Filter by

For Use With

Container Size

Housing Material

Discharge Connection

Flow Rate

Intake Tube Material

Drum Pump Type

Intake Tube Length

Discharge Location

Pump Type

Maximum Temperature

DFARS Specialty Metals

Maximum Flow Rate

Continuous-Flow Drum Pumps for Water and Chemicals

Temp. | Intake | Discharge (Spout End) | Discharge (Pump Body) | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | For Hose ID | Connection | Gender | Connection | Pipe Size | Gender | Thread Type | Spout Type | Drum Pump Type | Each | |||

| 8 | 15 to 55 | 319 | Not Rated | 100 | 2 NPT | Drum Connector | 1 1/4" | 44 1/2" | Spout End Pump Body | 1" | Barbed | Male | Threaded | 3/4 | Female | BSPP | Removable | Crank Handle | 00000000 | 0000000 | ||

Foot-Operated Drum Pumps for Harsh Chemicals

Temp., ° F | Intake | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Spout Type | Drum Pump Type | Each | |||

| 5 | 30 | 500 | 35 | 100 | 1 1/8" to 2 3/4" | Drum Connector | 5/8" | 13" to 28" | Spout End | Removable | Pedal | 0000000 | 0000000 | ||

Drum Pumps for Water and Chemicals

|  |  |  |  |  |

Style A | Style B | Style C (Shown with Connector) | Style D | Style E | Style F |

Style A

Temp. | Intake | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5 to 15 | 700 | Not Rated | 120 | 2 NPT | Drum Connector | 1 1/2" | 22" | Spout End | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 15 to 55 | 700 | Not Rated | 120 | 2 NPT | Drum Connector | 1 1/2" | 39" | Spout End | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style B

Drum Pumps | Replacement Connectors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | Pipe Size | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5 | 750 | 40 | 120 | 70 mm | Drum Connector | 1/2" | 13" | Tube End | 7/16" | 5/8" | 22" | PVC | 00000000 | 000000 | 2 NPT | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5 to 15 | 700 | Not Rated | 120 | 2 NPT | Drum Connector | 1 1/2" | 22" | Tube End | 7/16" | 5/8" | 22" | PVC | 0000000 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 15 to 55 | 700 | Not Rated | 120 | 2 NPT | Drum Connector | 1 1/2" | 39" | Tube End | 7/16" | 5/8" | 36" | PVC | 0000000 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CSM Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 5 to 15 | 2,500 | 35 | 120 | 1/2" | 18" | Tube End | 7/16" | 9/16" | 9" | PVC | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style D

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CSM Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 5 | 2,500 | 35 | 120 | 61 mm | Drum Connector | 1/2" | 14 1/2" | Tube End | 7/16" | 9/16" | 36" | PVC | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 5 | 2,500 | 35 | 120 | 63 mm | Drum Connector | 1/2" | 14 1/2" | Tube End | 7/16" | 9/16" | 36" | PVC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 5 | 2,500 | 35 | 120 | 70 mm | Drum Connector | 1/2" | 14 1/2" | Tube End | 7/16" | 9/16" | 36" | PVC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style E

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CSM Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 5 to 30 | 2,500 | 35 | 120 | 2 NPT | Drum Connector | 1/2" | 18" | Tube End | 7/16" | 9/16" | 48" | PVC | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Viton® Fluoroelastomer Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 5 to 55 | 2,500 | 35 | 120 | 2 NPT | Drum Connector | 9/16" | 36" | Tube End | 7/16" | 9/16" | 9" | PVC | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style F

Drum Pumps | Connectors | Replacement Connectors | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Each | Connection | Each | Pipe Size | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Viton® Fluoroelastomer Piston | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 2,500 | 35 | 120 | 2 NPT | Drum Connector | 1 1/2" | 38" | Tube End | 1 1/4" | 1 1/2" | 36" | Polyethylene | 0000000 | 0000000 | 2 5/8"-5 Buttress | 0000000 | 000000 | 2 NPT | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 2,500 | 35 | 120 | 2 NPT | Drum Connector | 1 1/2" | 38" | Tube End | 1 1/4" | 1 1/2" | 72" | Polyethylene | 0000000 | 000000 | 2 5/8"-5 Buttress | 0000000 | 00000 | 2 NPT | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 2,500 | 35 | 120 | 2" | Drum Connector | 1 1/2" | 38" | Tube End | 1 1/4" | 1 1/2" | 36" | Polyethylene | 0000000 | 000000 | 2 5/8"-5 Buttress | 0000000 | 00000 | 2 NPT | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 2,500 | 35 | 120 | 2" | Drum Connector | 1 1/2" | 38" | Tube End | 1 1/4" | 1 1/2" | 72" | Polyethylene | 00000000 | 000000 | 2 5/8"-5 Buttress | 0000000 | 00000 | 2 NPT | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drum Pumps for Harsh Chemicals

Electric Drum Pump Systems for Water, Oil, Coolants, and Chemicals

Temp. | Intake | Discharge | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | Power, hp | Current, amp | For Drum Opening Size | Tube OD | Tube Lg. | Tube ID | Tube OD | Tube Lg. | Hazardous Location Rating | Enclosure Rating | Connection | No. of Blades | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—NEMA 5-15 Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polypropylene Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15 | 55 | 1,500 | Not Rated | 130 | 1 | 7.5 | 2 NPT | 1 5/8" | 39" | 1" | 1 1/4" | 72" | — | IP44 | Straight Blade | 3 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15 | 55 | 1,500 | Not Rated | 130 | 1 | 7.5 | 2 NPT | 1 5/8" | 47" | 1" | 1 1/4" | 72" | — | IP44 | Straight Blade | 3 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 15 | 55 | 1,500 | Not Rated | 175 | 1 | 7.5 | 2 NPT | 1 1/2" | 39" | 1" | 1 1/4" | 72" | — | IP44 | Straight Blade | 3 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 15 | 55 | 1,500 | Not Rated | 175 | 1 | 7.5 | 2 NPT | 1 1/2" | 47" | 1" | 1 1/4" | 72" | — | IP44 | Straight Blade | 3 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVDF Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15 | 55 | 1,500 | Not Rated | 175 | 1 | 7.5 | 2 NPT | 1 5/8" | 39" | 1" | 1 1/4" | 72" | — | IP54 | Straight Blade | 3 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15 | 55 | 1,500 | Not Rated | 175 | 1 | 7.5 | 2 NPT | 1 5/8" | 47" | 1" | 1 1/4" | 72" | — | IP54 | Straight Blade | 3 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 15 | 55 | 1,000 | Not Rated | 175 | 1 1/3 | 9.1 | 2 NPT | 1 1/2" | 39" | 1" | 1 1/4" | 72" | NEC Class I Divisions 1, 2 Group D | IP55 | — | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric Drum Pumps for Water, Oil, and Chemicals

|  |

Style A | Style B |

Style A

Temp., ° F | Intake | Discharge | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Container Size, gal. | Flow Rate, gpm | Discharge Pressure, psi | Max. Viscosity, cP | Min. | Max. | Power, hp | Current, amp | For Drum Opening Size | Tube OD | Tube Lg. | Tube ID | Tube OD | Tube Lg. | Connection | No. of Blades | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Plug In—With Thermal Overload Protection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 to 5 | 7, 17 | 8 | 300 | 0 | 150 | 0.15 | 2 | 1 1/2" | 1 1/4" | 16" | 3/4" | 1" | 60" | Straight Blade | 2 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 7, 17 | 8 | 300 | 0 | 150 | 0.15 | 2 | 1 1/2" | 1 1/4" | 40" | 3/4" | 1" | 60" | Straight Blade | 2 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style B

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. | Intake | Discharge | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Container Size, gal. | Flow Rate, gpm | Discharge Pressure, psi | Max. Viscosity, cP | Min. | Max., ° F | Power, hp | Current, amp | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Tube ID | Tube OD | Tube Lg. | Connection | No. of Blades | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 17 | 7 | 1,000 | Not Rated | 180 | 1/2 | 6.3 | 2 NPT | Drum Connector | 1 1/2" | 39 1/2" | 1" | 1 1/4" | 60" | Straight Blade | 3 | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Easy-Stroke Drum Pumps for Water, Coolant, and Chemicals

Temp., ° F | Intake | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Drum Pump Type | Each | |||

| B | 11 | 15 to 55 | 250 | -15 | 150 | 2 NPT | Drum Connector | 1" | 19 3/4" to 35 1/2" | Spout End | Lever Handle | 0000000 | 0000000 | ||

Adjustable-Flow Easy-Stroke Drum Pumps for Water and Chemicals

|  |

PPS Housing | 304 Stainless Steel Housing |

Temp. | Intake | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | For Discharge Tube ID | Spout Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PPS Intake Tube and PPS Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8, 10, 12 | 15 to 55 | 500 | Not Rated | 180 | 1 1/2 NPT, 2 NPT | Drum Connector | 1 5/8" | 24 1/2" to 34 1/2" | 1" | Removable | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Intake Tube and 304 Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6, 8, 10, 12 | 15 to 55 | 2,000 | Not Rated | 140 | 1 1/2 NPT, 2 NPT | Drum Connector | 1 1/8" | 18 1/2" to 32 1/2" | 11/16" | Removable | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable-Flow Electric Drum Pumps for Water, Oil, Coolants, and Chemicals

Tube-End Discharge

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Power, hp | Current, amp | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Tube ID | Tube OD | Tube Lg. | Connection | No. of Blades | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Plug In—With Thermal Overload Protection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 0 to 18.5 | 9 | 30 | 300 | 15 | 120 | 1/4 | 1.5 | 32 mm | Wall Bracket | 1 1/4" | 27" | 3/4" | 1" | 60" | Straight Blade | 2 | 00000000 | 0000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 0 to 18.5 | 9 | 55 | 300 | 15 | 120 | 1/4 | 1.5 | 32 mm | Wall Bracket | 1 1/4" | 39" | 3/4" | 1" | 60" | Straight Blade | 2 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pump Body

Drum Pumps | Pump Repair Kits | Connectors | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. | Intake | Discharge (Pump Body) | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | Power, hp | Current, amp | For Drum Opening Size | Tube OD | Tube Lg. | Connection | For Tube ID | Connection | No. of Blades | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Plug In—With Thermal Overload Protection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 0 to 35 | 16 | 55 | 1,500 | Not Rated | 130 | 1 | 8.5 | 2" | 1 5/8" | 39" | Barbed | 1" | Straight Blade | 3 | 0000000 | 000000000 | 0000000 | 0000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 0 to 35 | 16 | 55 | 1,500 | Not Rated | 130 | 1 | 8.5 | 2" | 1 5/8" | 47" | Barbed | 1" | Straight Blade | 3 | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 0 to 35 | 16 | 55 | 1,500 | Not Rated | 175 | 1 | 8.5 | 2" | 1 1/2" | 39" | Barbed | 1" | Straight Blade | 3 | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 0 to 35 | 16 | 55 | 1,500 | Not Rated | 175 | 1 | 8.5 | 2" | 1 1/2" | 47" | Barbed | 1" | Straight Blade | 3 | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 0 to 35 | 16 | 55 | 1,500 | Not Rated | 175 | 1 | 8.5 | 2" | 1 5/8" | 39" | Barbed | 1" | Straight Blade | 3 | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Compact Drum Pumps for Water and Chemicals

Temp., ° F | Intake | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Spout Type | Drum Pump Type | Each | |||

| A | 2, 4, 6, 8 | 5 | Not Rated | Not Rated | 125 | 3/4 NPT | — | 5/8" | 18 1/4" | Spout End | Fixed | Plunger | 0000000 | 000000 | ||

| A | 2, 4, 6, 8 | 15 to 55 | Not Rated | Not Rated | 125 | 3/4 NPT, 2 NPT | Two Drum Connectors | 5/8" | 33" | Spout End | Fixed | Plunger | 0000000 | 00000 | ||

| A | 4, 8, 12, 16 | 15 to 55 | Not Rated | Not Rated | 125 | 3/4 NPT, 2 NPT | Two Drum Connectors | 5/8" | 33" | Spout End | Fixed | Plunger | 0000000 | 00000 | ||

| B | 3 | 55 | Not Rated | 40 | 150 | 2 NPT | Drum Connector | 1 3/4" | 32" | Spout End | Flexible | Plunger | 0000000 | 000000 | ||

Siphon Drum Pumps

|  |

Style A | Style B |

Temp., ° F | Intake | Discharge | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Drum Pump Type | Each | |||

| A | 2 | 1 to 5 | 26 | 50 | 120 | — | — | 5/8" | 14 1/2" | Tube End | 1/2" | 5/8" | 20 1/2" | LDPE | Siphon | 0000000 | 00000 | ||

| A | 2 | 5 | 150 | Not Rated | 140 | — | — | 11/16" | 16" | Tube End | 9/16" | 11/16" | 21" | Polyethylene | Siphon | 0000000 | 0000 | ||

| A | 5 | 15 to 55 | 88 | Not Rated | 140 | 2 NPT | Drum Connector | 7/8" | 34" | Tube End | 13/16" | 1" | 48" | Polyethylene | Siphon | 0000000 | 00000 | ||

| A | 7 | 15 to 55 | 88 | Not Rated | 140 | 2 NPT | Drum Connector | 1" | 34" | Tube End | 13/16" | 1" | 48" | Polyethylene | Siphon | 0000000 | 00000 | ||

| B | 5 to 7 | 5 | 650 | Not Rated | 140 | 2 NPS, 70 mm | Drum Connector | 1 1/2" | 16" | Tube End | 1" | 1 1/4" | 60" | PVC | Siphon | 0000000 | 00000 | ||

| B | 5 to 7 | 5 to 6 | 650 | Not Rated | 140 | 2 NPS | Drum Connector | 1 1/2" | 16" | Tube End | 1" | 1 1/4" | 60" | PVC | Siphon | 0000000 | 00000 | ||

| B | 5 to 7 | 15 | 650 | Not Rated | 140 | 2 NPS | Drum Connector | 1 1/2" | 24" | Tube End | 1" | 1 1/4" | 60" | PVC | Siphon | 0000000 | 00000 | ||

Air-Powered Drum Pumps for Water, Oil, Coolants, and Chemicals

With NPT Discharge

Temp., ° F | Intake | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Pipe Connection | Each | ||

| 14 | 55 | 1,500 | -30 | 300 | 40 to 80 | 27 | 2 NPT | Drum Connector | 1/8 Female NPT | 1 1/2" | 39" | 3/4 Female NPT | 00000000 | 0000000 | |

With Tube-End Discharge

Temp., ° F | Intake | Discharge (Tube End) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | ID | Lg., ft. | Each | ||

| 15 | 30 | 300 | 35 | 150 | 40 | 27 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 1/4" | 27" | 3/4" | 5 | 000000 | 0000000 | |

| 15 | 55 | 300 | 35 | 150 | 40 | 27 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 1/4" | 40" | 3/4" | 5 | 000000 | 000000 | |

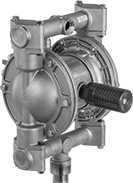

Polypropylene Long-Life Air-Powered Drum Pumps for Chemicals

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Connection | Pipe Size | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Santoprene Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 55 | 3,000 | 30 | 180 | 100 | 12 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 1/2 Female NPT | 36" | Pump Body | Threaded | 1/2 Female NPT | 0000000 | 0000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 31 | 55 | 8,000 | 30 | 180 | 100 | 40 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 3/4 Female NPT | 36" | Pump Body | Threaded | 3/4 Female NPT | 0000000 | 00000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 55 | 3,000 | 40 | 180 | 100 | 12 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 1/2 Female NPT | 36" | Pump Body | Threaded | 1/2 Female NPT | 0000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 8,000 | 40 | 180 | 100 | 40 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 3/4 Female NPT | 36" | Pump Body | Threaded | 3/4 Female NPT | 0000000 | 00000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drum Pumps for Food and Beverage

Temp., ° F | Intake | Discharge | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Tube ID | Tube Lg. | Tube Material | Drum Pump Type | Food Industry Std. | Choose a Strap Color | Each | |||

| B | 12 | 5 | 8,800 | 35 | 140 | 2 NPT | 5 Gallon Pail Adapter, Drum Connector | 1 5/8" | 16 1/2" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | White | 0000000 | 000000 | ||

| B | 15 | 5 | 8,800 | 40 | 120 | 2 NPT | 5 Gallon Pail Adapter, Drum Connector | 1 1/2" | 16 1/2" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | Black , Blue | 00000000 | 00000 | ||

| B | 15 | 15, 30 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 30" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | Green | 0000000 | 00000 | ||

| B | 15 | 30 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 11/16" | 30" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | White | 0000000 | 00000 | ||

| B | 15 | 55 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 36" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | Black , Blue , Green , Orange , Purple | 00000000 | 00000 | ||

| B | 15 | 55 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 11/16" | 45" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | White | 0000000 | 00000 | ||

| C | 12 | 5 | 8,800 | 35 | 140 | 2 NPT | 5 Gallon Pail Adapter, Drum Connector | 1 5/8" | 16 1/2" | Tube End | 3/4" | 33" | PVC | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | White | 0000000 | 00000 | ||

| C | 15 | 55 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 36" | Tube End | 3/4" | 32 1/2" | PVC | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | Black , Blue , Yellow | 00000000 | 00000 | ||

| D | 15 | 275 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 46 1/2" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | — | 0000000 | 000000 | ||

| E | 15 | 15, 30 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 30" | Tube End | 3/4" | 32 1/2" | PVC | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | — | 0000000 | 00000 | ||

| E | 15 | 55 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 36" | Tube End | 3/4" | 32 1/2" | PVC | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | — | 0000000 | 00000 | ||

High-Flow Electric Drum Pumps for Water, Oil, Coolants, and Chemicals

Temp., ° F | Intake | Discharge | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Discharge Pressure, psi | Max. Viscosity, cP | Min. | Max. | Power, hp | Current, amp | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Tube ID | Tube OD | Tube Lg. | Tube Material | Connection | No. of Blades | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 30 | 35 | 500 | 35 | 160 | 1/2 | 5.7 | 2 NPT | Drum Connector | 2" | 27" | Tube End | 1" | 1 5/16" | 60" | PVC | Straight Blade | 3 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 55 | 35 | 500 | -20 | 220 | 1/2 | 5.7 | 2 NPT | Drum Connector | 2" | 40" | Tube End | 1" | 1 5/16" | 60" | PVC | Straight Blade | 3 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 55 | 35 | 500 | -20 | 220 | 1/2 | 5.7 | 2 NPT | Drum Connector | 2" | 48" | Tube End | 1" | 1 5/16" | 60" | PVC | Straight Blade | 3 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 55 | 35 | 500 | 35 | 160 | 1/2 | 5.7 | 2 NPT | Drum Connector | 2" | 40" | Tube End | 1" | 1 5/16" | 60" | PVC | Straight Blade | 3 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 55 | 35 | 500 | 35 | 160 | 1/2 | 5.7 | 2 NPT | Drum Connector | 2" | 48" | Tube End | 1" | 1 5/16" | 60" | PVC | Straight Blade | 3 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hazardous Location Electric Drum Pumps for Water, Oil, Coolants, and Chemicals

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge (Pump Body) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Discharge Pressure, psi | Max. Viscosity, cP | Min. | Max. | Power, hp | Current, amp | For Drum Opening Size | Tube OD | Tube Lg. | Discharge Location | Connection | For Tube ID | Gender | Certification | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—Hardwire—With Thermal Overload Protection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48.5 | 55 | 14 | 300 | -40 | 210 | 1/2 | 5.3 | 41 mm | 1 5/8" | 39" | Pump Body | Barbed | 1" | Male | C-UL Listed UL Listed | 00000000 | 000000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drum Pumps for Diesel Exhaust Fluid

Temp., ° F | Discharge | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | For Intake Tube OD | Discharge Location | Connection | Hose OD | Hose Length, ft. | Hose Material | Drum Pump Type | Nozzle Type | Each | |||

| 11 | 55 to 275 | 1.5 | 35 | 110 | 2" | Drum Connector | 1" | Hose and Nozzle | Barbed | 3/4" | 12 | EPDM | Lever Handle | Automatic Shutoff | 000000 | 0000000 | ||

High-Pressure Air-Powered Drum Pumps for Chemicals

Temp., ° F | Intake | Discharge | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | |||

| 4 | 5 | 5,000 | 35 | 120 | 180 | 1.5 | 2 NPT | — | 1/4 Female NPT | 2 1/8" | 10" | Pump Body | Threaded | 3/4 Female NPT | 000000 | 000000000 | ||

| 4 | 55 | 5,000 | 35 | 120 | 180 | 1.5 | 2 NPT | Drum Connector | 1/4 Female NPT | 2 1/8" | 36" | Pump Body | Threaded | 3/4 Female NPT | 000000 | 00000000 | ||

PVDF Long-Life Air-Powered Drum Pumps for Chemicals

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Connection | Pipe Size | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 55 | 3,000 | 40 | 210 | 100 | 12 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 1/2 Female NPT | 36" | Pump Body | Threaded | 1/2 Female NPT | 0000000 | 000000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Foot-Operated Drum Pumps for Water and Oil

Temp., ° F | Intake | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Spout Type | Drum Pump Type | Each | |||

| 6 | 55 | 500 | 35 | 100 | 1 1/8" to 2 3/4" | Drum Connector | 1/2" | 19" to 35" | Spout End | Fixed | Pedal | 0000000 | 0000000 | ||

Nondrip Drum Pumps for Water and Chemicals

Drum Pumps for Water and Coolant

Drum Pumps | Pump Repair Kits | Replacement Connectors | Pail Adapters | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp. | Intake | |||||||||||||||||||

Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Each | Each | Pipe Size | Each | Each | ||||||

| 8 | 5 to 15 | 300 | Not Rated | 140 | 2 NPT | Drum Connector | 1/2" | 22 1/2" | Spout End | 0000000 | 0000000 | 0000000 | 000000 | 2 NPT | 0000000 | 000000 | 0000000 | 000000 | ||

| 16 | 15 to 55 | 300 | Not Rated | 140 | 2 NPT | Drum Connector | 1 1/8" | 39 1/2" | Spout End | 0000000 | 000000 | 0000000 | 00000 | 2 NPT | 0000000 | 00000 | ——— | 0 | ||

Remote-Adjustment High-Pressure Peristaltic Pumps for Chemicals

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gal/day | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, ° F | Power | Current, amp | Intake Connection | Discharge Connection | Lg. | Wd. | Ht. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase with With Thermal Overload Protection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.3 to 125 | 100 | 1,500 | 32 to 100 | Not Rated | 0.6 | Compression | Compression | 11" | 8 3/4" | 8 1/8" | 20 ft. of 3/8" OD Tubing | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nondrip Drum Pumps for Fuel and Flammable Liquid

Drum Pumps | Tap Kits | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | ||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Drum Pump Type | Nozzle Type | Features | Flammability Rating | Each | Each | ||||

| 4.5 | 2 to 55 | 270 | 35 | 110 | 2 NPT | Drum Connector | 5/8" | 40" | Nozzle | Plunger | Nondrip | — | — | 0000000 | 0000000 | 0000000 | 0000000 | ||

| 4.5 | 2 to 55 | 270 | 35 | 110 | 2 NPT | Drum Connector | 5/8" | 40" | Nozzle | Plunger | Nondrip | Bonding and Grounding Wires | NFPA 30 18.4.4.1 | 0000000 | 000000 | ——— | 0 | ||

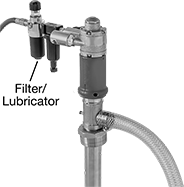

Air-Powered Drum Pumps with Hose and Filter/Lubricator for Water, Oil, Coolants, and Chemicals

Drum Pumps | Pump Repair Kits | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | ||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Tube ID | Tube Lg., ft. | Tube Material | Features | Each | Each | ||||

| 16 | 55 | 2,000 | -20 | 150 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 1/2" | 40" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 0000000 | 000000000 | 0000000 | 0000000 | ||

| 16 | 55 | 2,000 | 35 | 150 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 5/8" | 40" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 0000000 | 00000000 | 0000000 | 000000 | ||

| 22 | 55 | 330 | 35 | 160 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 2" | 40" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 0000000 | 00000000 | ——— | 0 | ||

| 22 | 55 | 330 | 35 | 160 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 2" | 48" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 0000000 | 00000000 | ——— | 0 | ||

Stainless Steel Long-Life Air-Powered Drum Pumps for Chemicals

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Connection | Pipe Size | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 8,000 | 40 | 210 | 100 | 40 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 3/4 Female NPT | 39" | Pump Body | Threaded | 3/4 Female NPT | 0000000 | 000000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Drum Pumps for Flammable Liquid

Temp., ° F | Intake | Discharge (Pump Body) | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Connection | For Tube ID | Gender | Certification | Features | Each | |||

| 26 | 55 | 1,100 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 39" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 0000000 | 000000000 | ||

| 26 | 55 | 1,100 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 47" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 0000000 | 00000000 | ||

| 53 | 55 | 1,000 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 39" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 0000000 | 00000000 | ||

| 53 | 55 | 1,000 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 47" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 0000000 | 00000000 | ||

Air-Powered Drum Pumps with Sanitary Quick-Clamp Fittings for Food and Beverage

Temp., ° F | Intake | Discharge | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Connection | For Tube OD | Food Industry Std. | Each | |||

| 2.5 | 55 | 25,000 | 35 | 180 | 100 | 6 | 2 NPT | Drum Connector | 3/8 Female NPT | 2" | 37 1/2" | Pump Body | Quick Clamp | 1" | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 000000 | 000000000 | ||

High-Pressure Air-Powered Drum Pumps for Fuel and Flammable Liquid

Temp., ° F | Intake | Discharge | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | |||

| 4 | 55 | 7,500 | 40 | 200 | 0 to 150 | 10 | 2 NPT | Drum Connector | 1/4 Female NPT | 2 1/8" | 33 11/16" | Pump Body | Threaded | 3/4 Female NPT | 0000000 | 000000000 | ||

Stainless Steel Long-Life Air-Powered Drum Pumps for Food and Beverage

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Connection | For Tube OD | Tube Lg. | Discharge Location | Connection | For Tube OD | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 55 | 8,000 | 40 | 210 | 100 | 40 | 2 NPT | Drum Connector | 1/4 Female NPT | Quick Clamp | 1" | 39" | Pump Body | Quick Clamp | 1" | 0000000 | 000000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||