Filter by

Airflow Pattern

Material

For Use With

Air Inlet Location

Volume (Sound)

Air Inlet Connection

Air Inlet Thread Type

Maximum Temperature

Air Inlet Pipe Size

Air Inlet Connection Port

Air Consumption @ Pressure

Air Inlet Gender

Airflow Slot Depth

Air Inlet Thread Engagement

Air Inlet Threads per Inch

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Specifications Met

Maximum Inlet Pressure

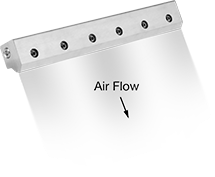

High-Efficiency Air Knives

|

Producing the same airflow as standard air knives, these are quieter and use 18% less compressed air. Air knives create a sheet of high-velocity air for drying and cooling parts, wiping conveyor belts, controlling coating depth, and blowing liquids, chips, and dust from equipment. They conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure and OSHA 29 CFR 1910.95 requirements for noise.

Air knives can be mounted with a positioning arm or mounting bracket (sold separately).

3" Overall Width and 6" Overall Width—Knives up to 6” wide can be supported with rigid pipe connected to your air supply.

Volume (Sound)—Volume (sound) is measured 3 ft. from the air knife.

Air Knife Shim Sets—Air knife shim sets (sold separately) install in the airflow slot to adjust the flow and force of air.

Air Knives | Air Knife Shim Sets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Airflow | Overall | Air Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slot Wd. | Slot Dp. | Air Consumption @ Pressure | Volume (Sound), dBA | Wd. | Ht. | Dp. | Max. Temp., ° F | Max. Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Specs. Met | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.002" | 11 ft³/min @ 100 psi | 72 | 3" | 1 7/16" | 1 3/4" | 180 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K11 | 0000000 | 6069K51 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 0.002" | 21 ft³/min @ 100 psi | 72 | 6" | 1 7/16" | 1 3/4" | 180 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K12 | 000000 | 6069K52 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 0.002" | 32 ft³/min @ 100 psi | 72 | 9" | 1 7/16" | 1 3/4" | 180 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K26 | 000000 | 6069K58 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 0.002" | 42 ft³/min @ 100 psi | 72 | 12" | 1 7/16" | 1 3/4" | 180 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K13 | 000000 | 6069K53 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 0.002" | 63 ft³/min @ 100 psi | 72 | 18" | 1 7/16" | 1 3/4" | 180 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K14 | 000000 | 6069K54 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 0.002" | 84 ft³/min @ 100 psi | 72 | 24" | 1 7/16" | 1 3/4" | 180 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K15 | 000000 | 6069K55 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 0.002" | 105 ft³/min @ 100 psi | 72 | 30" | 1 7/16" | 1 3/4" | 180 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K16 | 000000 | 6069K56 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 0.002" | 126 ft³/min @ 100 psi | 72 | 36" | 1 7/16" | 1 3/4" | 180 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K17 | 000000 | 6069K57 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42" | 0.002" | 147 ft³/min @ 100 psi | 72 | 42" | 1 7/16" | 1 3/4" | 180 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K31 | 00000000 | 6069K35 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 0.002" | 168 ft³/min @ 100 psi | 72 | 48" | 1 7/16" | 1 3/4" | 180 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K32 | 00000000 | 6069K36 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.002" | 11 ft³/min @ 100 psi | 72 | 3" | 1 1/16" | 1 7/16" | 800 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K18 | 000000 | 6069K61 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 0.002" | 21 ft³/min @ 100 psi | 72 | 6" | 1 1/16" | 1 7/16" | 800 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K19 | 000000 | 6069K62 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 0.002" | 32 ft³/min @ 100 psi | 72 | 9" | 1 1/16" | 1 7/16" | 800 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K29 | 000000 | 6069K68 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 0.002" | 42 ft³/min @ 100 psi | 72 | 12" | 1 1/16" | 1 7/16" | 800 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K21 | 000000 | 6069K63 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 0.002" | 63 ft³/min @ 100 psi | 72 | 18" | 1 1/16" | 1 7/16" | 800 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K22 | 00000000 | 6069K64 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 0.002" | 84 ft³/min @ 100 psi | 72 | 24" | 1 1/16" | 1 7/16" | 800 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K23 | 00000000 | 6069K65 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 0.002" | 105 ft³/min @ 100 psi | 72 | 30" | 1 1/16" | 1 7/16" | 800 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K24 | 00000000 | 6069K66 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 0.002" | 126 ft³/min @ 100 psi | 72 | 36" | 1 1/16" | 1 7/16" | 800 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K25 | 00000000 | 6069K67 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42" | 0.002" | 147 ft³/min @ 100 psi | 72 | 42" | 1 1/16" | 1 7/16" | 800 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K33 | 00000000 | 6069K37 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 0.002" | 168 ft³/min @ 100 psi | 72 | 48" | 1 1/16" | 1 7/16" | 800 | 250 | 1/4 | NPT | Female | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6069K34 | 00000000 | 6069K38 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

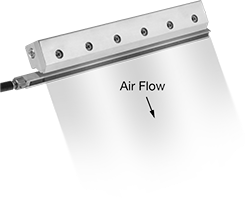

High-Efficiency Static-Eliminating Air Knives

|

These produce the same airflow as standard static-eliminating air knives but are quieter and use 18% less compressed air. They have an ionizing bar that temporarily neutralizes static to protect against ESD (electrostatic discharge). Air knives create a sheet of high-velocity air for drying and cooling parts, wiping conveyor belts, controlling coating depth, and blowing liquids, chips, and dust from equipment. They conform to OSHA 29 CFR 1910.242 requirements for maximum air outlet pressure and OSHA 29 CFR 1910.95 requirements for noise.

Air knives can be mounted with a positioning arm or mounting bracket (sold separately).

4 5/8" Overall Width—Knives up to 4 5/8" can be supported with rigid pipe connected to your air supply.

Volume (Sound)—Volume (sound) is measured 3 ft. from the air knife.

Air Knife Shim Sets—Air knife shim sets (sold separately) install in the airflow slot to adjust the flow and force of air.

Air Knives | Air Knife Shim Sets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Airflow | Overall | Air Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slot Wd. | Slot Dp. | Air Consumption @ Pressure | Volume (Sound), dBA | Wd. | Ht. | Dp. | Max. Temp., ° F | Max. Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Static Neutralizing Distance | Specs. Met | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.002" | 10.5 ft³/min @ 100 psi | 72 | 4 5/8" | 1 7/8" | 2 1/4" | 165 | 250 | 1/4 | NPT | Female | 6" to 20 ft. | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6101K41 | 0000000 | 6069K51 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 0.002" | 21 ft³/min @ 100 psi | 72 | 7 5/8" | 1 7/8" | 2 1/4" | 165 | 250 | 1/4 | NPT | Female | 6" to 20 ft. | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6101K42 | 000000 | 6069K52 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 0.002" | 42 ft³/min @ 100 psi | 72 | 13 5/8" | 1 7/8" | 2 1/4" | 165 | 250 | 1/4 | NPT | Female | 6" to 20 ft. | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6101K43 | 000000 | 6069K53 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 0.002" | 63 ft³/min @ 100 psi | 72 | 19 5/8" | 1 7/8" | 2 1/4" | 165 | 250 | 1/4 | NPT | Female | 6" to 20 ft. | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6101K44 | 00000000 | 6069K54 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 0.002" | 84 ft³/min @ 100 psi | 72 | 25 5/8" | 1 7/8" | 2 1/4" | 165 | 250 | 1/4 | NPT | Female | 6" to 20 ft. | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6101K45 | 00000000 | 6069K55 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 0.002" | 126 ft³/min @ 100 psi | 72 | 37 5/8" | 1 7/8" | 2 1/4" | 165 | 250 | 1/4 | NPT | Female | 6" to 20 ft. | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 6101K46 | 00000000 | 6069K57 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||