About Air Preparation

More

About Air Compressors

More

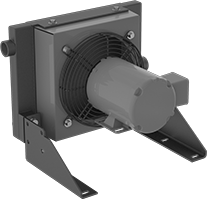

Fan-Cooled Compressed Air Aftercoolers

These aftercoolers have a fan that chills hot air coming from a compressor. Cooling the air condenses water for removal from your compressed air system. Install a separator (not included) after your aftercooler to collect and discharge water.

Air Inlet | Air Outlet | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Max. Pressure, psi | Max. Flow Rate @ psi | Max. Temp., °F | Cools Air Within | Ht. | Wd. | Dp. | hp | Each | |

Ceiling-, Floor-, and Wall-Mount | |||||||||||||||

Single Phase, 115-230V AC | |||||||||||||||

| 1 | NPT | Female | 1 | NPT | Female | 250 | 50 scfm @ 80 | 350° | 15° F of Ambient Air | 12 7/8" | 19 1/2" | 13 3/4" | 1/3 | 0000000 | 000000000 |

| 1 1/2 | NPT | Female | 1 1/2 | NPT | Female | 250 | 100 scfm @ 80 | 350° | 15° F of Ambient Air | 13 1/4" | 19 1/2" | 15 1/8" | 1/3 | 0000000 | 00000000 |

| 1 1/2 | NPT | Female | 1 1/2 | NPT | Female | 250 | 200 scfm @ 80 | 350° | 15° F of Ambient Air | 17 1/4" | 23 1/4" | 16 1/4" | 1/2 | 0000000 | 00000000 |

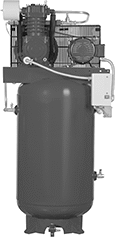

Electric Air Compressors with Aftercooler

Power equipment with built-in moisture control—these air compressors have a built-in aftercooler that cools down air leaving the compressor to remove condensation. This helps relieve the strain on your separator and dryer down the line. These compressors are useful for air-powered tools, where corrosion can clog air lines, and for control systems, where moisture can disrupt signals.

These compressors use pistons to pressurize air in two stages—compressing air, cooling it, and then compressing it again. This two-step process reduces wear, limits heat buildup, and improves overall efficiency. The integrated aftercooler cools the air as it exits the compressor, condensing any remaining moisture so it can be drained before it causes an issue. The automatic drain clears the condensate from the tank to keep everything running smoothly—especially important in high-moisture lines.

These compressors turn on when tank pressure drops to the actuation point and shut off when it reaches maximum pressure. They can run continuously without a cooling period. If you plan to run them continuously, use SAE 30 synthetic oil (sold separately) to maintain performance and efficiency.

Air Compressors | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure, psi | Outlet (Female) | Overall | Oil | Replacement Filter Elements | Replacement Drive Belts | |||||||||||||||||

| Max. | Actuation | Max. Flow Rate @ psi | hp | Full Load Current, A | Tank Cap., gal. | Volume, dBA | Pipe Size | Thread Type | Lg. | Wd. | Ht. | Mounting Orientation | Includes | Each | Container Size, qt. | Each | Each | Each | ||||

Single Phase, 230V AC | ||||||||||||||||||||||

| 175 | 135 | 23.6 cfm @ 175 24.3 cfm @ 100 | 7 1/2 | 28.6 | 80 | 78 | 3/4 | NPT | 35" | 28" | 77" | Vertical | Aftercooler, Lubricant, Shutdown Switch, Tank Pressure Gauge | 00000000 | 000000000 | 1 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 |

Three Phase, 230V AC | ||||||||||||||||||||||

| 175 | 135 | 23.6 cfm @ 175 24.3 cfm @ 100 | 7 1/2 | 19.6 | 80 | 78 | 3/4 | NPT | 35" | 28" | 77" | Vertical | Aftercooler, Lubricant, Shutdown Switch, Tank Pressure Gauge | 00000000 | 00000000 | 1 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 |

Three Phase, 460V AC | ||||||||||||||||||||||

| 175 | 135 | 23.6 cfm @ 175 24.3 cfm @ 100 | 7 1/2 | 9.8 | 80 | 78 | 3/4 | NPT | 35" | 28" | 77" | Vertical | Aftercooler, Lubricant, Shutdown Switch, Tank Pressure Gauge | 00000000 | 00000000 | 1 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 |