" | 3 3/4" | 1.988"-20 | Steel | 00000000 | 00000 |

| 1 1/4" | 0.0015" | -0.004" to 0" | 2" | 3 3/4" | 1.988"-20 | Steel | 00000000 | 00000 |

| 1 1/2" | 0.0015" | -0.004" to 0" | 2" | 3 3/4" | 1.988"-20 | Steel | 00000000 | 00000 |

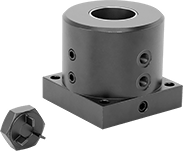

Machine-Your-Own 3J Collets

When installed into a 3J collet chuck or holder, these collets can securely grip workpieces. Also known as emergency collets, their machinable face allows you to bore an opening to exactly the size and shape you need. All have external threads.

| Max. Bore Dia. | Body Dia. | Overall Lg. | Face Pilot Hole Dia. | External Thread Size | Material | Each | |

| 1 3/4" | 2" | 3 3/4" | 1/16" | 1.988"-20 | Hardened Steel | 00000000 | 0000000 |

Collet Fixtures

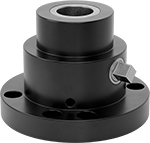

Pair these fixtures with collets to tightly grip workpieces for machining. You can mount them on milling machines, drill presses, and other work surfaces. However, they’re not for use with lathes, grinders, or high-speed rotary tables. All have a through hole to accommodate long workpieces.

Square-drive fixtures are designed for precise, repeatable workholding with consistent clamping force. They keep the collet stationary while their sleeve clamps. Made of steel, these fixtures are stronger and more wear resistant than cast iron fixtures, and they can hold up to higher clamping forces. They’re precision machined for accuracy. Use the included socket wrench to clamp and unclamp your workpiece or use a calibrated torque wrench to fine-tune the clamping force.

Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Collet Type | For Max. Workpiece Dia. | Through Hole Dia. | Dia. | Ht. | Material | No. of | Dia. | Bolt Circle Dia. | Mounting Orientation | Power Source | Includes | Each | |

| 3J | 1 3/4" | 1 15/16" | 5" | 4" | Black-Oxide Steel | 6 | 3/8" | 4 1/8" | Horizontal, Vertical | Manual | Socket Wrench | 0000000 | 000000000 |

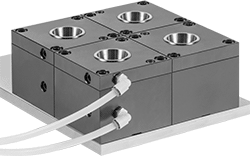

High-Density Air/Hydraulic-Operated Collet Fixtures

Push a button to clamp or release multiple workpieces on your milling machine or drill press. To create a high-density setup, mount these fixtures and join them together using two connector bushings (sold separately) for each fixture you want to add. These fixtures have a through hole for clamping long workpieces.

Air or hydraulic pressure opens and closes the collets (not included). A good choice for heavy machining, these fixtures provide a tighter hold than you can achieve with manual power. You can operate multiple fixtures with a single valve (not included) and two hoses—one for supply and one for return. All are double acting, so they need air or hydraulic pressure both to open and close. This means that the workpiece stays locked in place even if you lose pressure. Clamping force depends on the air or hydraulic pressure of your system.

Fixtures with a top-locking screw allow for direct access to make adjustments without disassembling your setup.

Fixed-length fixtures, also known as dead-length fixtures, keep the collet stationary while they clamp onto a workpiece. Use them to precisely machine holes, slots, and contours exactly where you need them. Since these fixtures position workpieces consistently, they’re often used for high-volume production runs. You can also rotate them on an indexer or rotary table without losing your reference point.

Collet Fixtures | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | Port | Connector Bushings | ||||||||||||||||||

| For Collet Type | For No. of Collets | For Max. Workpiece Dia. | Through Hole Dia. | Lg. | Wd. | Ht. | Max. Hydraulic Pressure, psi | Max. Hydraulic-Powered Clamping Force, psi | Material | No. of | Dia. | No. of Ports | Pipe Size | Thread Type | Thread Gender | Includes | Each | Each | ||

Collet Fixtures with Top-Locking Screw | ||||||||||||||||||||

Fixed Length—Flange Mount | ||||||||||||||||||||

| 3J | 1 | 1 3/4" | 1 15/16" | 4" | 4" | 3 3/4" | 5,000 | 9,500 | Steel | 4 | 3/8" | 2 | 7/16 | UNF | Female | Collet Wrench | 0000000 | 000000000 | 0000000 | 000000 |