Filter by

Material

Head Material

Color

Performance

End Shape

Pin Type

Shaft Type

End Type

Shape

Tolerance Rating

DFARS Specialty Metals

Maximum Temperature

Minimum Hardness

Hardness

Export Control Classification Number (ECCN)

Minimum Temperature

Plastic Dowel Pins

Plastic

Lg. | Dia. Tolerance | Min. Hardness | Min. Temp. | Max. Temp., ° F | Color | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wear-Resistant Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/64" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/16" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/32" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

13/64" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | -0.005" to 0.005" | Rockwell M80 | Not Rated | 220 | White | 50 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

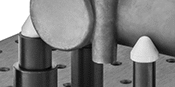

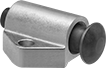

Screw-Mount Locating and Support Buttons

|

|

Flat Head |

Fixturing for Parts Inspection

Cone Supports

|

|

Dia. | Ht. | Thread Lg. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1/2" | 1/4" | Acetal | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

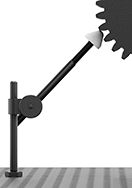

Any-Angle Cone Supports

|  |

Arm Lg. | Body Lg. | Arm Rotation | Thread Lg. | Body Material | Cone Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/4" | 4" | 360° | 1 1/8" | Steel | Acetal | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable-Height Sleeves

|  |

For Standoff Dia. | Dia. | Ht. | Material | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 1/8" | 2" | Acetal | 1/4"-20 Knurled Knob | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

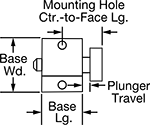

Spring-Loaded Guide Plungers

Round Face

|  |  |

Triangular Base | Rectangular Base |

Base | Mounting Hole | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face Dia. | Plunger Travel | Shape | Lg. | Wd. | Spring Force, lbf | Body Material | No. of | Dia. | Ctr.-to-Ctr. Wd. | Ctr.-to-Face Lg. | Mounting Fasteners Included | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.38" | 1/8" | Triangle | 0.688" | 0.875" | 1.5 to 2.5 | Aluminum | 2 | 0.138" | 0.656" | 0.593" | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.38" | 1/8" | Triangle | 0.688" | 0.875" | 5.1 to 14.6 | Aluminum | 2 | 0.136" | 0.656" | 0.593" | No | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.56" | 3/16" | Rectangle | 1" | 1.5" | 2.3 to 25.8 | Aluminum | 2 | 0.203" | 1.125" | 0.875" | No | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.81" | 1/4" | Rectangle | 1.375" | 2" | 16.5 to 47.5 | Aluminum | 2 | 0.266" | 1.5" | 1.218" | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

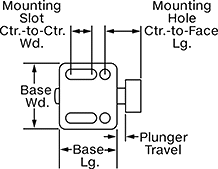

Square Face

|  |

Rectangular Base 2 Mounting Slots | 2 Mounting Slots 2 Mounting Holes |

Base | Mounting Slot | Mounting Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face Wd. | Plunger Travel | Shape | Lg. | Wd. | Spring Force, lbf | Body Material | No. of | Lg. | Wd. | Ctr.-to-Ctr. Wd. | No. of | Dia. | Ctr.-to-Ctr. Wd. | Ctr.-to-Face Lg. | Mounting Fasteners Included | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Face—Adjustable | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.39" | 1/8" | Rectangle | 0.65" | 0.866" | 1.8 to 2.4 | Zinc Alloy | 2 | 0.307" | 0.13" | 0.551" | 2 | 0.13" | 0.551" | 0.457" | No | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.39" | 1/8" | Rectangle | 0.65" | 0.866" | 2.5 to 4.5 | Zinc Alloy | 2 | 0.307" | 0.13" | 0.551" | 2 | 0.13" | 0.551" | 0.457" | No | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.63" | 3/16" | Rectangle | 1.083" | 1.25" | 1.8 to 4.2 | Zinc Alloy | 2 | 0.606" | 0.213" | 0.827" | 2 | 0.213" | 0.827" | 0.689" | No | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.63" | 3/16" | Rectangle | 1.083" | 1.25" | 4.3 to 10.1 | Zinc Alloy | 2 | 0.606" | 0.213" | 0.827" | 2 | 0.213" | 0.827" | 0.689" | No | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.87" | 5/16" | Rectangle | 1.375" | 1.5" | 3.9 to 7.4 | Zinc Alloy | 2 | 0.787" | 0.25" | 1.063" | 2 | 0.25" | 1.063" | 0.972" | No | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.87" | 5/16" | Rectangle | 1.375" | 1.5" | 6.1 to 16.8 | Zinc Alloy | 2 | 0.787" | 0.25" | 1.063" | 2 | 0.25" | 1.063" | 0.972" | No | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

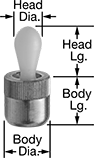

Spring Locating Pins

Pins | Installation Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Body | Head | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dia. | Lg. | Dia. | Lg. | Max. Head Movement | Min. Spring Force, lbf | Max. Spring Force, lbf | Body Dia. Tolerance | Body Material | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 0.28" | 0.12" | 0.16" | 0.04" | 2.3 | 2.5 | 0" to 0.0009" | Aluminum | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.44" | 0.38" | 0.24" | 0.41" | 0.08" | 13.5 | 14.8 | 0" to 0.0011" | Aluminum | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.44" | 0.43" | 0.24" | 0.43" | 0.08" | 9 | 9.9 | 0" to 0.0011" | Aluminum | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5" | 0.51" | 0.31" | 0.53" | 0.1" | 11.3 | 12.4 | 0" to 0.0011" | Aluminum | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.63" | 0.67" | 0.39" | 0.64" | 0.13" | 22.5 | 24.8 | 0" to 0.0011" | Aluminum | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 7 mm | 3 mm | 4 mm | 1 mm | 2.3 | 2.5 | 0 mm to 0.022 mm | Aluminum | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 11 mm | 5 mm | 6.7 mm | 1.6 mm | 4.5 | 5 | 0 mm to 0.027 mm | Aluminum | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 11 mm | 6 mm | 10.7 mm | 2 mm | 9 | 9.9 | 0 mm to 0.027 mm | Aluminum | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 13 mm | 8 mm | 13.9 mm | 2.6 mm | 11.3 | 12.4 | 0 mm to 0.027 mm | Aluminum | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 17 mm | 10 mm | 16.7 mm | 3.2 mm | 22.5 | 24.8 | 0 mm to 0.027 mm | Aluminum | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||