How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

How to Install Key-Locking Inserts

More

About Nuts, Materials, and Finishes

More

About Threaded Studs and Rods

More

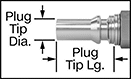

Minimal-Spill Quick-Disconnect Hose Couplings for Coolant

Reduce the risk of spills near electronics when connecting and disconnecting liquid cooling lines. Also known as double shut-off couplings, these couplings have a shut-off valve on both sides that stops the flow of coolant if they’re separated. Often used to connect servers to a cooling manifold in data centers, they comply with the performance specifications of OCP (Open Computing Project). To avoid mixing up your lines, choose blue couplings for cold supply and red couplings for hot return. A complete coupling consists of a plug and socket or two adapters (all sold separately).

Install plugs on manifolds and servers. They’re also known as nipples.

UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

- Maximum Pressure: See Table

- Temperature Range: -40° to 300° F

- Material: 303 Stainless Steel

- Compatible With: Danfoss Hansen UQD

Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Thread Size | Dash Size | Max. Pressure | Each | |

Red | |||||||

| 1/2 | 1 7/16" | 11/16" | 7/16"-14 | 10 | 100 psi @ 72° F | 0000000 | 000000 |

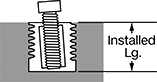

18-8 Stainless Steel Easy-to-Install Thread-Locking Inserts

Made of 18-8 stainless steel, these inserts have good corrosion resistance. Also known as E-Z Lok, they use Loctite® adhesive to keep them in place. The adhesive reaches full strength after 72 hours. They may be mildly magnetic. Installation requires a drill bit and a standard tap. Then set the insert with an installation bit, a slotted screwdriver, or a bolt with two nuts.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

Inserts | Installation Bits | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | Drive Style | Pkg. Qty. | Pkg. | Each | ||

18-8 Stainless Steel with Thin Wall | ||||||||||

| 7/16"-14 | 9/16"-18 | 0.563" | 33/64" | 0.5156" | Slotted | 1 | 000000000 | 00000 | 000000000 | 00000 |

18-8 Stainless Steel with Thick Wall | ||||||||||

| 7/16"-14 | 5/8"-11 | 21/32" | 17/32" | 17/32" | Slotted | 1 | 000000000 | 0000 | 000000000 | 0000 |

Black-Phosphate Steel Easy-to-Install Thread-Locking Inserts

A black-phosphate finish provides mild corrosion resistance. Also known as E-Z Lok, these inserts use Loctite® adhesive to keep them in place. The adhesive reaches full strength after 72 hours. Installation requires a drill bit and a standard tap. Then set the insert with a bolt and two nuts, or use an installation bit.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

To drive slotted inserts, you can use a slotted screwdriver instead of using an installation bit or a bolt and two nuts.

Inserts | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For Tap | Installation Bits | |||||||||

| Thread Size | Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | Drive Style | Pkg. Qty. | Pkg. | Each | ||

Black-Phosphate Steel with Thin Wall | ||||||||||

| 7/16"-14 | 9/16"-12 | 9/16" | 33/64" | 33/64" | Slotted | 5 | 000000000 | 00000 | 000000000 | 00000 |

Black-Phosphate Steel with Thick Wall | ||||||||||

| 7/16"-14 | 5/8"-11 | 21/32" | 17/32" | 17/32" | Slotted | 5 | 000000000 | 0000 | 000000000 | 0000 |

18-8 Stainless Steel Key-Locking Inserts

Made of stainless steel, these inserts have good corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

Inserts with an extra-thick wall are stronger than thick- and thin-wall inserts. Use them to reduce the size of tapped holes.

Inserts | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Each | Installation Tools | |||||||||

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | 1-9 | 10-Up | Each | ||

18-8 Stainless Steel with Thin Wall | ||||||||||

| 7/16"-14 | 9/16"-12 | 9/16" | 33/64" | 0.516" | 4 | 000000000 | 000000 | 000000 | 000000000 | 000000 |

18-8 Stainless Steel with Thick Wall | ||||||||||

| 7/16"-14 | 5/8"-11 | 5/8" | 37/64" | 0.578" | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 |

18-8 Stainless Steel with Extra Thick Wall | ||||||||||

| 7/16"-14 | 3/4"-16 | 5/8" | 45/64" | 0.703" | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 |

Mil. Spec. Stainless Steel Key-Locking Inserts

These inserts are made to stringent military specifications. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

Inserts | Installation Tools | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | Specifications Met | Each | Each | ||

18-8 Stainless Steel with Thin Wall | ||||||||||

| 7/16"-14 | 9/16"-12 | 9/16" | 33/64" | 0.521" | 4 | MS51830-109 | 000000000 | 00000 | 000000000 | 000000 |

18-8 Stainless Steel with Extra Thick Wall | ||||||||||

| 7/16"-14 | 11/16"-11 | 5/8" | 41/64" | 0.646" | 4 | MS51832-105 | 000000000 | 00000 | 000000000 | 00000 |

Black-Phosphate Steel Key-Locking Inserts

A black-phosphate finish provides mild corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole with stripped threads.

Inserts with an extra thick wall are stronger than thick- and thin-wall inserts. Use them to reduce the size of tapped holes.

Inserts | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Each | Installation Tools | |||||||||

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | 1-9 | 10-Up | Each | ||

Black-Phosphate Steel with Thin Wall | ||||||||||

| 7/16"-14 | 9/16"-12 | 9/16" | 33/64" | 33/64" | 4 | 000000000 | 00000 | 00000 | 000000000 | 000000 |

Black-Phosphate Steel with Thick Wall | ||||||||||

| 7/16"-14 | 5/8"-11 | 5/8" | 37/64" | 37/64" | 4 | 000000000 | 0000 | 0000 | 000000000 | 00000 |

Black-Phosphate Steel with Extra Thick Wall | ||||||||||

| 7/16"-14 | 3/4"-16 | 5/8" | 45/64" | 45/64" | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 |

Mil. Spec. Alloy Steel Key-Locking Inserts

The strongest key-locking inserts we offer, these inserts are made to stringent military specifications. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

Inserts | Installation Tools | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | Specifications Met | Each | Each | ||

Cadmium-Plated Alloy Steel with Thin Wall | ||||||||||

| 7/16"-14 | 9/16"-12 | 9/16" | 33/64" | 33/64" | 4 | MS51830A109 | 000000000 | 00000 | 000000000 | 000000 |

Cadmium-Plated Alloy Steel with Thick Wall | ||||||||||

| 7/16"-14 | 5/8"-11 | 5/8" | 37/64" | 37/64" | 4 | MS51831A105 | 000000000 | 0000 | 000000000 | 00000 |

Aligning Key-Locking Inserts

Install threads that align with off-center parts. These inserts have floating threads that account for misalignment, allowing you to insert screws at a slight angle as you fasten two parts together. With keys that drive into the surrounding material, they have a more secure hold than thread-locking inserts. Use them to repair or add new threads in soft metal, such as aluminum. They’re a close alternative to Keensert® inserts. Install them using a drill bit, a standard tap, an installation tool, and a hammer.

Alloy steel inserts are among the strongest we offer. The cadmium plating protects them from corroding in wet environments. They may be mildly magnetic. These inserts have a thick wall that’s best suited for large holes. They’re often used to replace damaged threads that have been drilled out.

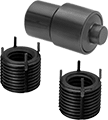

Key-Locking Insert Assortments with Installation Tool

These assortments include various sizes of key-locking inserts with thick and thin walls, and an installation tool. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or convert threads in soft metals such as aluminum. They’re comparable to Keensert® inserts.

18-8 stainless steel inserts are more corrosion resistant than black-phosphate steel. They may be mildly magnetic.

Black-phosphate steel inserts are mildly corrosion resistant.

Thin-wall inserts are often used in small holes or near the edge of a workpiece.

Choose assortments with thick-wall inserts for greater strength than thin-wall inserts, or to fill a large hole.

For Tap | ||||||

|---|---|---|---|---|---|---|

| Includes | No. of Inserts Included | Thread Size | Drill Bit Size | For Max. Hole Dia. | Each | |

Inch | ||||||

18-8 Stainless Steel with Thin Wall | ||||||

| 10-24 Thread × 0.313" Installed Lg. (20 Each) 1/4"-20 Thread × 3/8" Installed Lg. (20 Each) 5/16"-18 Thread × 0.438" Installed Lg. (15 Each) 3/8"-16 Thread × 1/2" Installed Lg. (10 Each) 7/16"-14 Thread × 0.563" Installed Lg. (10 Each) 1/2"-13 Thread × 5/8" Installed Lg. (6 Each) Installation Tool | 81 | 5/16"-18 3/8"-16 7/16"-14 1/2"-13 9/16"-12 5/8"-11 | I Q X 29/64" 33/64" 37/64" | 0.272" 0.332" 0.397" 29/64" 33/64" 37/64" | 000000000 | 0000000 |

18-8 Stainless Steel with Thick Wall | ||||||

| 1/4"-20 Thread × 3/8" Installed Lg. (20 Each) 5/16"-18 Thread × 0.438" Installed Lg. (15 Each) 3/8"-16 Thread × 1/2" Installed Lg. (10 Each) 7/16"-14 Thread × 5/8" Installed Lg. (10 Each) 1/2"-13 Thread × 5/8" Installed Lg. (6 Each) 9/16"-12 Thread × 0.813" Installed Lg. (5 Each) 5/8"-11 Thread × 7/8" Installed Lg. (3 Each) 3/4"-10 Thread × 1 1/8" Installed Lg. (3 Each) 7/8"-9 Thread × 1 1/4" Installed Lg. (3 Each) 1"-8 Thread × 1 3/8" Installed Lg. (2 Each) Installation Tool | 77 | 7/16"-14 1/2"-13 9/16"-12 5/8"-11 3/4"-16 7/8"-14 1 1/8"-12 1 1/4"-12 1 3/8"-12 | X 29/64" 33/64" 37/64" 45/64" 53/64" 1 1/16" 1 3/16" 1 5/16" | 0.397" 29/64" 33/64" 37/64" 45/64" 53/64" 1 1/16" 1 3/16" 1 5/16" | 000000000 | 000000 |

Black-Phosphate Steel with Thin Wall | ||||||

| 10-24 Thread × 0.313" Installed Lg. (20 Each) 1/4"-20 Thread × 3/8" Installed Lg. (20 Each) 5/16"-18 Thread × 0.438" Installed Lg. (15 Each) 3/8"-16 Thread × 1/2" Installed Lg. (10 Each) 7/16"-14 Thread × 0.563" Installed Lg. (10 Each) 1/2"-13 Thread × 5/8" Installed Lg. (6 Each) Installation Tool | 81 | 5/16"-18 3/8"-16 7/16"-14 1/2"-13 9/16"-12 5/8"-11 | I Q X 29/64" 33/64" 37/64" | 0.272" 0.332" 0.397" 29/64" 33/64" 37/64" | 000000000 | 000000 |

Black-Phosphate Steel with Thick Wall | ||||||

| 1/4"-20 Thread × 3/8" Installed Lg. (20 Each) 5/16"-18 Thread × 0.438" Installed Lg. (15 Each) 3/8"-16 Thread × 1/2" Installed Lg. (10 Each) 7/16"-14 Thread × 5/8" Installed Lg. (10 Each) 1/2"-13 Thread × 5/8" Installed Lg. (6 Each) 9/16"-12 Thread × 0.813" Installed Lg. (5 Each) 5/8"-11 Thread × 7/8" Installed Lg. (3 Each) 3/4"-10 Thread × 1 1/8" Installed Lg. (3 Each) 7/8"-9 Thread × 1 1/4" Installed Lg. (3 Each) 1"-8 Thread × 1 3/8" Installed Lg. (2 Each) Installation Tool | 77 | 7/16"-14 1/2"-13 9/16"-12 5/8"-11 3/4"-16 7/8"-14 1 1/8"-12 1 1/4"-12 1 3/8"-12 | X 29/64" 33/64" 37/64" 45/64" 53/64" 1 1/16" 1 3/16" 1 5/16" | 0.397" 29/64" 33/64" 37/64" 45/64" 53/64" 1 1/16" 1 3/16" 1 5/16" | 000000000 | 000000 |

Screw-Locking Key-Locking Inserts

Forming the strongest hold of any of our threaded inserts, these inserts have a distorted internal thread to lock screws into place and keys that drive into surrounding material to prevent slipping and rotating. This creates a mechanical lock, which is stronger than the chemical lock from adhesive on thread-locking inserts. Because they’re made of a solid piece of metal, these inserts are also stronger than helical inserts, which are made of coiled wire. They're often used in molds, tools and dies, and suspension systems in vehicles to create completely new threads, add strong threads in soft metal, or replace existing threads that are damaged or need to be resized.

A dry-film lubricant makes it easy to install them and screw fasteners in. To install, use a tap to create the threads in your material and an installation tool to drive the keys into the material. All are made to tight tolerances with strictly controlled materials. Many inch sizes also meet military or aerospace standards for dimensions and material.

These inserts resist corrosion in wet environments. Cadmium-plated steel inserts are stronger than 18-8 stainless steel inserts.

Inserts with thin walls are best for small holes or near the edge of a workpiece. They’re often used in electronics that require small fasteners. Inserts with thick walls are most commonly used; they’re stronger than thin-wall inserts and are used in larger holes.

Inserts | Installation Tools | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | Specifications Met | Each | Each | ||

18-8 Stainless Steel with Thin Wall | ||||||||||

| 7/16"-14 | 9/16"-12 | 9/16" | 33/64" | 33/64" | 4 | MS51830-109L | 000000000 | 000000 | 000000000 | 000000 |

18-8 Stainless Steel with Thick Wall | ||||||||||

| 7/16"-14 | 5/8"-11 | 5/8" | 37/64" | 37/64" | 4 | MS51831-105L | 000000000 | 00000 | 000000000 | 00000 |

Cadmium-Plated Steel with Thick Wall | ||||||||||

| 7/16"-14 | 5/8"-11 | 5/8" | 37/64" | 37/64" | 4 | MS51831A105L | 000000000 | 00000 | 000000000 | 00000 |

Key-Locking Inserts with Installation Tool

Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. These inserts are used to repair or convert threads in soft metals such as aluminum. They’re comparable to Keensert® inserts.

18-8 stainless steel inserts are more corrosion resistant than black-phosphate steel. They may be mildly magnetic.

Black-phosphate steel inserts are mildly corrosion resistant.

Inserts with a thin wall are often used in small holes or near the edge of a workpiece.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | No. of Inserts Included | Each | |

18-8 Stainless Steel with Thin Wall | ||||||||

|---|---|---|---|---|---|---|---|---|

| 7/16"-14 | 9/16"-12 | 9/16" | 33/64" | 33/64" | 4 | 6 | 000000000 | 0000000 |

18-8 Stainless Steel with Thick Wall | ||||||||

| 7/16"-14 | 5/8"-11 | 5/8" | 37/64" | 37/64" | 4 | 6 | 000000000 | 00000 |

Black-Phosphate Steel with Thin Wall | ||||||||

| 7/16"-14 | 9/16"-12 | 9/16" | 33/64" | 33/64" | 4 | 6 | 000000000 | 00000 |

Black-Phosphate Steel with Thick Wall | ||||||||

| 7/16"-14 | 5/8"-11 | 5/8" | 37/64" | 37/64" | 4 | 6 | 000000000 | 00000 |

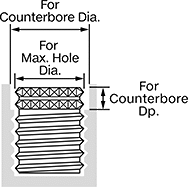

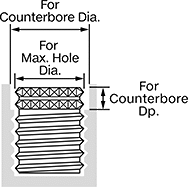

17-4 PH Stainless Steel Thin-Wall Swage-Locking Inserts

Position strong, corrosion-resistant threads close to the edges of soft metal surfaces. These inserts have thinner walls than our key-locking and thread-locking inserts, so they don’t need as much space around them. Even as you tighten or loosen a screw, these inserts won’t budge—their knurls press (swage) into the surrounding material to keep them in place. They’re made of 17-4 PH stainless steel, which has the strength of steel and the corrosion resistance of 18-8 stainless steel. Manufactured to tight tolerances, these inserts meet the strict standards of MIL-I-45932/1.

To install these inserts, you need a drill bit, a counterbore, a standard-sized tap, an installation tool, and a hammer. Drill a hole, counterbore the top, and tap it. Place the insert into the installation tool, then hand-tighten it into the tapped hole. Hammer away at the tool to secure the insert and drive the knurls into the surrounding material.

Alloy Steel Thin-Wall Swage-Locking Inserts

Add or repair threads near the edges and corners of soft metal surfaces—these inserts have thinner walls than any of our key-locking and thread-locking inserts. With knurls that press (swage) into the surrounding material, they won’t budge when you tighten a screw. Made of alloy steel, they’re stronger than our 17-4 PH stainless steel inserts. They absorb impact without fracturing and stand up to high-pressure applications. A cadmium plating keeps them from corroding in wet environments. On top of the plating is a dry film lubricant to help these inserts thread in without sticking. Meeting the strict standards for MIL-I-45932/1, these inserts have highly precise threads and tight tolerances.

To install these inserts, you need a drill bit, a counterbore, a standard-sized tap, an installation tool, and a hammer. Drill a hole, counterbore the top, then tap it. Place the insert into the installation tool and hand-tighten it into the tapped hole. Hammer the tool to secure the insert in place, driving the knurls into the surrounding material.

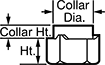

Steel Hex Weld Nuts

With three weld points, these hex weld nuts create a secure hold on steel surfaces. They stand up to high torque and pull force better than rivet and press-fit nuts, making them the strongest way to add permanent threads to sheet metal. You can also install them on thick pieces of metal. Made of uncoated steel, they require minimal prep for welding to uncoated steel surfaces. All have a collar pilot to guide the nut into the hole and hold it in place while welding. This also protects the threads from weld spatter.

All nuts meet ASME B1.1 and comply with specifications for dimensional standards.

Square Weld Nuts

Square weld nuts have more weld points than hex nuts for a stronger hold. Use them to add strong, permanent threads to uncoated steel surfaces. They stand up to more torque and pulling force than rivet nuts. These fasteners are uncoated, so they require minimal preparation before welding. All have a collar pilot that guides the nut into the hole, holds it in place while welding, and protects the threads from weld spatter.

Nuts that meet ASME B1.1 comply with specifications for dimensional standards.

Aligning Weld Nuts

Threads float inside the retainer so you can install a bolt at a slight angle to align with off-center parts. Weld these nuts to metal surfaces for a strong, permanent hold. They stand up to high torque and pulling force better than rivet nuts.

For the strongest threads, choose steel nuts. Nuts with a steel retainer should be welded to uncoated steel surfaces.

Base | |||||||

|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Wd. | Thick. | Ht. | Pkg. Qty. | Pkg. | |

Steel Nut with C1008/C1010 Steel Retainer | |||||||

| 7/16"-14 | 2 1/4" | 15/16" | 1/16" | 51/64" | 5 | 000000000 | 000000 |

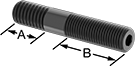

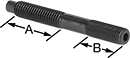

Hex Drive Threaded Rods

A hex drive on one end allows these rods to be turned with a hex key for ease of installation. Use them to connect parts with coarse threads to parts with fine threads. They're high-strength black-oxide steel and corrosion resistant in dry environments.

Rods with an unthreaded tip thread into nuts more easily, reducing the chance of damaging threads.

Thread (A) | Thread (B) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Size | Lg. | Size | Lg. | Lg. | Unthreaded Tip Lg. | Drive Size | Tensile Strength, psi | Hardness | Each | |

Black-Oxide Alloy Steel | ||||||||||

Threaded Tip | ||||||||||

| 7/16"-14 | 7/16" | 7/16"-20 | 1" | 2" | __ | 3/32" | 150,000 | Rockwell C39 | 000000000 | 00000 |

| 7/16"-14 | 3/4" | 7/16"-20 | 1" | 2 1/2" | __ | 3/16" | 150,000 | Rockwell C39 | 000000000 | 0000 |

| 7/16"-14 | 3/4" | 7/16"-20 | 1" | 2 3/4" | __ | 3/16" | 150,000 | Rockwell C39 | 000000000 | 0000 |

| 7/16"-14 | 3/4" | 7/16"-20 | 1" | 3 1/4" | __ | 3/16" | 150,000 | Rockwell C39 | 000000000 | 0000 |

| 7/16"-14 | 1" | 7/16"-20 | 1" | 3 1/2" | __ | 3/16" | 150,000 | Rockwell C39 | 000000000 | 0000 |

| 7/16"-14 | 1" | 7/16"-20 | 1" | 3 3/4" | __ | 3/16" | 150,000 | Rockwell C39 | 000000000 | 0000 |

| 7/16"-14 | 1" | 7/16"-20 | 1" | 4" | __ | 3/16" | 150,000 | Rockwell C39 | 000000000 | 0000 |

| 7/16"-14 | 1" | 7/16"-20 | 1" | 4 1/2" | __ | 3/16" | 150,000 | Rockwell C39 | 000000000 | 0000 |

Unthreaded Tip | ||||||||||

| 7/16"-14 | 1 7/16" | 7/16"-20 | 1" | 3 1/8" | 3/8" | 3/16" | 150,000 | Rockwell C39 | 000000000 | 0000 |

| 7/16"-14 | 1 5/8" | 7/16"-20 | 1 1/8" | 3 3/4" | 5/16" | 3/16" | 150,000 | Rockwell C39 | 000000000 | 00000 |

| 7/16"-14 | 1 5/8" | 7/16"-20 | 1 1/8" | 5 1/2" | 5/16" | 3/16" | 150,000 | Rockwell C39 | 000000000 | 00000 |

| 7/16"-14 | 1 5/8" | 7/16"-20 | 1 1/8" | 5 7/8" | 5/16" | 3/16" | 150,000 | Rockwell C39 | 000000000 | 00000 |

| 7/16"-14 | 1 5/8" | 7/16"-20 | 1 1/8" | 7" | 5/16" | 3/16" | 150,000 | Rockwell C39 | 000000000 | 00000 |

| 7/16"-14 | 1 5/8" | 7/16"-20 | 1 1/8" | 7 7/8" | 5/16" | 3/16" | 150,000 | Rockwell C39 | 000000000 | 00000 |

Threaded Adapters for Pullers

Use adapters on the ends of forcing screws and face-grip puller legs when pulling shafts, bearing caps, and pinions.

| Thread Size | Gender | Each | |

| 7/16"-14 × 5/8"-18 | Male × Female | 000000 | 000000 |