How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

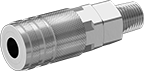

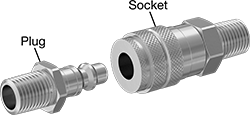

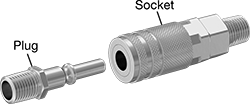

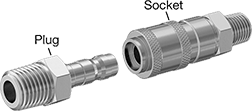

Industrial Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately or in a set) that connect and disconnect quickly. Use them if you need frequent access to a line. They are also known as industrial interchange couplings. All Industrial plugs are compatible with any of the Industrial sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Steel is stronger and more durable than other metals. Zinc-plated steel has fair corrosion resistance and should be used primarily in dry environments. Brass is softer than other metals, so it’s easier to thread together. It has good corrosion resistance. Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -40° to 225° F

- Specifications Met: See table

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Sleeve-lock sockets connect by sliding back the sleeve on the socket, inserting the plug, and releasing the sleeve. To disconnect, slide the sleeve back and pull out the plug.

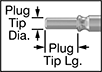

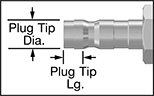

For Plug Tip | ||||||

|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Specifications Met | Each | |

Brass | ||||||

| 1/2 | 3/8" | 9/16" | 1/4 | Fed. Spec. A-A-59439, ISO 6150/B | 00000000 | 000000 |

- Maximum Pressure: 300 psi @ 72° F

- Maximum Vacuum: 26 in. of Hg @ 72° F

- Temperature Range: -40° to 225° F

- Specifications Met: ISO 6150/B

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Twist sockets connect by inserting the plug into the socket and sliding the socket forward until it locks in place. To disconnect, slide the sleeve back while twisting it left and right; the twisting action vents the downstream air to release pressure, making it safe to remove the plug.

For Plug Tip | |||||

|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Each | |

Zinc-Plated Steel | |||||

| 3/8 | 5/16" | 7/16" | 3/8 | 0000000 | 000000 |

Lincoln Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them if you need frequent access to a line. All Lincoln plugs are compatible with any of the Lincoln sockets, regardless of the pipe size.

Plugs and sockets with a shut-off valve have a valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Sleeve-lock sockets connect by sliding back the sleeve on the socket, inserting the plug, and releasing the sleeve. To disconnect, slide the sleeve back and pull out the plug.

Zinc-plated steel is stronger and more durable than other metals. It has fair corrosion resistance, so it should be used primarily in dry environments.

Brass is softer than other metals, so it’s easier to thread together. It has good corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -40° to 240° F

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Type | Flow Control | Each | |

Brass | |||||||

| 1/4 | 3/4" | 9/32" | 1/4 | NPT | With Shut-Off | 00000000 | 000000 |

Compact Quick-Disconnect Hose Couplings for Air

A slim body allows these couplings to fit into tight spaces. A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them if you need frequent access to a line. All Compact plugs are compatible with any of the Compact sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line. They are push-to-connect style. To connect, push the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects.

Plugs and sockets with a barbed end insert into plastic or rubber hose and secure with a crimp-on hose ferrule.

Brass is softer than zinc-plated steel, so it’s easier to thread together. It offers good corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

- Maximum Pressure: 500 psi @ 72° F

- Temperature Range: -40° to 250° F

- Attachment Type: Use Crimp-On Hose Ferrules

For Plug Tip | |||||

|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | For Hose ID | Each | |

Brass | |||||

| 1/4 | 7/32" | 5/16" | 1/4" | 00000000 | 000000 |

Metal Barbed Hose Fittings for Air and Water

Slide the barbed end into rubber hose and secure with the appropriate clamp or crimp-on hose ferrule.

Bronze fittings have better corrosion resistance and are stronger than brass and aluminum fittings. Fittings with a threaded end are also known as hose nipples.

- Maximum Pressure: See table

- Maximum Vacuum: See table

- Temperature Range: See table

- Attachment Type: See table

- Specifications Met: See table

| For Hose ID | Pipe Size | Max. Pressure | Max. Vacuum | Temperature Range, °F | Attachment Type | Specifications Met | Pkg. Qty. | Pkg. | |

Bronze | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 5/8" | 1/2 | 100 psi @ 72° F | Not Rated | 32° to 212° | Worm-Drive Clamp | ASTM B584, UL 1121 | 1 | 0000000 | 00000 |

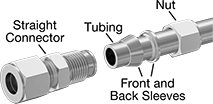

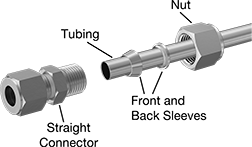

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | For Hole Dia. | For Max. Wall Thick. | Each | |

NPT Threads | |||||||||

| 1/2" | 0.035" | 1/2 | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 3/4" | 19/32" | 00000000 | 000000 |

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each front sleeve, back sleeve, and nut is made of 316 stainless steel for excellent corrosion resistance. Five sets of sleeves and nuts come on each dispenser. Sleeves are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | Nut | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sets with Dispenser | |||||||||||

| 1/2" | 0.035" | 316 Stainless Steel | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 2,000 psi @ 72° F | 0000000 | 000000 |

PTFE sleeves are plastic instead of stainless steel, so they won’t damage tubing.

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/2" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Tube Support Style | Temp. Range, °F | Each | |

| 1/2" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 000000 |

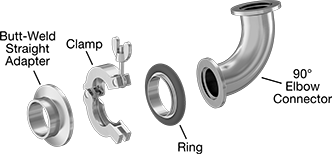

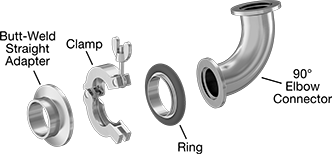

Quick-Clamp High-Vacuum Fittings for Stainless Steel Tubing

- For Use With:

Fittings with Gasket End: Air, Argon, Helium, Nitrogen

All Other Fittings: Air - Specifications Met: ISO 2861

Instead of a gasket, these fittings have a metal-reinforced O-ring that is designed for high-vacuum applications, such as vacuum coating and heat treating, leak testing, and analyzing gases. Also known as KF, QF, and NW fittings, they are the most common type of connection in high-vacuum systems. Connect with a clamp and another quick-clamp fitting for fast, easy access to your line. To use fittings in pressure applications, use a pressure-rated ring (sold separately). Made of 304 stainless steel, these fittings have very good corrosion resistance.

Note: To complete a connection, you’ll need two quick-clamp fittings, a ring, and a clamp (all sold separately).

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Fittings with flanged end connect to pumps, valves or gauges that have flanged connections. Also known as conflat, CF, or UHV fittings, they have a higher vacuum rating than quick-clamp fittings, so these adapters allow you to connect between different levels of vacuum within a system. A copper gasket (sold separately) creates a tight seal between the two flanges.

Quick-Clamp Tube Connection | Flanged Tube Connection | Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | For Bolt Dia. | Bolts Included | Max. Vacuum | Max. Pressure | Each | |

| 1" | 1.57" | 25 | ISO-KF | 3/4" | 1 21/64" | 16 | CF | 1 1/16" | 11/64" | 6 | 5/32" | No | 10 -8 torr @ 72° F | 5 psi @ 72° F | 00000000 | 000000 |

| Copper Gasket for 1 21/64" Flange OD (Flanged End) | 0000000 | Each | 00000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Clamps tighten by hand.

Lever clamps are also known as toggle clamps.

Clamps with lanyard let you secure the clamp to equipment.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Lanyard Lg. | Each | |

Wing Nut | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 000000 |

Lever | ||||||||

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

Lever with Lanyard | ||||||||

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

- Temperature Range:

Fittings with Viton® Fluoroelastomer Rubber O-Ring: 0° to 300° F

Fittings with Silicone Rubber O-Ring: -50° to 390°F - Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Use these rings with quick-clamp high-vacuum fittings. They consist of a stainless steel inner ring covered by an O-ring.

Silicone rings withstand higher temperatures than fluoroelastomer ones.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Inner Ring Material | Max. Vacuum | Max. Pressure | Each | |

Viton® Fluoroelastomer Rubber O-Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

Rings | ||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 0000000 | 000000 |

Rings with Stainless Steel Screen | ||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

Rings with Aluminum Outer Ring | ||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 100 psi @ 72° F | 0000000 | 00000 |

Silicone Rubber O-Ring | ||||||||

Rings | ||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

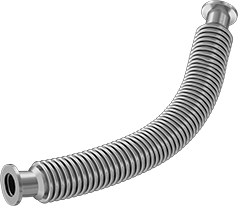

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Hose absorbs moderate vibration

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Bend Radius | Flexibility | Each | |

4 3/16" Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

12" Lg. | |||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

24" Lg. | |||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

39" Lg. | |||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are brass for good corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | For Hole Dia. | For Max. Wall Thick. | Each | |

NPT Threads | ||||||||

| 1/2" | 0.049" | 1/2 | Brass | 1,200 psi @ 72° F | 3/4" | 1/2" | 00000000 | 000000 |

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1/2" | Brass | 800 psi @ 72° F | 00000000 | 00000 |

Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

| 1/2" | Brass | 19/64" | 1 | 5/32" | 1 | 800 psi @ 72° F | 00000000 | 00000 |

Save time installing sleeves—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each set includes a front and back sleeve. The sleeves are also known as ferrules.

Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

| 1/2" | Brass | 19/64" | 10 | 9/64" | 10 | 1,200 psi @ 72° F | 00000000 | 000000 |

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each set includes a front sleeve, a back sleeve, and a nut. The sleeves are also known as ferrules.

Front Sleeve | Back Sleeve | Nut | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

| 1/2" | Brass | 3/16" | 5 | 7/64" | 5 | 11/16" | 5 | 1,200 psi @ 72° F | 0000000 | 000000 |

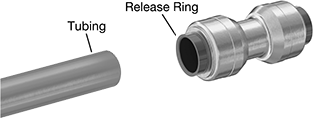

Brass Push-to-Connect Fittings for Copper Tubing

- Tubing: Use with K, M, L copper, polyethylene plastic, CPVC

Connect these fittings to copper tubing with a push—no heat, solder, or flux required. They have an internal gripping ring and O-ring that hold the fitting secure. They also come with a tube support or retainer if you want to use them with polyethylene plastic (PEX) tubing. They are also known as instant fittings. Fittings are brass for good corrosion resistance. They are compatible with SharkBite® fittings. To adhere to safety standards for drinking water systems, use fittings that meet NSF/ANSI 61.

- For Use With: Air, Drinking Water

- Temperature Range: 32° to 200° F

- Specifications Met: NSF/ANSI 61

Standard Caps | |||||||

|---|---|---|---|---|---|---|---|

| Copper Tube Size | For Tube OD | Material | Release Ring Material | Release Ring Color | Max. Pressure | Each | |

| 1 1/2 | 1 5/8" | Brass | Plastic | Black | 200 psi @ 72° F | 0000000 | 000000 |