Select a cylinder, prolong its life by reducing wear, and trigger automated processes with sensors.

Flexible-Mount ISO Air Cylinders

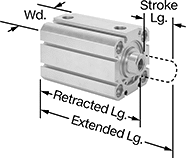

For multiple mounting options, these air cylinders match an industry standard ISO footprint and have threaded holes on the face and sides. Their ISO footprint makes it easy to change out an old air cylinder. To mount them directly to equipment or add on attachments, use the threaded through holes. These cylinders are double acting, so they push and pull loads with equal force.

The piston is magnetic, so you can use these cylinders with sensors (not included) to activate relays and controllers. When the piston moves past a sensor, the sensor activates. You can use multiple sensors—one for each action you want to trigger.

For technical drawings and 3-D models, click on a part number.

Air Cylinders | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Air Inlet | Sensors | ||||||||||

| Stroke, mm | Retracted, mm | Extended, mm | Force @ 100 psi, lbs. | Body Material | Pipe Size | Thread Size | Thread Type | Gender | Each | Each | ||

20 mm Bore Size (36 mm Wd.) | ||||||||||||

| 10 | 53 | 63 | 49 | Aluminum | __ | M5 × 0.8 mm | Metric | Female | 0000000 | 000000 | 00000000 | 000000 |

| 25 | 68 | 93 | 49 | Aluminum | __ | M5 × 0.8 mm | Metric | Female | 0000000 | 00000 | 00000000 | 00000 |

| 50 | 93 | 143 | 49 | Aluminum | __ | M5 × 0.8 mm | Metric | Female | 0000000 | 00000 | 00000000 | 00000 |

| 80 | 123 | 203 | 49 | Aluminum | __ | M5 × 0.8 mm | Metric | Female | 0000000 | 00000 | 00000000 | 00000 |

25 mm Bore Size (40 mm Wd.) | ||||||||||||

| 25 | 70 | 95 | 77 | Aluminum | __ | M5 × 0.8 mm | Metric | Female | 0000000 | 00000 | 00000000 | 00000 |

| 50 | 95 | 145 | 77 | Aluminum | __ | M5 × 0.8 mm | Metric | Female | 0000000 | 00000 | 00000000 | 00000 |

| 80 | 125 | 205 | 75 | Aluminum | __ | M5 × 0.8 mm | Metric | Female | 0000000 | 00000 | 00000000 | 00000 |

| 100 | 145 | 245 | 75 | Aluminum | __ | M5 × 0.8 mm | Metric | Female | 0000000 | 00000 | 00000000 | 00000 |

32 mm Bore Size (46 mm Wd.) | ||||||||||||

| 25 | 76 | 101 | 126 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 00000 | 00000000 | 00000 |

32 mm Bore Size (48 mm Wd.) | ||||||||||||

| 50 | 101 | 151 | 124 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 00000 | 00000000 | 00000 |

| 80 | 131 | 211 | 124 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 00000 | 00000000 | 00000 |

| 100 | 151 | 251 | 124 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 00000 | 00000000 | 00000 |

50 mm Bore Size (68 mm Wd.) | ||||||||||||

| 25 | 78 | 103 | 303 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 000000 | 00000000 | 00000 |

| 50 | 103 | 153 | 303 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 000000 | 00000000 | 00000 |

| 80 | 133 | 213 | 303 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 000000 | 00000000 | 00000 |

| 100 | 153 | 253 | 303 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 000000 | 00000000 | 00000 |

63 mm Bore Size (78 mm Wd.) | ||||||||||||

| 25 | 82 | 107 | 482 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 000000 | 00000000 | 00000 |

| 50 | 107 | 157 | 482 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 000000 | 00000000 | 00000 |

| 80 | 137 | 217 | 482 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 000000 | 00000000 | 00000 |

| 100 | 157 | 257 | 482 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 000000 | 00000000 | 00000 |

Base Mounting Holes | Top Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Wd., mm | Ht., mm | Dp., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Material | Each | |

| 20 | 23 | 22 | 36 | 4 | 2 | 7 | 22 | No | 2 | 6 | 22 | Yes | Zinc-Plated Steel | 00000000 | 00000 |

| 25 | 23 | 22 | 40 | 4 | 2 | 7 | 26 | No | 2 | 6 | 26 | Yes | Zinc-Plated Steel | 00000000 | 0000 |

| 32 | 35 | 26 | 45 | 4 | 2 | 7 | 32 | No | 2 | 7 | 32.5 | Yes | Zinc-Plated Steel | 00000000 | 00000 |

| 50 | 47 | 35 | 65 | 5 | 2 | 9 | 45 | No | 2 | 9 | 46.5 | Yes | Zinc-Plated Steel | 00000000 | 00000 |

| 63 | 47 | 35 | 75 | 5 | 2 | 9 | 50 | No | 2 | 9 | 56.5 | Yes | Zinc-Plated Steel | 00000000 | 00000 |

Inside Mounting Holes | Outside Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Wd., mm | Ht., mm | Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Material | Each | |

| 20 | 38 | 68 | 8 | 4 | 6 | 22 | Yes | 2 | 7 | 55 | No | Anodized Aluminum | 00000000 | 000000 |

| 25 | 38 | 73 | 8 | 4 | 6 | 26 | Yes | 2 | 7 | 60 | No | Anodized Aluminum | 00000000 | 00000 |

| 32 | 50 | 80 | 10 | 4 | 7 | 35.5 | Yes | 4 | 7 | 64 | No | Zinc-Plated Steel | 00000000 | 00000 |

| 50 | 65 | 110 | 12 | 4 | 9 | 46.5 | Yes | 4 | 9 | 90 | No | Zinc-Plated Steel | 00000000 | 00000 |

| 63 | 75 | 120 | 12 | 4 | 9 | 56.5 | Yes | 4 | 9 | 100 | No | Zinc-Plated Steel | 00000000 | 00000 |

Pin | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Dia., mm | Material | Wd., mm | Ht., mm | Dp., mm | Jaw Opening Wd., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Material | Includes | Each | |

| 32 | 10 | Steel | 45 | 45 | 32 | 26 | 10 | 4 | 7 | 32.5 | Yes | Zinc-Plated Steel | Four Washers, Two Snap Rings, One Pin | 00000000 | 000000 |

| 50 | 12 | Steel | 65 | 65 | 40 | 32 | 12 | 4 | 9 | 46.5 | Yes | Zinc-Plated Steel | Four Washers, Two Snap Rings, One Pin | 00000000 | 00000 |

| 63 | 16 | Steel | 75 | 75 | 50 | 40 | 12 | 4 | 9 | 56.5 | Yes | Zinc-Plated Steel | Four Washers, Two Snap Rings, One Pin | 00000000 | 00000 |

| For Bore Size, mm | Includes | Each | |

| 20 | Piston Seal, Rod Seal, Tube Gasket | 00000000 | 00000 |

| 25 | Piston Seal, Rod Seal, Tube Gasket | 00000000 | 0000 |

| 25 | Piston Seal, Rod Seal, Rod Wiper, Two Tube Seals | 00000000 | 0000 |

| 32 | Piston Seal, Rod Seal, Tube Gasket | 00000000 | 0000 |

| 32 | Piston Seal, Rod Seal, Rod Wiper, Two Tube Seals | 00000000 | 00000 |

| 50 | Piston Seal, Rod Seal, Rod Wiper, Two Tube Seals | 00000000 | 00000 |

| 63 | Piston Seal, Rod Seal, Rod Wiper, Two Tube Seals | 00000000 | 00000 |

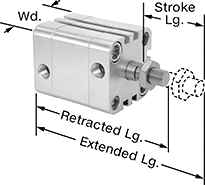

Clean Room Flexible-Mount Air Cylinders

Mount these cylinders directly to equipment in environments where contamination is a concern, such as electronics manufacturing. Use the threaded through-holes on the face to connect to equipment, or mount them with attachments (not included). Hook these cylinders into your compressed air line to push and pull loads. They’re double-acting, so they operate at full force in either direction. The magnetic piston inside these cylinders can activate relays and controllers when used with a sensor (not included). As the piston moves past the sensor, the sensor activates. You can use multiple sensors—attach one for each action you want to trigger.

Cylinders that are rated for use in Fed. Std. Class 1,000 and ISO Class 6 clean rooms have a low-friction polyurethane seal that wears slower and creates fewer particles than standard seals. As the rod moves, the seal wipes its surface clean of grease particles. The end caps are tightly crimped to stop air from leaking out. These cylinders have an ISO industry-standard footprint that fits common mounting patterns.

For technical drawings and 3-D models, click on a part number.

Lg., mm | Air Inlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke | Retracted | Extended | Force @ 100 psi, lbs. | Environmental Rating | Air Cushion Type | Body Material | Pipe Size | Thread Size | Thread Type | Gender | Specifications Met | Each | |

Sensor Ready | |||||||||||||

25 mm Bore Size (40 mm Wd.) | |||||||||||||

| 10 | 71 | 65 | 76 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | __ | M5 × 0.8 mm | Metric | Female | ISO 21287 | 0000000 | 000000 |

| 15 | 76 | 75 | 76 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | __ | M5 × 0.8 mm | Metric | Female | ISO 21287 | 0000000 | 00000 |

| 20 | 81 | 85 | 76 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | __ | M5 × 0.8 mm | Metric | Female | ISO 21287 | 0000000 | 00000 |

| 25 | 70 | 95 | 76 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | __ | M5 × 0.8 mm | Metric | Female | ISO 21287 | 0000000 | 00000 |

32 mm Bore Size (47 mm Wd.) | |||||||||||||

| 10 | 60 | 70 | 124 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | 1/8 | __ | BSPP | Female | ISO 21287 | 0000000 | 00000 |

| 15 | 65 | 80 | 124 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | 1/8 | __ | BSPP | Female | ISO 21287 | 0000000 | 00000 |

| 20 | 70 | 90 | 124 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | 1/8 | __ | BSPP | Female | ISO 21287 | 0000000 | 00000 |

| 25 | 75 | 100 | 124 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | 1/8 | __ | BSPP | Female | ISO 21287 | 0000000 | 00000 |

40 mm Bore Size (55 mm Wd.) | |||||||||||||

| 10 | 61 | 71 | 194 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | 1/8 | __ | BSPP | Female | ISO 21287 | 0000000 | 000000 |

| 15 | 66 | 81 | 194 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | 1/8 | __ | BSPP | Female | ISO 21287 | 0000000 | 000000 |

| 20 | 71 | 91 | 194 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | 1/8 | __ | BSPP | Female | ISO 21287 | 0000000 | 000000 |

| 25 | 76 | 101 | 194 | Fed. Std. Class 1,000, ISO Class 6 | Fixed Cushion | Aluminum | 1/8 | __ | BSPP | Female | ISO 21287 | 0000000 | 000000 |

Base Mounting Holes | Top Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Wd., mm | Ht., mm | Dp., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Material | Each | |

| 25 | 23 | 22 | 40 | 4 | 2 | 7 | 26 | No | 2 | 6 | 26 | Yes | Zinc-Plated Steel | 00000000 | 00000 |

Connect these mounts to an air cylinder to create linear, pivot, or arc movements. These mounts are compatible with ISO tie rod air cylinders.

Front or rear flanges are for straightforward, back-and-forth movements, such as opening a sliding door. These flanges mount to either end of your cylinder.

Pivot brackets and clevis brackets work together to allow the rear portion of cylinders to pivot back and forth. Use either with a rod clevis to create arcing movements, such as opening a swinging door. Rod clevises allow the front portion of cylinders to pivot.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.