Filter by

Screw Size

ID

OD

Thickness

Radius

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Mobility

Leveling Washers

Leveling Washers | Replacement Male Leveling Washers | Replacement Female Leveling Washers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Male | Female | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

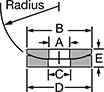

For Screw Size | ID (A) | OD (B) | Radius | ID (C) | OD (D) | Radius | Thk. (E) | Max. Angle of Correction | Hardness | Specs. Met | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.116" | 0.281" | 0.031" | 0.156" | 0.375" | — | 0.188" to 0.218" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.144" | 0.281" | 0.031" | 0.172" | 0.375" | — | 0.188" to 0.218" | 3° | Rockwell B80 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.169" | 0.313" | 0.031" | 0.188" | 0.375" | — | 0.188" to 0.218" | 3° | Rockwell B80 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.196" | 0.375" | 0.078" | 0.219" | 0.438" | — | 0.219" to 0.249" | 3° | Rockwell B80 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.257" | 0.438" | 0.109" | 0.281" | 0.500" | — | 0.251" to 0.281" | 3° | Rockwell B80 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.281" | 0.625" | 0.750" | 0.281" | 0.625" | 0.750" | 0.173" to 0.203" | 3° | Rockwell B80 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.323" | 0.500" | 0.063" | 0.344" | 0.563" | — | 0.312" to 0.344" | 3° | Rockwell B80 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.386" | 0.625" | 0.094" | 0.406" | 0.688" | — | 0.407" to 0.438" | 3° | Rockwell B80 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.406" | 0.875" | 1.250" | 0.438" | 0.875" | 1.250" | 0.235" to 0.265" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.468" | 1.000" | 1.500" | 0.500" | 1.000" | 1.500" | 0.297" to 0.327" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.531" | 1.125" | 1.500" | 0.531" | 1.125" | 1.500" | 0.298" to 0.328" | 2° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.656" | 1.375" | 1.750" | 0.656" | 1.375" | 1.750" | 0.298" to 0.328" | 2° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.781" | 1.625" | 2.250" | 0.781" | 1.625" | 2.250" | 0.360" to 0.390" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 0.937" | 1.750" | 2.500" | 0.968" | 1.750" | 2.500" | 0.360" to 0.390" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.062" | 2.000" | 2.750" | 1.093" | 2.000" | 2.750" | 0.485" to 0.515" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1.187" | 2.250" | 3.000" | 1.250" | 2.250" | 3.000" | 0.485" to 0.515" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.312" | 2.500" | 3.000" | 1.375" | 2.500" | 3.000" | 0.485" to 0.515" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.562" | 2.875" | 3.500" | 1.625" | 2.875" | 3.500" | 0.485" to 0.515" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 1.687" | 3.250" | 3.500" | 1.750" | 3.250" | 3.500" | 0.673" to 0.703" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 1.812" | 3.250" | 3.500" | 1.875" | 3.250" | 3.500" | 0.673" to 0.703" | 3° | Rockwell B80 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.062" | 3.875" | 3.500" | 2.125" | 3.875" | 3.500" | 0.735" to 0.765" | 3° | Rockwell B80 | — | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.2 mm | 9.5 mm | 7.0 mm | 3.6 mm | 9.5 mm | — | 3.2 mm to 3.8 mm | 3° | Rockwell B83 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 mm | 9.5 mm | 7.0 mm | 4.9 mm | 9.5 mm | — | 3.2 mm to 3.8 mm | 3° | Rockwell B83 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.3 mm | 11.1 mm | 7.5 mm | 6.0 mm | 11.1 mm | — | 3.7 mm to 4.3 mm | 3° | Rockwell B83 | — | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 mm | 12.0 mm | 9.0 mm | 7.1 mm | 12.0 mm | — | 3.8 mm to 4.4 mm | 3° | Not Rated | DIN 6319 | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.4 mm | 17.0 mm | 12.0 mm | 9.6 mm | 17.0 mm | — | 5.1 mm to 5.8 mm | 3° | Not Rated | DIN 6319 | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.5 mm | 21.0 mm | 15.0 mm | 12.0 mm | 21.0 mm | — | 6.1 mm to 6.7 mm | 3° | Not Rated | DIN 6319 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 13.0 mm | 24.0 mm | 17.0 mm | 14.2 mm | 24.0 mm | — | 7.7 mm to 8.2 mm | 3° | Not Rated | DIN 6319 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 17.0 mm | 30.0 mm | 22.0 mm | 19.0 mm | 30.0 mm | — | 9.1 mm to 9.8 mm | 3° | Not Rated | DIN 6319 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 21.0 mm | 36.0 mm | 27.0 mm | 23.2 mm | 36.0 mm | — | 11.4 mm to 11.9 mm | 3° | Not Rated | DIN 6319 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 mm | 44.0 mm | 32.0 mm | 28.0 mm | 44.0 mm | — | 14.7 mm to 15.4 mm | 3° | Not Rated | DIN 6319 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 | 31.0 mm | 56.0 mm | 41.0 mm | 35.0 mm | 56.0 mm | — | 18.6 mm to 19.4 mm | 3° | Not Rated | DIN 6319 | 000000000 | 000000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 mm | 12.0 mm | 9.0 mm | 7.1 mm | 12.0 mm | — | 3.8 mm to 4.4 mm | 3° | Rockwell C52 | DIN 6319 | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.4 mm | 17.0 mm | 12.0 mm | 9.6 mm | 17.0 mm | — | 5.1 mm to 5.8 mm | 3° | Rockwell C52 | DIN 6319 | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.5 mm | 21.0 mm | 15.0 mm | 12.0 mm | 21.0 mm | — | 6.1 mm to 6.7 mm | 3° | Rockwell C52 | DIN 6319 | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 13.0 mm | 24.0 mm | 17.0 mm | 14.2 mm | 24.0 mm | — | 7.7 mm to 8.2 mm | 3° | Rockwell C52 | DIN 6319 | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 17.0 mm | 30.0 mm | 22.0 mm | 19.0 mm | 30.0 mm | — | 9.1 mm to 9.8 mm | 3° | Rockwell C52 | DIN 6319 | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 21.0 mm | 36.0 mm | 27.0 mm | 23.2 mm | 36.0 mm | — | 11.4 mm to 11.9 mm | 3° | Rockwell C52 | DIN 6319 | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 25.0 mm | 44.0 mm | 32.0 mm | 28.0 mm | 44.0 mm | — | 14.7 mm to 15.4 mm | 3° | Rockwell C52 | DIN 6319 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 | 31.0 mm | 56.0 mm | 41.0 mm | 35.0 mm | 56.0 mm | — | 18.6 mm to 19.4 mm | 3° | Rockwell C52 | DIN 6319 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.116" | 0.281" | 0.031" | 0.156" | 0.375" | — | 0.188" to 0.218" | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.144" | 0.281" | 0.031" | 0.172" | 0.375" | — | 0.188" to 0.218" | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.169" | 0.313" | 0.031" | 0.188" | 0.375" | — | 0.188" to 0.218" | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.196" | 0.375" | 0.078" | 0.219" | 0.438" | — | 0.219" to 0.249" | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.257" | 0.438" | 0.109" | 0.281" | 0.500" | — | 0.251" to 0.281" | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.281" | 0.625" | 0.750" | 0.281" | 0.625" | 0.750" | 0.173" to 0.203" | 3° | Rockwell C25 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.323" | 0.500" | 0.063" | 0.344" | 0.563" | — | 0.312" to 0.344" | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.386" | 0.625" | 0.094" | 0.406" | 0.688" | — | 0.407" to 0.438" | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.406" | 0.875" | 1.250" | 0.438" | 0.875" | 1.250" | 0.235" to 0.265" | 3° | Rockwell C25 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.468" | 1.000" | 1.500" | 0.500" | 1.000" | 1.500" | 0.297" to 0.327" | 3° | Rockwell C25 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.531" | 1.125" | 1.500" | 0.531" | 1.125" | 1.500" | 0.298" to 0.328" | 2° | Rockwell C25 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.656" | 1.375" | 1.750" | 0.656" | 1.375" | 1.750" | 0.298" to 0.328" | 2° | Rockwell C25 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.781" | 1.625" | 2.250" | 0.781" | 1.625" | 2.250" | 0.360" to 0.390" | 3° | Rockwell C25 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 0.938" | 1.750" | 2.500" | 0.969" | 1.750" | 2.500" | 0.360" to 0.390" | 3° | Rockwell C25 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.062" | 2.000" | 2.750" | 1.094" | 2.000" | 2.750" | 0.485" to 0.515" | 3° | Rockwell C25 | — | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1.188" | 2.250" | 3.000" | 1.250" | 2.250" | 3.000" | 0.485" to 0.515" | 3° | Rockwell C25 | — | 000000000 | 00000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.312" | 2.500" | 3.000" | 1.375" | 2.500" | 3.000" | 0.485" to 0.515" | 3° | Rockwell C25 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.562" | 2.875" | 3.000" | 1.625" | 2.875" | 3.000" | 0.485" to 0.515" | 3° | Rockwell C25 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 1.687" | 3.250" | 3.500" | 1.750" | 3.250" | 3.500" | 0.673" to 0.703" | 3° | Rockwell C48 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 1.812" | 3.250" | 3.500" | 1.875" | 3.250" | 3.500" | 0.673" to 0.703" | 3° | Rockwell C48 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.062" | 3.875" | 3.500" | 2.125" | 3.875" | 3.500" | 0.735" to 0.765" | 3° | Rockwell C48 | — | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.2 mm | 9.5 mm | 7.0 mm | 3.6 mm | 9.5 mm | — | 3.2 mm to 3.8 mm | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 mm | 9.5 mm | 7.0 mm | 4.9 mm | 9.5 mm | — | 3.2 mm to 3.8 mm | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.3 mm | 11.1 mm | 7.5 mm | 6.0 mm | 11.1 mm | — | 3.7 mm to 4.3 mm | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 | 15.0 mm | 28.5 mm | 20.0 mm | 16.5 mm | 28.5 mm | — | 8.2 mm to 8.8 mm | 3° | Rockwell C48 | — | 000000000 | 0000 | 000000000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot-Water Pressure Washers

|  |  |

Style A | Style B | Style C |

Style A

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Adjustability | Max. Continuous Usage, hr. | Max. Pressure, psi | Flow Rate, gpm | Power, hp | Max. Water Temp., ° F | Ht. | Wd. | Dp. | Frame Material | NEMA Type | Current, amp | No. of Spray Nozzles | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Adjustable | 8 | 1,200 | 1.7 | 2.3 | 175 | 39" | 24" | 24" | Plastic | 5-15 | 12.5 | 1 | Canada | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style B

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Adjustability | Max. Continuous Usage, hr. | Max. Pressure, psi | Flow Rate, gpm | Power, hp | Max. Water Temp., ° F | Ht. | Wd. | Dp. | Frame Material | NEMA Type | Current, amp | No. of Spray Nozzles | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Adjustable | 8 | 2,000 | 3.5 | 5 | 180 | 44" | 27" | 39" | Steel | 6-30 | 22 | 3 | Canada | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Adjustability | Max. Continuous Usage, hr. | Max. Pressure, psi | Flow Rate, gpm | Power, hp | Max. Water Temp., ° F | Ht. | Wd. | Dp. | Frame Material | No. of Spray Nozzles | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gasoline Powered | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Adjustable | 8 | 3,500 | 3.5 | 13 | 180 | 44" | 28" | 46" | Steel | 3 | Canada | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure Washers

|  |

Style A | Style B |

|  |

Style C | Style F |

Style A

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Adjustability | Max. Continuous Usage, hr. | Max. Pressure, psi | Flow Rate, gpm | Power, hp | Max. Inlet Water Temp., ° F | Ht. | Wd. | Dp. | Frame Material | NEMA Type | Current, amp | No. of Spray Nozzles | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC Single Phase—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Adjustable | 4 | 1,400 | 1.5 | 1 1/2 | 100 | 10" | 11" | 14" | Plastic | 5-15 | 13.5 | 1 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Adjustable | 8 | 1,500 | 2 | 2 | 125 | 14" | 12" | 20" | Steel | 5-20 | 17 | 1 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style B

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Adjustability | Max. Continuous Usage, hr. | Max. Pressure, psi | Flow Rate, gpm | Power, hp | Max. Inlet Water Temp., ° F | Ht. | Wd. | Dp. | Frame Material | NEMA Type | Current, amp | No. of Spray Nozzles | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC Single Phase—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Adjustable | 8 | 1,000 | 2.2 | 1 1/2 | 160 | 31" | 23" | 16" | Stainless Steel | 5-15 | 15 | 5 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

208V AC/240V AC Three Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Adjustable | 8 | 2,000 | 4 | 5 | 160 | 30" | 28" | 22" | Stainless Steel | — | 15 | 5 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Adjustability | Max. Continuous Usage, hr. | Max. Pressure, psi | Flow Rate, gpm | Power, hp | Max. Inlet Water Temp., ° F | Ht. | Wd. | Dp. | Frame Material | NEMA Type | Current, amp | No. of Spray Nozzles | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC Single Phase—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Adjustable | 8 | 1,500 | 2 | 2 | 125 | 24 1/2" | 21" | 37" | Steel | 5-20 | 17 | 1 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style F

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Adjustability | Max. Continuous Usage, hr. | Max. Pressure, psi | Flow Rate, gpm | Power, hp | Max. Inlet Water Temp., ° F | Ht. | Wd. | Dp. | Frame Material | No. of Spray Nozzles | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gasoline Powered | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Adjustable | 8 | 3,500 | 3.7 | 13 | 140 | 30" | 26" | 42" | Steel | 5 | Canada | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

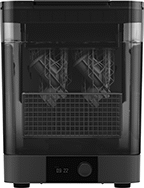

Automated 3D-Printed-Parts Washers

For Max. Part | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Voltage, V AC | Material | Electrical Connection Type | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Soak/Agitate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2 | 7 7/8" | 5 5/8" | 7 1/2" | 12 3/8" | 11 1/2" | 15 7/8" | 120, 240 | Plastic | Plug In | Adjustable Mounting Feet, Density Meter, Wash Tub | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Parts Washers for Solvent-Based Solutions

Usable Tub | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Cap., gal. | Max. Liquid Level | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Voltage, V AC | Material | Electrical Connection Type | Specs. Met | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Soak/Spray/Agitate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 42 | 10" | 32 1/2" | 19 1/2" | 23 1/2" | 44" | 22" | 39 1/2" | 120 | Steel | Plug In | UL 1204 | Flexible Spigot, Drain Plug, Safety Cover with Fusible Link, Two Bi-Level Parts Shelves, Filter, Hose with Spray Nozzle, Agitator | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 85 | 15" | 30" | 28" | 29 1/2" | 41 1/2" | 30 1/2" | 39 1/2" | 120 | Steel | Plug In | UL 1204 | Flexible Spigot, Drain Plug, Safety Cover with Fusible Link, Two Bi-Level Parts Shelves, Filter, Hose with Spray Nozzle, Agitator | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||