How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

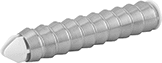

Metal Barbed Hose Fittings for Air and Water

Slide the barbed end into rubber hose and secure with the appropriate clamp or crimp-on hose ferrule.

Zinc-plated steel fittings are stronger and more durable than other metal fittings. They have fair corrosion resistance, so they should be used primarily in dry environments.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. Nickel-plated brass fittings resist corrosion better than plain brass fittings.

Fittings with a threaded end are also known as hose nipples.

- Maximum Pressure: See table

- Maximum Vacuum: See table

- Temperature Range: See table

- Attachment Type: See table

- Specifications Met: See table

| For Hose ID | Pipe Size | Max. Pressure | Max. Vacuum | Temperature Range, °F | Attachment Type | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 5/8" | 1/4 | 150 psi @ 72° F | 27 in. of Hg @ 72° F | -40° to 160° | Worm-Drive Clamp | 1 | 00000000 | 000000 |

| 5/8" | 3/8 | 150 psi @ 72° F | 27 in. of Hg @ 72° F | -40° to 160° | Worm-Drive Clamp | 1 | 00000000 | 00000 |

Nickel-Plated Brass | ||||||||

| 1" | 1 1/4 | 250 psi @ 72° F | 27 in. of Hg @ 72° F | -30° to 200° | Worm-Drive Clamp, Band-and-Buckle Clamp, Crimp-On Hose Ferrule | 1 | 00000000 | 00000 |

Metal Push-On Barbed Hose Fittings for Air and Water

Fittings have sharper barbs than standard barbed hose fittings to grip rubber push-on hose with no clamps or ferrules required. The more you pull on the fittings, the tighter the hose will grip.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. They have good corrosion resistance.

Fittings with a flared end meet JIC or SAE standards for dimensions. Fittings with a female 37° and 45° flared end have a dual-angle seat that accepts both 37° and 45° flared fittings.

The optional installation tool (sold separately) allows you to connect large quantities of barbed fittings to push-on hose. Use the built-in cutter to squarely cut the hose without fraying. Next, lubricate either the push-on hose, fitting or both. Then, clamp the hose into the tool’s vise and apply light pressure on the handle to drive into the fitting.

Note: To ensure proper connection, the barbed end has to be pushed in all the way, with the hose end concealed by the ring.

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -20° to 150° F

- Specifications Met: SAE J512, SAE J514

Mounting Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID Range | Lg. | Ht. | Dp. | Dia. | No. of | Mounting Fasteners Included | Each | |

| 1/4" to 3/4" | 13 1/2" | 7" | 2 3/8" | 5/8" | 4 | No | 00000000 | 0000000 |

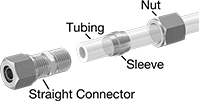

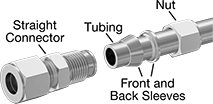

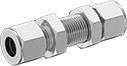

D.O.T. Brass Compression Tube Fittings for Air

- Temperature Range: -40° to 200° F

- Tubing: Use with hard (Durometer 65D) nylon plastic

- Specifications Met: D.O.T. FMVSS 571

Safe for use in your air brake line, these fittings meet Department of Transportation FMVSS 571 standards. They’ve been tested for thermal cycling, vibration, and burst pressure, so put them to work right away. They have a single sleeve (ferrule) that compresses the tubing as you tighten the included nut, creating a strong seal. All components are made of brass and are corrosion resistant. Also known as flareless fittings.

Vibration-Resistant Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 500° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See Table

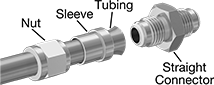

A PTFE seal on the tube end of these fittings allows for an extra-strong connection in high-vibration applications. The threads on the tube end are Class 3A and adhere to tighter tolerances than other 37° flared fittings. They are made to exact AS (formerly AN) specifications and provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings are 316 stainless steel for excellent corrosion resistance. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

| For Tube OD | Material | Max. Pressure | Specifications Met | For Hole Dia. | For Max. Wall Thick. | Each | |

| 1/2" | 316 Stainless Steel | 3,000 psi @ 72° F | AN832-8K, ASTM A380, SAE AS9100D, SAE AS9104/1 | 3/4" | 1/8" | 00000000 | 000000 |

| For Tube OD | Nut Material | Max. Pressure | Specifications Met | Each | |

| 1/2" | 316 Stainless Steel | 3,000 psi @ 72° F | AN818-8K, ASTM A380, SAE AS4841 | 00000000 | 000000 |

| For Tube OD | Sleeve Material | Max. Pressure | Specifications Met | Each | |

| 1/2" | 316 Stainless Steel | 3,000 psi @ 72° F | AN819-8K, ASTM A380, MS20819, SAE AS4841 | 00000000 | 000000 |

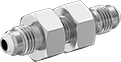

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Fittings with standard barbed hose end connect to hose with a hose clamp (sold separately).

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thick., mm | For Hose ID | Material | Max. Pressure | Temp. Range, °F | Each | |

| 10 | 0.5 to 2 | 1/2" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Fittings with push-on barbed hose end have sharper barbs than standard barbed hose fittings to grip reinforced rubber push-on hose with no clamps required. The more you pull on the fittings, the tighter the hose will grip.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | For Hose ID | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/2" | 0.035" | 1/2" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Fittings with tube stem insert into the tube end of another fitting in place of a length of tubing.

Fittings with push-on barbed hose end have sharper barbs than standard barbed hose fittings to grip reinforced rubber push-on hose with no clamps required. The more you pull on the fittings, the tighter the hose will grip.

| Tube Stem OD | For Hose ID | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/2" | 1/2" | 316 Stainless Steel | 300 psi @ 72° F | -40° to 200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | For Hole Dia. | For Max. Wall Thick. | Each | |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 5/8" | 9/16" | 00000000 | 000000 |

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sleeves | |||||||||

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 1 | 3/32" | 1 | 2,500 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 316 Stainless Steel | 19/64" | 1 | 5/32" | 1 | 2,000 psi @ 72° F | 00000000 | 0000 |

| 10mm | 0.5mm | 316 Stainless Steel | 5mm | 1 | 3mm | 1 | 2,500 psi @ 72° F | 00000000 | 0000 |

Sleeves with Dispenser | |||||||||

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 10 | 7/64" | 10 | 2,500 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 316 Stainless Steel | 9/32" | 10 | 5/32" | 10 | 2,000 psi @ 72° F | 00000000 | 00000 |

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each front sleeve, back sleeve, and nut is made of 316 stainless steel for excellent corrosion resistance. Five sets of sleeves and nuts come on each dispenser. Sleeves are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | Nut | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sets with Dispenser | |||||||||||

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 5 | 7/64" | 5 | 9/16" | 5 | 2,500 psi @ 72° F | 0000000 | 000000 |

| 1/2" | 0.035" | 316 Stainless Steel | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 2,000 psi @ 72° F | 0000000 | 00000 |

| 10mm | 1mm | 316 Stainless Steel | 5mm | 5 | 3mm | 5 | 15mm | 5 | 2,500 psi @ 72° F | 0000000 | 00000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Tube Support Style | Temp. Range, °F | Each | |

| 3/8" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

| 10mm | 8mm | 316 Stainless Steel | Barbed | -420° to 1200° | 00000000 | 0000 |

| 12mm | 10mm | 316 Stainless Steel | Barbed | -420° to 1200° | 00000000 | 0000 |

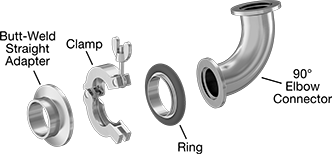

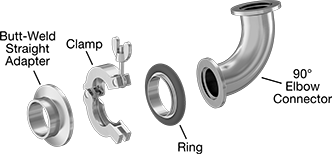

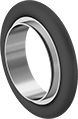

Quick-Clamp High-Vacuum Fittings for Stainless Steel Tubing

- For Use With:

Fittings with Gasket End: Air, Argon, Helium, Nitrogen

All Other Fittings: Air - Specifications Met: ISO 2861

Instead of a gasket, these fittings have a metal-reinforced O-ring that is designed for high-vacuum applications, such as vacuum coating and heat treating, leak testing, and analyzing gases. Also known as KF, QF, and NW fittings, they are the most common type of connection in high-vacuum systems. Connect with a clamp and another quick-clamp fitting for fast, easy access to your line. To use fittings in pressure applications, use a pressure-rated ring (sold separately). Made of 304 stainless steel, these fittings have very good corrosion resistance.

Note: To complete a connection, you’ll need two quick-clamp fittings, a ring, and a clamp (all sold separately).

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Fittings with claw-clamp end are often used to connect high-vacuum components with large-diameter connections, such as coating or heat-treating equipment, to components with smaller connections such as gauges, filters, or pumps. Also known as ISO-K fittings, they connect with four claw clamps and a ring (sold separately).

Quick-Clamp Tube Connection | Claw-Clamp Tube Connection | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Max. Vacuum | Max. Pressure | Each | |

| 1" | 1.57" | 25 | ISO-KF | 2 1/2" | 3.74" | 63 | ISO-K | 10 -8 torr @ 72° F | 5 psi @ 72° F | 00000000 | 0000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 2 1/2" | 3.74" | 63 | ISO-K | 10 -8 torr @ 72° F | 5 psi @ 72° F | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 3" | 4.33" | 80 | ISO-K | 10 -8 torr @ 72° F | 5 psi @ 72° F | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 4" | 5.12" | 100 | ISO-K | 10 -8 torr @ 72° F | 5 psi @ 72° F | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 2 1/2" | 3.74" | 63 | ISO-K | 10 -8 torr @ 72° F | 5 psi @ 72° F | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 3" | 4.33" | 80 | ISO-K | 10 -8 torr @ 72° F | 5 psi @ 72° F | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 4" | 5.12" | 100 | ISO-K | 10 -8 torr @ 72° F | 5 psi @ 72° F | 00000000 | 000000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Clamps tighten by hand.

Lever clamps are also known as toggle clamps.

Clamps with lanyard let you secure the clamp to equipment.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Lanyard Lg. | Each | |

Wing Nut | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

Lever | ||||||||

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

Lever with Lanyard | ||||||||

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

- Temperature Range:

Fittings with Viton® Fluoroelastomer Rubber O-Ring: 0° to 300° F

Fittings with Silicone Rubber O-Ring: -50° to 390°F - Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Use these rings with quick-clamp high-vacuum fittings. They consist of a stainless steel inner ring covered by an O-ring.

Silicone rings withstand higher temperatures than fluoroelastomer ones.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Inner Ring Material | Max. Vacuum | Max. Pressure | Each | |

Viton® Fluoroelastomer Rubber O-Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

Rings | ||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 0000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 0000000 | 00000 |

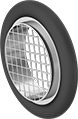

Rings with Stainless Steel Screen | ||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

Rings with Aluminum Outer Ring | ||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 100 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 75 psi @ 72° F | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 50 psi @ 72° F | 0000000 | 00000 |

Silicone Rubber O-Ring | ||||||||

Rings | ||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

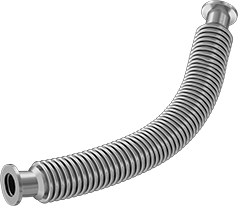

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Hose absorbs moderate vibration

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Bend Radius | Flexibility | Each | |

4 3/16" Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

12" Lg. | |||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

24" Lg. | |||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

39" Lg. | |||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

- Temperature Range: 0° to 190° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Valves are also known as vacuum isolation valves. They connect to a vacuum system so you can install gauges, release gases, and remove air. They operate manually and have a compact body that fits easily into tight spaces.

| Actuation | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Max. Vacuum | Body Material | Overall Ht. | Overall Lg. | Each | |

| Manual | 1" | 1 9/16" | 25 | ISO-KF | 10 -8 torr @ 72° F | 304 Stainless Steel | 5 5/8" | 3" | 00000000 | 0000000 |

| Manual | 1 1/2" | 2 1/8" | 40 | ISO-KF | 10 -8 torr @ 72° F | 304 Stainless Steel | 6 3/8" | 3 7/8" | 00000000 | 000000 |

| Manual | 2" | 2 15/16" | 50 | ISO-KF | 10 -8 torr @ 72° F | 304 Stainless Steel | 8" | 4 1/2" | 00000000 | 000000 |

Flanged Ultra-High-Vacuum Fittings for Stainless Steel Tubing

- For Use With: Air

- Temperature Range:

Flanges: -300° to 800° F

Gaskets: Not Rated - Tubing: Use with 304/304L and 316/316L stainless steel

- Specifications Met:

Flanges: ASTM A240, ASTM E45, ASTM E12

Gaskets: ASTM B152-179, ASTM F68

Create access points in ultra-high-vacuum lines or chambers by bolting two same-size flanges together with a copper gasket (sold separately) between them. The flanges’ sharp edges dig into the copper gasket and form an extremely tight seal, which means they handle higher vacuum pressures than other high-vacuum fittings with rubber gaskets. Also known as CF, Conflat, and UHV fittings, use them in vacuum coating, heat treating, and drying applications, as well as for leak testing and analyzing gases. They’re stainless steel so they resist rusting.

Butt-weld flanges provide a flush connection for smooth flow through your line.

Bolt kits are required to make a complete connection.

Butt-Weld Tube Connection | Flanged Tube Connection | Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Wall Thick. | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Lg. | Max. Vacuum | Material | Appearance | Each | |

Fixed | ||||||||||||||||

| 1 1/2" | 0.065" | 1 1/2" | 2 3/4" | 40 | CF | 2 5/16" | 17/64" | 6 | No | 1 | 2 15/32" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 000000 |

| For Tube OD | For Flange OD | Gasket Material | Specifications Met | Each | |

| 1 1/2" | 2 3/4" | Copper | ASTM F68 | 0000000 | 00000 |

| For Flange OD | For High-Vacuum Flange Size | Bolt Dia. | Thread Size | No. of Bolts Included | No. of Nuts Included | No. of Washers Included | Bolt Material | Each | |

| 2 3/4" | 40 | 1/4" | 1/4"-28 | 6 | 6 | 12 | 18-8 Stainless Steel | 0000000 | 000000 |