How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Plastic and Rubber Tubing

More

About Metal Tubing

More

Metal Barbed Hose Fittings for Air and Water

Slide the barbed end into rubber hose and secure with the appropriate clamp or crimp-on hose ferrule.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. Plain brass fittings have good corrosion resistance. Nickel-plated brass fittings resist corrosion better than plain brass fittings.

Aluminum fittings are lighter in weight than other metal fittings. They have good corrosion resistance.

Stainless steel fittings have very good corrosion resistance. 303 stainless steel fittings won’t rust when exposed to water, making them good for areas that require frequent cleanings. Fittings with a threaded end are also known as hose nipples.

Hose connectors are also known as hose menders and splicers. Use them to connect lengths of hose or to repair damaged hose.

Metric, UN/UNF (SAE Straight), and BSPP male threads with gasket protect against leaks.

- Maximum Pressure: See table

- Maximum Vacuum: See table

- Temperature Range: See table

- Attachment Type: See table

- Specifications Met: See table

| For Hose ID | Pipe Size | Max. Pressure | Max. Vacuum | Temperature Range, °F | Attachment Type | Pkg. Qty. | Pkg. | |

Brass | ||||||||

|---|---|---|---|---|---|---|---|---|

| 18mm | 3/4 | 125 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 000000 |

Nickel-Plated Brass | ||||||||

| 18mm | 3/4 | 125 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

303 Stainless Steel | ||||||||

| 18mm | 3/4 | 250 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

| 18mm | 1 | 250 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

UN/UNF (SAE Straight)

Male Threads with Gasket

- Maximum Pressure: See table

- Maximum Vacuum: See table

- Temperature Range: See table

- Attachment Type: See table

- Specifications Met: Bronze Fittings: ASTM B584

| For Hose ID | Pipe Size | Gasket Material | Max. Pressure | Max. Vacuum | Temperature Range, °F | Attachment Type | Pkg. Qty. | Pkg. | |

Brass | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 18mm | 3/4 | Buna-N Rubber | 300 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 000000 |

Aluminum | |||||||||

| 18mm | 1 | Buna-N Rubber | 125 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

- Maximum Pressure: See table

- Maximum Vacuum: See table

- Temperature Range: See table

- Attachment Type: See table

- Specifications Met: See table

| For Hose ID | Pipe Size | Max. Pressure | Max. Vacuum | Temperature Range, °F | Attachment Type | Pkg. Qty. | Pkg. | |

Brass | ||||||||

|---|---|---|---|---|---|---|---|---|

| 18mm | 3/4 | 300 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 000000 |

303 Stainless Steel | ||||||||

| 18mm | 1 | 125 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

- Maximum Pressure: See table

- Maximum Vacuum: See table

- Temperature Range: See table

- Attachment Type: See table

- Specifications Met: See table

| For Hose ID | Max. Pressure | Max. Vacuum | Temperature Range, °F | Attachment Type | Pkg. Qty. | Pkg. | |

Brass | |||||||

|---|---|---|---|---|---|---|---|

| 18mm | 125 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 000000 |

- Maximum Pressure: See table

- Maximum Vacuum: See table

- Temperature Range: See table

- Attachment Type: See table

- Specifications Met: See table

For Hose ID | ||||||||

|---|---|---|---|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Max. Vacuum | Temperature Range, °F | Attachment Type | Pkg. Qty. | Pkg. | |

Brass | ||||||||

| 19mm | 18mm | 300 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 000000 |

Soft Plastic Tubing for Air and Water

This general purpose PVC tubing is the industry standard for air and water applications. Tubing is clear, so you can easily monitor flow. It is flexible to easily bend around objects.

Masterkleer tubing is more economical than Tygon tubing.

- Flexible

- Compatible with Barbed Tube Fittings

- Hardness: Soft (Durometer 70A)

- Temperature Range: -40° to 140° F

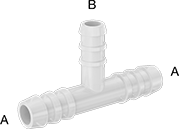

Plastic Barbed Tube Fittings for Air and Water

Fittings have barbs that grip onto tubing.

Acetal fittings won’t absorb water and lose strength, even in high-humidity environments.

- Temperature Range: -40° to 175° F

- Tubing: Use with firm or soft (Durometer 40A-80A) polyurethane rubber or PVC plastic

Inline tees are also known as branch tees.

General Purpose Copper Tubing

This tubing has good corrosion resistance and excellent heat transfer qualities. It is seamless, which provides a smooth interior for unrestricted flow. It can be flared without splitting. All tubing meets international standards for copper tubing.

- Temperature Range: -20° to 400° F

- Bendable: No

- Specifications Met: ASTM B68, ASTM B75

- Compatible Tube Fittings: Solder Connect

Aluminum Quick-Connect Pipe for Compressed Air

- For Use With: Air, Coolant, Nitrogen, Oil

- Maximum Pressure: 230 psi @ 72° F

- Specifications Met: ASTM B241

- Fittings: Use Quick-Disconnect Aluminum

Build a compressed air system in half the time it would take to build a copper or steel system. Also known as Unipipe, this pipe is part of a quick-connect system. The compatible fittings connect to this pipe when you finger tighten their collar and then use a wrench for the final quarter turn. A compression ring and O-ring inside the fitting seal it onto this pipe.

Choose blue or gray pipe for easy identification. Blue pipe is often used for compressed air systems. Gray pipe is often used for vacuum systems.

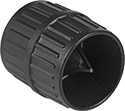

Use a deburring scraper (sold separately) to smooth rough edges left behind after trimming the pipe to size.

Place the tool over the end of your tube and twist to deburr.

| For Tube OD | Blade Material | Overall Lg. | Body Material | For Use On | Each | |

For Deburring Outer Tube Edges and Inner Tube Edges | ||||||

|---|---|---|---|---|---|---|

| 3/16"-1 1/2" | Steel | 2 1/4" | Zinc | Aluminum, Copper, Brass, Plastic | 0000000 | 000000 |