How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

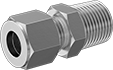

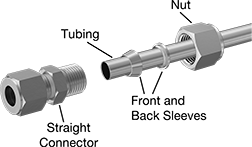

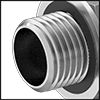

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

- For Use With:

Inch:

NPT and BSPT Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

BSPP Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Mineral Oil, Water

UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

Metric:

NPT, BSPT, and UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water - Tubing:

Inch:

NPT and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT, BSPT, and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

| 3mm | 0.5mm | 1/16 | 316 Stainless Steel | 9,700 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 3mm | 0.5mm | 1/8 | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3mm | 0.5mm | 1/4 | 316 Stainless Steel | 8,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3mm | 0.5mm | 3/8 | 316 Stainless Steel | 7,800 psi @ 72° F | -420° to 1200° | 0000000 | 00000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing:

Inch:

NPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

| 3mm | 0.5mm | 1/8 | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube (Metric) | For Tube (Inch) | |||||||

|---|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thick., mm | OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 3 | 0.8 | 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

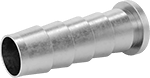

Fittings with tube stem insert into the tube end of another fitting in place of a length of tubing.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 3mm | 0.5mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With:

NPT and BSPT Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

BSPP Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Mineral Oil, Water

UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil - Tubing:

NPT and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

| 3mm | 0.5mm | 1/8 | 316 Stainless Steel | 6,500 psi @ 72° F | -420° to 1200° | 0000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 3mm | 0.5mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sleeves | |||||||||

| 1/8" | 0.035" | 316 Stainless Steel | 3/16" | 1 | 3/32" | 1 | 6,000 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.035" | 316 Stainless Steel | 3/16" | 1 | 3/32" | 1 | 4,000 psi @ 72° F | 00000000 | 0000 |

| 3mm | 0.5mm | 316 Stainless Steel | 5mm | 1 | 3mm | 1 | 4,000 psi @ 72° F | 00000000 | 0000 |

Sleeves with Dispenser | |||||||||

| 1/8" | 0.035" | 316 Stainless Steel | 3/16" | 10 | 3/32" | 10 | 6,000 psi @ 72° F | 00000000 | 00000 |

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each front sleeve, back sleeve, and nut is made of 316 stainless steel for excellent corrosion resistance. Five sets of sleeves and nuts come on each dispenser. Sleeves are also known as ferrules.

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Tube Support Style | Temp. Range, °F | Each | |

| 5/16" | 1/8" | 316 Stainless Steel | Barbed | -420° to 1200° | 00000000 | 00000 |

Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: See table

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are zinc-plated steel for fair corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 3mm | 0.8mm | Zinc-Plated Steel | 10,000 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 3mm | 0.8mm | Zinc-Plated Steel | 316 Stainless Steel | 10,000 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

Nuts for Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Mineral Oil, Fuel Oil, Gasoline, Diesel Fuel, Cutting Oil, Hydraulic Fluid

- Temperature Range: See table

- Tubing: Use with seamless steel

- Specifications Met: See table

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on steel tubing. They are zinc-plated steel for fair corrosion resistance.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 3mm | 0.8mm | Zinc-Plated Steel | 10,000 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

Front and Back Sleeves for Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Mineral Oil, Fuel Oil, Gasoline, Diesel Fuel, Cutting Oil, Hydraulic Fluid

- Temperature Range: -20° to 800° F

- Tubing: Use with seamless steel

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on steel tubing. They are also known as ferrules.

Zinc-plated steel sleeves have fair corrosion resistance. 316 stainless steel sleeves have excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Each | |

| 3mm | 0.8mm | Zinc-Plated Steel | 316 Stainless Steel | 10,000 psi @ 72° F | 00000000 | 00000 |

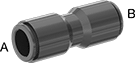

Push-to-Connect Tube Fittings for Air

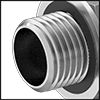

UN/UNF (SAE Straight)

Male Threads with Gasket

- Temperature Range: 0° to 170° F, except polybutylene plastic fittings are 32° to 140° F

- Tubing: Use with firm (Durometer 95A-45D) polyethylene plastic or polyurethane rubber

- Specifications Met: ISO 14743, except cartridges and polybutylene plastic fittings

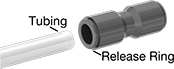

Insert tubing into these fittings and an internal gripping ring and O-ring hold the tubing tight. They are also known as instant fittings. To disconnect, push on the release ring and pull the tubing out of the fitting. Fittings have good corrosion resistance. Use them in low-pressure applications.

Identification rings (sold separately) snap over the release ring so you can color-code your lines.

Clips (sold separately) align and organize your tubing and fittings.

Metric male threads have either a gasket or a thread sealant to protect against leaks.

UN/UNF (SAE Straight)

Male Threads with Gasket

Fittings with tube stem insert into the push-to-connect end of another fitting in place of a length of tubing.

| Tube Stem OD | For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 4mm | 3mm | Nylon Plastic | Black | Black | 290 psi @ 72° F | 00000000 | 00000 |

| For Tube OD (A) | For Tube OD (B) | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 4mm | 3mm | Nylon Plastic | Black | Black | 290 psi @ 72° F | 00000000 | 000000 |

UN/UNF (SAE Straight)

Male Threads with Gasket

Fittings with external hex or slotted drive allow for easy adjustments in tight spaces; they are also known as banjo-style fittings.

| For Tube OD, mm | Thread Size | Thread Pitch, mm | Tube Connection Material | Pipe Connection Material | Gasket Material | Color | Release Ring Color | Max. Pressure | Each | |

Metric Threads | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3 | M3 | 0.5 | Nylon Plastic | Nickel-Plated Brass | Buna-N Rubber | Black | Black | 290 psi @ 72° F | 00000000 | 000000 |

UN/UNF (SAE Straight)

Male Threads with Gasket

Fittings with intermittent swivel rotate 360° before and after installation as needed to allow movement in the system and to prevent kinking.

| For Tube OD | Thread Size | Thread Pitch, mm | Tube Connection Material | Pipe Connection Material | Gasket Material | Color | Release Ring Color | Max. Pressure | Each | |

Metric Threads | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3mm | M3 | 0.5 | Nylon Plastic | Nickel-Plated Brass | Buna-N Rubber | Black | Black | 290 psi @ 72° F | 00000000 | 000000 |

| 3mm | M5 | 0.8 | Nylon Plastic | Nickel-Plated Brass | Buna-N Rubber | Black | Black | 290 psi @ 72° F | 00000000 | 00000 |

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 3mm | Nylon Plastic | Black | Black | 290 psi @ 72° F | 00000000 | 000000 |

Nickel-Plated Brass Push-to-Connect Tube Fittings for Air

(SAE Straight) Male

Threads with Gasket

- For Use With: Air, Lubricated Air

- Temperature Range: 0° to 140° F

- Tubing: Fittings with Release Ring and Fittings with no Release Type: Use with firm or hard (Durometer 95A-60D) nylon plastic, polyethylene plastic or polyurethane rubber

Fittings with Release Sleeve: Use with firm or hard (Durometer 95A-60D) polyethylene plastic or polyurethane rubber

Made of nickel-plated brass, these fittings have better corrosion resistance than unplated brass fittings. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring or sleeve and pull the tubing out of the fitting.

Fittings with release sleeve are easier to disconnect than fittings with a release ring because they are seamless and won't collect dirt and debris.

Metric and UN/UNF (SAE Straight) male threads with gasket or thread sealant provide extra protection against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

(SAE Straight) Male

Threads with Gasket

Release Sleeve | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Thread Size | Thread Pitch, mm | Material | Gasket Material | Max. Pressure | Each | |

Metric Threads | |||||||

| 3mm | M3 | 0.5 | Nickel-Plated Brass | Buna-N Rubber | 230 psi @ 72° F | 00000000 | 000000 |

| 3mm | M5 | 0.8 | Nickel-Plated Brass | Buna-N Rubber | 230 psi @ 72° F | 00000000 | 00000 |

UN/UNF (SAE Straight) Threads | |||||||

| 3mm | 10-32 | __ | Nickel-Plated Brass | Buna-N Rubber | 230 psi @ 72° F | 00000000 | 00000 |

Release Sleeve | ||||

|---|---|---|---|---|

| For Tube OD | Material | Max. Pressure | Each | |

| 3mm | Nickel-Plated Brass | 230 psi @ 72° F | 00000000 | 000000 |

(SAE Straight) Male

Threads with Gasket

Fittings with intermittent swivel rotate 360° before and after installation as needed to allow movement in the system and to prevent kinking.

Release Sleeve | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Thread Size | Thread Pitch, mm | Material | Gasket Material | Max. Pressure | Each | |

Metric Threads | |||||||

| 3mm | M3 | 0.5 | Nickel-Plated Brass | Buna-N Rubber | 230 psi @ 72° F | 00000000 | 000000 |

| 3mm | M5 | 0.8 | Nickel-Plated Brass | Buna-N Rubber | 230 psi @ 72° F | 00000000 | 00000 |

UN/UNF (SAE Straight) Threads | |||||||

| 3mm | 10-32 | __ | Nickel-Plated Brass | Buna-N Rubber | 230 psi @ 72° F | 00000000 | 00000 |

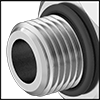

Universal-Thread Moisture-Resistant

Push-to-Connect Tube Fittings for Air and Water

Threads

with Gasket

- Temperature Range: 32° to 100° F

- Tubing: Use with firm (Durometer 90A-95A) nylon plastic or polyurethane rubber

The threads on these fittings mate with NPT, NPTF (Dryseal), BSPT, and BSPP threads. The male threads have a gasket to protect against leaks. Fittings are moisture and corrosion resistant, so they’re good for water and humid air applications. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting.

Static dissipative fittings divert static electricity.

Threads

with Gasket

Release Ring | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD, mm | Pipe Size | Tube Connection Material | Pipe Connection Material | Gasket Material | Material | Color | Max. Pressure | Each | |

| 3 | 1/8 | Brass | Nickel-Plated Brass | 304 Stainless Steel, Buna-N Rubber | Plastic | Black | 140 psi @ 72° F | 000000000 | 000000 |