How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Easy-Fit Barbed Hose Fittings for Air and Water

Low-profile barbs and a longer first barb allow for a smoother, easier installation than other barbed fittings. Slide the barbed end into rubber hose and secure with a clamp.

Steel fittings are stronger and more durable than other metal fittings. They should be used in noncorrosive environments. Zinc-plated steel fittings have slightly better corrosion resistance than unplated steel fittings. Fittings with a threaded end are also known as hose nipples.

- Maximum Pressure: 125 psi @ 72° F, except For 5" to 8" Hose IDs: 100 psi @ 72° F

- Maximum Vacuum: For 1/2" to 4" Hose IDs: 26 in. of Hg @ 72° F

- Temperature Range: -20° to 200° F

- Attachment Type: Use Worm-Drive Clamps, Bolt Clamps or Band-and-Buckle Clamps

- Specifications Met: See table

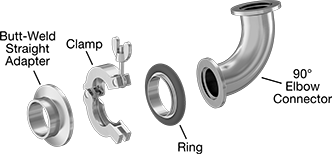

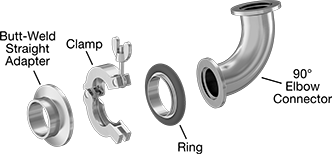

Quick-Clamp High-Vacuum Fittings for Stainless Steel Tubing

- For Use With:

Fittings with Gasket End: Air, Argon, Helium, Nitrogen

All Other Fittings: Air - Specifications Met: ISO 2861

Instead of a gasket, these fittings have a metal-reinforced O-ring that is designed for high-vacuum applications, such as vacuum coating and heat treating, leak testing, and analyzing gases. Also known as KF, QF, and NW fittings, they are the most common type of connection in high-vacuum systems. Connect with a clamp and another quick-clamp fitting for fast, easy access to your line. To use fittings in pressure applications, use a pressure-rated ring (sold separately). Made of 304 stainless steel, these fittings have very good corrosion resistance.

Note: To complete a connection, you’ll need two quick-clamp fittings, a ring, and a clamp (all sold separately).

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L or 316/316L stainless steel

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Lg. | Material | Max. Vacuum | Each | |

| 2" | 2.95" | 50 | ISO-KF | 5 1/2" | 304 Stainless Steel | 10 -8 torr @ 72° F | 00000000 | 0000000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Clamps tighten by hand.

Lever clamps are also known as toggle clamps.

Clamps with lanyard let you secure the clamp to equipment.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Lanyard Lg. | Each | |

Wing Nut | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 000000 |

Lever | ||||||||

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

Lever with Lanyard | ||||||||

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

- Temperature Range:

Fittings with Viton® Fluoroelastomer Rubber O-Ring: 0° to 300° F

Fittings with Silicone Rubber O-Ring: -50° to 390°F - Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Use these rings with quick-clamp high-vacuum fittings. They consist of a stainless steel inner ring covered by an O-ring.

Silicone rings withstand higher temperatures than fluoroelastomer ones.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Inner Ring Material | Max. Vacuum | Max. Pressure | Each | |

Viton® Fluoroelastomer Rubber O-Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

Rings | ||||||||

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 0000000 | 000000 |

Rings with Stainless Steel Screen | ||||||||

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

Rings with Aluminum Outer Ring | ||||||||

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 50 psi @ 72° F | 0000000 | 00000 |

Silicone Rubber O-Ring | ||||||||

Rings | ||||||||

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

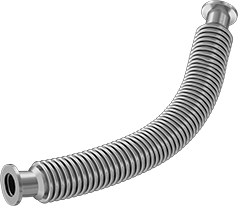

Hose absorbs moderate vibration

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Bend Radius | Flexibility | Each | |

4 3/16" Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | __ | Flexible | 0000000 | 0000000 |

12" Lg. | |||||||||

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

24" Lg. | |||||||||

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

39" Lg. | |||||||||

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

- Temperature Range: 0° to 190° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Valves are also known as vacuum isolation valves. They connect to a vacuum system so you can install gauges, release gases, and remove air. They operate manually and have a compact body that fits easily into tight spaces.

| Actuation | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Max. Vacuum | Body Material | Overall Ht. | Overall Lg. | Each | |

| Manual | 2" | 2 15/16" | 50 | ISO-KF | 10 -8 torr @ 72° F | 304 Stainless Steel | 8" | 4 1/2" | 00000000 | 0000000 |

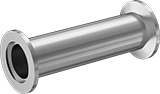

Butt-Weld Fittings for Stainless Steel Tubing

- For Use With: See table

- Temperature Range: See table

- Tubing:

304 Stainless Steel: Use with 304/304L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except DIN EN 10357 fittings with only ASTM A269 or ASTM A270

316 Stainless Steel: Use with 316/316L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except ASME BPE and DIN EN 10357 fittings with only ASTM A269 or ASTM A270 - Specifications Met: See table

Weld these fittings to tubing for a permanent, flush connection that permits smooth flow through a line.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

ASME BPE fittings are polished to a 20 Ra finish for an extra-smooth interior that prevents product buildup and bacteria growth. Use them in pharmaceutical and bioprocessing applications.

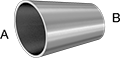

| For Tube OD (A) | For Tube OD (B) | Max. Pressure | Max. Vacuum | Temp. Range, °F | Wall Thick. | For Use With | Each | ||

304/304L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Dull | |||||||||

| 1 | 6" | 4" | 120 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.083" | Air, Food, Water | 00000000 | 0000000 |

316/316L Stainless Steel | |||||||||

Dull | |||||||||

| 1 | 6" | 4" | 120 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.109" | Air, Food, Water | 00000000 | 000000 |

Offset straight reducers are also known as eccentric reducers. They have offset centers so your line can drain.

304/304L Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD (A) | For Tube OD (B) | Max. Pressure | Max. Vacuum | Temp. Range, °F | Wall Thick. | For Use With | Each | |

Dull | ||||||||

| 6" | 4" | 120 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 0.083" | Air, Food, Water | 00000000 | 0000000 |

316/316L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

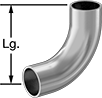

| For Tube OD | Max. Pressure | Temp. Range, °F | Length | Wall Thick. | For Use With | Specifications Met | Certification | Each | |

Polished | |||||||||

| 2 1/2" | 200 psi @ 72° F | -65° to 200° | 5 1/2" | 0.065" | Air, Deionized Water, Pharmaceuticals, Water | ASME BPE | Material Certificate with Traceable Lot Number and Test Report | 000000000 | 000000 |