Select a cylinder, prolong its life by reducing wear, and trigger automated processes with sensors.

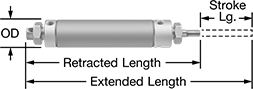

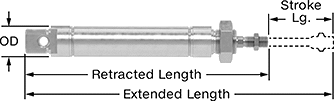

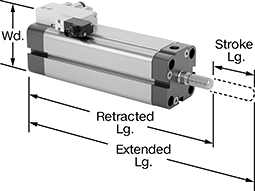

Double-Acting Round Body Air Cylinders

Push and pull light duty loads. These air cylinders use compressed air to both extend and retract, so they operate at nearly full force in either direction. They have a round body—the most common style of air cylinder—making them more compact and better suited for tight spaces than cylinders with external tie rods.

Universal-mount cylinders have mounting threads on both ends. The back end has a pivot bushing, which allows for more mounting options than nose-mount cylinders. Nose-mount cylinders only have mounting threads on the front end, so they’re shorter than universal-mount cylinders.

Sensor-ready cylinders have a magnetic piston that can activate relays and controllers when used with a sensor (sold separately). When the piston moves past the sensor, the sensor activates. You can use multiple sensors—attach one for each action to trigger.

Cylinders with an adjustable cushion absorb piston impact to minimize wear and noise. Turn the screws to adjust the level of cushioning.

For technical drawings and 3-D models, click on a part number.

Lg. | Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke | Retracted | Extended | Force @ 100 psi, lbs. | Sensor Ready | Air Cushion Type | Body Material | Pipe Size | Thread Size | Thread Type | Gender | Each | |

16mm Bore Size (18mm OD) | ||||||||||||

| 80mm | 188mm | 268mm | 31 | Not Sensor Ready | No Cushion | 304 Stainless Steel | __ | M5 × 0.8 | Metric | Female | 00000000 | 000000 |

| 80mm | 188mm | 268mm | 31 | Sensor Ready | No Cushion | 304 Stainless Steel | __ | M5 × 0.8 | Metric | Female | 00000000 | 000000 |

20mm Bore Size (24mm OD) | ||||||||||||

| 80mm | 206mm | 286mm | 48 | Not Sensor Ready | No Cushion | 304 Stainless Steel | 1/8 | __ | BSPP | Female | 00000000 | 000000 |

| 80mm | 206mm | 286mm | 48 | Sensor Ready | No Cushion | 304 Stainless Steel | 1/8 | __ | BSPP | Female | 00000000 | 000000 |

| 80mm | 206mm | 286mm | 49 | Not Sensor Ready | Adjustable Cushion | 304 Stainless Steel | 1/8 | __ | BSPP | Female | 00000000 | 000000 |

25mm Bore Size (27mm OD) | ||||||||||||

| 80mm | 217mm | 297mm | 76 | Not Sensor Ready | No Cushion | 304 Stainless Steel | 1/8 | __ | BSPP | Female | 00000000 | 000000 |

| 80mm | 217mm | 297mm | 76 | Not Sensor Ready | Adjustable Cushion | 304 Stainless Steel | 1/8 | __ | BSPP | Female | 00000000 | 000000 |

| 80mm | 217mm | 297mm | 76 | Sensor Ready | No Cushion | 304 Stainless Steel | 1/8 | __ | BSPP | Female | 00000000 | 000000 |

Instead of attaching your round body air cylinder directly to equipment, add a mount to best suit your application.

Foot brackets prevent cylinders from moving back and forth.

Pivot brackets for universal-mount air cylinders allow the rear portion of cylinders to pivot back and forth.

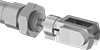

Rod clevises thread to cylinder shafts to allow swiveling.

Rod ends are internally threaded. They have an eyelet and ball that swivel to support angular misalignment and allow for pivoting.

Rod end nuts are internally threaded. They have an eyelet to make pivoting and hinge movements.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.

Instead of attaching your round body air cylinder directly to equipment, add a mount to best suit your application.

Foot brackets prevent cylinders from moving back and forth.

Pivot brackets for universal-mount air cylinders allow the rear portion of cylinders to pivot back and forth.

Rod clevises thread to cylinder shafts to allow swiveling.

Rod ends are internally threaded. They have an eyelet and ball that swivel to support angular misalignment and allow for pivoting.

Rod end nuts are internally threaded. They have an eyelet to make pivoting and hinge movements.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.

Instead of attaching your round body air cylinder directly to equipment, add a mount to best suit your application.

Foot brackets prevent cylinders from moving back and forth.

Pivot brackets for universal-mount air cylinders allow the rear portion of cylinders to pivot back and forth.

Rod clevises thread to cylinder shafts to allow swiveling.

Rod ends are internally threaded. They have an eyelet and ball that swivel to support angular misalignment and allow for pivoting.

Rod end nuts are internally threaded. They have an eyelet to make pivoting and hinge movements.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.

Instead of attaching your round body air cylinder directly to equipment, add a mount to best suit your application.

Foot brackets prevent cylinders from moving back and forth.

Pivot brackets for universal-mount air cylinders allow the rear portion of cylinders to pivot back and forth.

Rod clevises thread to cylinder shafts to allow swiveling.

Rod ends are internally threaded. They have an eyelet and ball that swivel to support angular misalignment and allow for pivoting.

Rod end nuts are internally threaded. They have an eyelet to make pivoting and hinge movements.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.

Clean Room Round Body Air Cylinders

Minimize the release of particles that can damage electronics or contaminate batches as you push and pull light loads. These air cylinders are designed with seals and caps that prevent particles from escaping. A rod seal wipes grease particles off the rod as it moves back and forth. The seal is polyurethane, which is slippery, so it wears more slowly than standard seals, releasing fewer particles. These cylinders also have tightly crimped end caps to stop air from leaking.

With no tie rods on the outside, these round-body cylinders fit in tight spaces. They have an ISO industry-standard footprint that fits common mounting patterns for easy interchangeability. As universal-mount cylinders, they have mounting threads on both ends, giving you more mounting options than nose-mount cylinders. You can also pivot mount them with the through-hole on the back. They’re double acting, meaning they push and pull loads with equal force.

The piston is magnetic, so you can use these cylinders with sensors (sold separately) to activate relays and controllers. When the piston moves past a sensor, the sensor activates. You can use multiple sensors—one for each action you want to trigger.

For technical drawings and 3-D models, click on a part number.

Lg., mm | Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke | Retracted | Extended | Force @ 100 psi, lbs. | Environmental Rating | Air Cushion Type | Body Material | Rod Thread Size | Pipe Size | Thread Type | Gender | Each | |

32mm Bore Size (42mm OD) | ||||||||||||

| 80 | 231.5 | 311.5 | 124 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M10 × 1.25 mm | 1/8 | BSPP | Female | 0000000 | 0000000 |

40mm Bore Size (50mm OD) | ||||||||||||

| 80 | 257.6 | 337.6 | 194 | Fed. Std. Class 1,000, ISO Class 6 | Self Adjusting | Aluminum | M12 × 1.25 mm | 1/4 | BSPP | Female | 0000000 | 000000 |

Instead of attaching your round body air cylinder directly to equipment, add a mount to best suit your application.

Foot brackets prevent cylinders from moving back and forth.

Pivot brackets for universal-mount air cylinders allow the rear portion of cylinders to pivot back and forth.

Rod clevises thread to cylinder shafts to allow swiveling.

Rod ends are internally threaded. They have an eyelet and ball that swivel to support angular misalignment and allow for pivoting.

Rod end nuts are internally threaded. They have an eyelet to make pivoting and hinge movements.

Stainless steel mounts are more corrosion resistant than steel and aluminum for use in wet or damp environments.

| For Bore Size, mm | Lg., mm | Ht., mm | Jaw Opening Wd., mm | Thread Size | Material | Includes | Each | |||

| 25, 32 | 52 | 20 | 10 | M10 × 1.25 mm | Zinc-Plated Steel | Nut, Pin | Round Body | Universal | 00000000 | 000000 |

| Shank Thread Size | ID, mm | Max. Ball Swivel | O'all Wd., mm | O'all Thick., mm | Shank Center Lg., mm | Shank Thread Lg., mm | Static Radial Load Cap., lbs. | Material | Shank Thread Direction | Each | |

| M10 × 1.25 mm | 10 | 17° | 27 | 14 | 43 | 21 | 11,250 | Zinc-Plated Chrome-Moly Steel | Right Hand | 00000000 | 000000 |

| M12 × 1.25 mm | 12 | 17° | 30 | 16 | 50 | 24 | 10,000 | Zinc-Plated Chrome-Moly Steel | Right Hand | 00000000 | 00000 |

| Shank Thread Size | ID, mm | Jaw Opening Wd., mm | O'all Wd., mm | Shank Center Lg., mm | Shank Thread Lg., mm | Jaw Center Lg., mm | Tensile Strength, psi | Material | Includes | Shank Thread Direction | Specifications Met | Each | |

| M12 × 1.25 mm | 12 | 12 | 24 | 48 | 24 | 24 | 60,000 | Zinc-Plated Carbon Steel | Snap-On Spring Clevis Pin | Right Hand | DIN 71752 | 0000000 | 000000 |

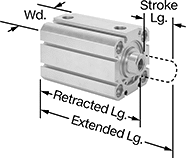

Flexible-Mount ISO Air Cylinders

For multiple mounting options, these air cylinders match an industry standard ISO footprint and have threaded holes on the face and sides. Their ISO footprint makes it easy to change out an old air cylinder. To mount them directly to equipment or add on attachments, use the threaded through holes. These cylinders are double acting, so they push and pull loads with equal force.

The piston is magnetic, so you can use these cylinders with sensors (not included) to activate relays and controllers. When the piston moves past a sensor, the sensor activates. You can use multiple sensors—one for each action you want to trigger.

For technical drawings and 3-D models, click on a part number.

Air Cylinders | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Air Inlet | Sensors | ||||||||||

| Stroke, mm | Retracted, mm | Extended, mm | Force @ 100 psi, lbs. | Body Material | Pipe Size | Thread Size | Thread Type | Gender | Each | Each | ||

20 mm Bore Size (36 mm Wd.) | ||||||||||||

| 80 | 123 | 203 | 49 | Aluminum | __ | M5 × 0.8 mm | Metric | Female | 0000000 | 000000 | 00000000 | 000000 |

25 mm Bore Size (40 mm Wd.) | ||||||||||||

| 80 | 125 | 205 | 75 | Aluminum | __ | M5 × 0.8 mm | Metric | Female | 0000000 | 00000 | 00000000 | 00000 |

32 mm Bore Size (48 mm Wd.) | ||||||||||||

| 80 | 131 | 211 | 124 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 00000 | 00000000 | 00000 |

50 mm Bore Size (68 mm Wd.) | ||||||||||||

| 80 | 133 | 213 | 303 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 000000 | 00000000 | 00000 |

63 mm Bore Size (78 mm Wd.) | ||||||||||||

| 80 | 137 | 217 | 482 | Aluminum | 1/8 | __ | BSPP | Female | 0000000 | 000000 | 00000000 | 00000 |

Base Mounting Holes | Top Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Wd., mm | Ht., mm | Dp., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Material | Each | |

| 20 | 23 | 22 | 36 | 4 | 2 | 7 | 22 | No | 2 | 6 | 22 | Yes | Zinc-Plated Steel | 00000000 | 00000 |

| 25 | 23 | 22 | 40 | 4 | 2 | 7 | 26 | No | 2 | 6 | 26 | Yes | Zinc-Plated Steel | 00000000 | 0000 |

| 32 | 35 | 26 | 45 | 4 | 2 | 7 | 32 | No | 2 | 7 | 32.5 | Yes | Zinc-Plated Steel | 00000000 | 00000 |

| 50 | 47 | 35 | 65 | 5 | 2 | 9 | 45 | No | 2 | 9 | 46.5 | Yes | Zinc-Plated Steel | 00000000 | 00000 |

| 63 | 47 | 35 | 75 | 5 | 2 | 9 | 50 | No | 2 | 9 | 56.5 | Yes | Zinc-Plated Steel | 00000000 | 00000 |

Inside Mounting Holes | Outside Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Wd., mm | Ht., mm | Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Material | Each | |

| 20 | 38 | 68 | 8 | 4 | 6 | 22 | Yes | 2 | 7 | 55 | No | Anodized Aluminum | 00000000 | 000000 |

| 25 | 38 | 73 | 8 | 4 | 6 | 26 | Yes | 2 | 7 | 60 | No | Anodized Aluminum | 00000000 | 00000 |

| 32 | 50 | 80 | 10 | 4 | 7 | 35.5 | Yes | 4 | 7 | 64 | No | Zinc-Plated Steel | 00000000 | 00000 |

| 50 | 65 | 110 | 12 | 4 | 9 | 46.5 | Yes | 4 | 9 | 90 | No | Zinc-Plated Steel | 00000000 | 00000 |

| 63 | 75 | 120 | 12 | 4 | 9 | 56.5 | Yes | 4 | 9 | 100 | No | Zinc-Plated Steel | 00000000 | 00000 |

Pin | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Dia., mm | Material | Wd., mm | Ht., mm | Dp., mm | Jaw Opening Wd., mm | Base Plate Thick., mm | No. of | Dia., mm | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Material | Includes | Each | |

| 32 | 10 | Steel | 45 | 45 | 32 | 26 | 10 | 4 | 7 | 32.5 | Yes | Zinc-Plated Steel | Four Washers, Two Snap Rings, One Pin | 00000000 | 000000 |

| 50 | 12 | Steel | 65 | 65 | 40 | 32 | 12 | 4 | 9 | 46.5 | Yes | Zinc-Plated Steel | Four Washers, Two Snap Rings, One Pin | 00000000 | 00000 |

| 63 | 16 | Steel | 75 | 75 | 50 | 40 | 12 | 4 | 9 | 56.5 | Yes | Zinc-Plated Steel | Four Washers, Two Snap Rings, One Pin | 00000000 | 00000 |

| For Bore Size, mm | Includes | Each | |

| 20 | Piston Seal, Rod Seal, Tube Gasket | 00000000 | 00000 |

| 25 | Piston Seal, Rod Seal, Rod Wiper, Two Tube Seals | 00000000 | 0000 |

| 32 | Piston Seal, Rod Seal, Rod Wiper, Two Tube Seals | 00000000 | 00000 |

| 50 | Piston Seal, Rod Seal, Rod Wiper, Two Tube Seals | 00000000 | 00000 |

| 63 | Piston Seal, Rod Seal, Rod Wiper, Two Tube Seals | 00000000 | 00000 |

Easy-Install Flexible-Mount Air Cylinders

With an integrated valve and multiple mounting options, these air cylinders install quickly, right where you need them, to push and pull light loads. In addition to saving you setup time, the built-in valve reduces the number of air connection points in your system to cut down on air loss. They have threaded holes on the face and sides for mounting either directly to equipment or using attachments. These air cylinders are double acting, meaning they extend and retract with nearly equal force.

The magnetic piston inside these cylinders can activate relays and controllers when used with a sensor (sold separately). When the piston moves past the sensor, the sensor activates. You can use multiple sensors—attach one for each action to trigger.

For technical drawings and 3-D models, click on a part number.

Lg. | Air Inlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke, mm | Retracted, mm | Extended, mm | Force @ 100 psi, lbs. | Air Cushion Type | Body Material | Tube OD, mm | Gender | Flow Coefficient (Cv) | Plug Type | Voltage | Maximum Flow Rate @ 100 psi | Each | |

20mm Bore Size (49mm Wd.) | |||||||||||||

| 80 | 130 | 210 | 45 | No Cushion | Aluminum | 6 | Female | 0.4 | 3-Pin M8 | 24V DC | 15scfm | 0000000 | 0000000 |

25mm Bore Size (53mm Wd.) | |||||||||||||

| 80 | 132 | 212 | 72 | No Cushion | Aluminum | 6 | Female | 0.4 | 3-Pin M8 | 24V DC | 15scfm | 0000000 | 000000 |

32mm Bore Size (60mm Wd.) | |||||||||||||

| 80 | 216 | 136 | 122 | No Cushion | Aluminum | 6 | Female | 0.4 | 3-Pin M8 | 24V DC | 15scfm | 0000000 | 000000 |

40mm Bore Size (69mm Wd.) | |||||||||||||

| 80 | 137 | 217 | 193 | No Cushion | Aluminum | 6 | Female | 0.4 | 3-Pin M8 | 24V DC | 15scfm | 0000000 | 000000 |

Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | For Pin Dia., mm | Wd., mm | Ht., mm | Dp., mm | Base Plate Thick., mm | No. of | Ctr.-to-Ctr., mm | Mounting Hardware Included | Material | Includes | Each | |

| 20 | 8 | 36 | 36 | 28 | 8 | 4 | 22 | Yes | Aluminum | __ | 0000000 | 000000 |

| 25 | 8 | 40 | 40 | 28 | 8 | 4 | 26 | Yes | Aluminum | __ | 0000000 | 00000 |

| 32 | __ | 48 | 48 | 32 | 10 | 4 | 32.5 | Yes | Aluminum | Four Bolts | 00000000 | 00000 |

| 40 | __ | 53 | 53 | 37 | 10 | 4 | 38 | Yes | Aluminum | Four Bolts | 00000000 | 00000 |

Pin | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Bore Size, mm | Dia., mm | Material | Wd., mm | Ht., mm | Dp., mm | Jaw Opening Wd., mm | Base Plate Thick., mm | No. of | Ctr.-to-Ctr., mm | Mounting Fasteners Included | Includes | Specifications Met | Specifications Met | Each | |

| 32 | 10 | Steel | 49 | 49 | 32 | 26 | 10 | 4 | 32.5 | Yes | Four Bolts, Pin, Retaining Clip | ISO 15552 | ISO 15552 | 00000000 | 000000 |

| 40 | 12 | Steel | 53 | 53 | 38 | 28 | 10 | 4 | 38 | Yes | Four Bolts, Pin, Retaining Clip | ISO 15552 | ISO 15552 | 00000000 | 00000 |

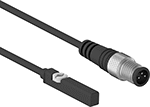

| For Bore Size | DC Voltage | Solid State Output | Each | |

| 1 1/2", 2", 2 1/2", 3 1/4", 20mm, 25mm, 32mm, 40mm | 10V DC-30V DC | NPN | 00000000 | 000000 |