Filter by

Power Source

For Use With

Housing Material

Maximum Flow Rate

Maximum Pressure

Material

Voltage

Wetted Parts Material

Air Pressure

Maximum Temperature

Priming Type

DFARS Specialty Metals

High-Pressure Air-Powered Drum Pumps for Oil

Temp., ° F | Intake | Discharge | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | |||

| 6 | 15 | 8,750 | 10 | 150 | 0 to 150 | 14 | 2 NPT | Drum Connector | 1/4 Female NPTF | 1 3/4" | 22" | Pump Body | Threaded | 1/2 Female NPT | 4262K52 | 0000000 | ||

| 10 | 55 | 1,500 | Not Rated | 140 | 30 to 150 | 9 | 2 NPT | Drum Connector | 1/4 Female NPT | 2" | 37" | Pump Body | Threaded | 1/2 Female NPT | 4346K35 | 000000 | ||

Air-Powered Container-Mount Oil Dispensers

Air Inlet | For Max. Viscosity | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Container Size, gal. | Flow Rate, gpm | Max. Oil Outlet Pressure, psi | Oil Outlet Hose Lg., ft. | Material | Pressure, psi | Hose Lg., ft. | Thread Type | Pipe Size | Gender | ISO Grade | SAE Grade | SSU Grade, SSU | AGMA Grade | Includes | Each | ||

| 55 | 1.8 | 540 | 6 | Aluminum | 40 to 180 | 6 | NPT | 3/8 | Female | 1500 | 250 | 9,000 | 8 | Bung Adapter with a 2 NPT Male Connection, Pump, Air Inlet Hose, Air Pressure Regulator with Gauge, Oil Outlet Hose | 2332K5 | 000000000 | |

Air-Powered Oil-Dispensing Pumps

|  |  |  |

1 Pump | 2 Pumps | 4 Pumps | 6 Pumps |

|  |  | |

1 Pump with Spray Nozzle | 2 Pumps with Spray Nozzle | 4 Pumps with Spray Nozzle |

Oil Inlet | Overall | Air Inlet | Mounting | For Max. Viscosity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pumps | oz. per Cycle, fl. oz. | Dispensing Interval, sec. | Max. Oil Outlet Pressure, psi | Pump Material | Thread Type | Pipe Size | Gender | Ht. | Wd. | Dp. | Air Inlet Pressure, psi | Thread Type | Pipe Size | Gender | Temp. Range, ° F | Hole Dia. | Fasteners Included | ISO Grade | SAE Grade | SSU Grade, SSU | AGMA Grade | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Dispensing Pumps | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Female Oil Outlets | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 0 to 0.007 | 0.5 to 1 | 1,080 | Aluminum | NPT | 1/8 | Female | 4" | 2" | 1 1/8" | 40 to 120 | NPT | 1/8 | Female | -15 to 180 | 9/32" | No | 220 | 90 | 1,000 | 5 | 2279K51 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 0 to 0.007 | 0.5 to 1 | 1,080 | Aluminum | NPT | 1/8 | Female | 4" | 3 1/4" | 1 1/8" | 40 to 120 | NPT | 1/8 | Female | -15 to 180 | 9/32" | No | 220 | 90 | 1,000 | 5 | 2279K52 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 0 to 0.007 | 0.5 to 1 | 1,080 | Aluminum | NPT | 1/8 | Female | 4" | 5 3/4" | 1 1/8" | 40 to 120 | NPT | 1/8 | Female | -15 to 180 | 9/32" | No | 220 | 90 | 1,000 | 5 | 2279K53 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 0 to 0.007 | 0.5 to 1 | 1,080 | Aluminum | NPT | 1/8 | Female | 4" | 8 1/4" | 1 1/8" | 40 to 120 | NPT | 1/8 | Female | -15 to 180 | 9/32" | No | 220 | 90 | 1,000 | 5 | 2279K54 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Dispensing Pumps with Spray Nozzle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Female Oil Outlets | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 0 to 0.007 | 0.5 to 1 | 1,080 | Aluminum | NPT | 1/8 | Female | 4" | 2" | 1 1/8" | 40 to 120 | NPT | 1/8 | Female | -15 to 180 | 9/32" | No | 220 | 90 | 1,000 | 5 | 2279K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 0 to 0.007 | 0.5 to 1 | 1,080 | Aluminum | NPT | 1/8 | Female | 4" | 3 1/4" | 1 1/8" | 40 to 120 | NPT | 1/8 | Female | -15 to 180 | 9/32" | No | 220 | 90 | 1,000 | 5 | 2279K42 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 0 to 0.007 | 0.5 to 1 | 1,080 | Aluminum | NPT | 1/8 | Female | 4" | 5 3/4" | 1 1/8" | 40 to 120 | NPT | 1/8 | Female | -15 to 180 | 9/32" | No | 220 | 90 | 1,000 | 5 | 2279K43 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Compact Air-Powered Double Diaphragm Pumps

Barbed Bottom Intake and Barbed Bottom Discharge

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | @ 1 ft. of Head | @ 3 ft. of Head | @ 4 ft. of Head | @ 5 ft. of Head | Max. Viscosity, cP | Air Consumption, ft³/min | Air Tube Connection | Intake Tube Connection | Discharge Tube Connection | Diaphragm Material | Lg. | Wd. | Ht. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

15 ft. Maximum Feet of Head—100 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 5 | 3.7 | 2.9 | 1.8 | 700 | 1.75 | 1/4" Barbed Male | 1/2" Male | 1/2" Male | Fluoroelastomer | 4 9/16" | 1 13/16" | 5 13/16" | 2753N12 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Drum Pumps for Water, Oil, Coolants, and Chemicals

With NPT Discharge

Temp., ° F | Intake | Discharge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Gender | Pipe Size | Each | ||

| 14 | 55 | 1,500 | -30 | 300 | 40 to 80 | 27 | 2 NPT | Drum Connector | 1/8 Female NPT | 1 1/2" | 39" | Female | 3/4 | 42905K74 | 0000000 | |

With Tube-End Discharge

Temp., ° F | Intake | Discharge (Tube End) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | ID | Lg., ft. | Each | ||

| 15 | 30 | 300 | 35 | 150 | 40 | 27 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 1/4" | 27" | 3/4" | 5 | 8165K7 | 0000000 | |

Aluminum Long-Life Air-Powered Drum Pumps for Oil

Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Connection | Pipe Size | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 31 | 55 | 8,000 | 10 | 180 | 100 | 40 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 3/4 Female NPT | 39" | Pump Body | Threaded | 3/4 Female NPT | 8281K13 | 000000000 | 8281K131 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Constant-Flow-Rate Piston Pumps

Flow Rate, gpm | Air Pressure, psi | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

@ 0 psi | @ 3,000 psi | Max. ft. of Head, ft. | Max. Discharge Pressure, psi | Max. Viscosity, cP | Min. | Max. | Air Consumption, scfm | Air Connection (NPT) | Intake Pipe Connection (NPT) | Discharge Pipe Connection (NPT) | Lg. | Wd. | Ht. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

86:1 Discharge Liquid to Inlet Air Pressure Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.19 | 0.17 | 28,764 | 12,470 | 100 | 15 | 145 | 20 | 1/4 Female | 3/8 Female | 1/4 Female | 4 5/8" | 4" | 9" | 6770K43 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

28:1 Discharge Liquid to Inlet Air Pressure Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.58 | 0.13 | 9,365 | 4,060 | 100 | 15 | 145 | 20 | 1/4 Female | 3/8 Female | 1/4 Female | 4 5/8" | 4" | 9" | 6770K41 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

11:1 Discharge Liquid to Inlet Air Pressure Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.76 | — | 3,679 | 1,595 | 100 | 15 | 145 | 45 | 1/2 Female | 1 Female | 1/2 Female | 10 3/4" | 9 1/2" | 10 3/8" | 6770K28 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Air-Powered Double Diaphragm Pumps for Oil

Threaded Bottom Intake and Threaded Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 40 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity, cP | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

231 ft. Maximum Feet of Head—100 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 12 | 8 | 5 | 1/8" | 10,000 | 16 | 1/4 Female NPT | 1/2 Female NPT, 1 Male NPT | 1/2 Female NPT, 1 Male NPT | 7" | 10" | 12" | 4157K133 | 000000000 | 3781K72 | 0000000 | 3781K96 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 23 | 19 | 13 | 8 | 5/32" | 10,000 | 20 | 1/4 Female NPT | 3/4 Female NPT, 1 1/2 Male NPT | 3/4 Female NPT, 1 1/2 Male NPT | 7" | 12" | 13" | 4157K134 | 00000000 | 3781K72 | 000000 | 3781K73 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Oil-Dispensing Pump Systems

Panel | For Max. Viscosity | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pumps | Cap. | oz. per Cycle, fl. oz. | Dispensing Interval | Max. Oil Outlet Pressure, psi | Ht. | Wd. | Reservoir Material | Pump Material | Air Inlet Pressure, psi | Air Inlet Gender | For Air Inlet Tube OD | Voltage, V AC | Current, amp | Temp. Range, ° F | Mounting Fasteners Included | ISO Grade | SAE Grade | SSU Grade, SSU | AGMA Grade | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Female Oil Outlets | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 16 fl. oz. | 0 to 0.007 | 0.6 sec. to 24 hr. | 1,080 | 10 3/4" | 10 7/8" | Plastic | Aluminum | 40 to 120 | Female | 1/4" | 120 | 0.06 | -15 to 180 | No | 220 | 90 | 1,000 | 5 | 2420K1 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1 qt. | 0 to 0.007 | 0.6 sec. to 24 hr. | 1,080 | 10 3/4" | 10 7/8" | Plastic | Aluminum | 40 to 120 | Female | 1/4" | 120 | 0.06 | -15 to 180 | No | 220 | 90 | 1,000 | 5 | 2420K2 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Smooth-Flow Air-Powered Double Diaphragm Pumps

Barbed Bottom Intake and Barbed Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | Max. Viscosity, cP | Air Consumption, ft³/min | Air Tube Connection | Intake Tube Connection | Discharge Tube Connection | Diaphragm Material | Lg. | Wd. | Ht. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

135 ft. Maximum Feet of Head—58 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.6 | 0.5 | 0.4 | 2,500 | 0.48 | 1/4" Barbed Male | 3/8" Male | 3/8" Male | Buna-N | 4" | 6" | 6" | 4022K47 | 0000000 | 4022K12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.6 | 0.5 | 0.4 | 2,500 | 0.48 | 1/4" Barbed Male | 3/8" Male | 3/8" Male | Fluoroelastomer | 4" | 6" | 6" | 4022K36 | 000000 | 4022K11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

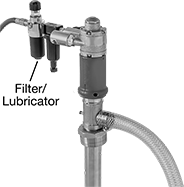

Air-Powered Drum Pumps with Hose and Filter/Lubricator for Water, Oil, Coolants, and Chemicals

Pumps | Pump Repair Kits | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | ||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Tube ID | Tube Lg., ft. | Tube Material | Features | Each | Each | ||||

| 16 | 55 | 2,000 | -20 | 150 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 1/2" | 40" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 8243K21 | 000000000 | 8243K62 | 0000000 | ||

| 16 | 55 | 2,000 | 35 | 150 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 5/8" | 40" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 8243K31 | 00000000 | 8243K62 | 000000 | ||

| 22 | 55 | 330 | 35 | 160 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 2" | 40" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 4296K41 | 00000000 | ——— | 0 | ||

| 22 | 55 | 330 | 35 | 160 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 2" | 48" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 4296K48 | 00000000 | ——— | 0 | ||

Aluminum Air-Powered Double Diaphragm Pumps for Oil, Chemicals, and Fuel

Threaded Bottom Intake and Threaded Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity, cP | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

289 ft. Maximum Feet of Head—125 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 12 | 10 | 7 | 1/8" | 10,000 | 20 | 1/4 Female NPT | 1/2 Female NPT, 1/2 Female NPT | 1/2 Female NPT, 1/2 Female NPT | 9" | 10" | 12" | 9948K16 | 000000000 | 9948K58 | 0000000 | 3781K52 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 38 | 30 | 19 | 1/4" | 20,000 | 40 | 1/2 Female NPT | 1 Female NPT | 1 Female NPT | 13" | 10" | 13" | 9948K19 | 00000000 | 3781K68 | 000000 | 3781K47 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 106 | 77 | 62 | 45 | 1/4" | 30,000 | 50 | 3/4 Female NPT | 1 1/2 Female NPT | 1 1/2 Female NPT | 15" | 17" | 22" | 9948K21 | 00000000 | 3781K63 | 000000 | 3781K44 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 104 | 76 | 53 | 1/4" | 40,000 | 100 | 3/4 Female NPT | 2 Female NPT | 2 Female NPT | 15" | 17" | 26" | 9948K23 | 00000000 | 3781K63 | 000000 | 3781K19 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 235 | 174 | 127 | 90 | 3/8" | 50,000 | 140 | 3/4 Female NPT | 3 Female NPT | 3 Female NPT | 17" | 20" | 32" | 9948K24 | 00000000 | 3781K63 | 000000 | 3781K39 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVDF Long-Life Air-Powered Drum Pumps for Chemicals

Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Connection | Pipe Size | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 55 | 3,000 | 40 | 210 | 100 | 12 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 1/2 Female NPT | 36" | Pump Body | Threaded | 1/2 Female NPT | 2534K54 | 000000000 | 8281K111 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Air-Powered Double Diaphragm Pumps for Oil and Chemicals

Threaded Bottom Intake and Threaded Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity, cP | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

289 ft. Maximum Feet of Head—125 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 12 | 10 | 7 | 1/8" | 10,000 | 20 | 1/4 Female NPT | 1/2 Female NPT | 1/2 Female NPT | 9" | 10" | 12" | 9948K27 | 000000000 | 9948K58 | 0000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 38 | 30 | 19 | 1/4" | 20,000 | 40 | 1/2 Female NPT | 1 Female NPT | 1 Female NPT | 13" | 10" | 13" | 9948K18 | 00000000 | 3781K68 | 000000 | 3781K46 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 106 | 77 | 62 | 45 | 1/4" | 30,000 | 50 | 3/4 Female NPT | 1 1/2 Female NPT | 1 1/2 Female NPT | 15" | 17" | 22" | 9948K22 | 00000000 | 3781K63 | 000000 | 3781K43 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 235 | 174 | 127 | 90 | 3/8" | 50,000 | 140 | 3/4 Female NPT | 3 Female NPT | 3 Female NPT | 17" | 20" | 32" | 9948K26 | 00000000 | 3781K63 | 000000 | 3781K38 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Air-Powered Grease-Dispensing Pumps

Grease Outlet | Overall | Air Inlet | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Grease Outlets | Cap., fl. oz. | oz. per Cycle, fl. oz. | For NLGI Consistency Grade | Max. Grease Outlet Pressure, psi | Thread Type | Pipe Size | Gender | Ht. | Wd. | Max. Distance from Lubrication Point, ft. | Loading Method | Thread Type | Pipe Size | Gender | Each | ||

| 1 | 1 1/2 | 0 to 0.007 | 00, 0, 1, 2 | 1,080 | NPT | 1/8 | Female | 8 5/16" | 3 1/4" | 3 | Grease Gun | NPT | 1/8 | Female | 2279K21 | 0000000 | |

| 2 | 1 1/2 | 0 to 0.007 | 00, 0, 1, 2 | 1,080 | NPT | 1/8 | Female | 8 5/16" | 4 1/2" | 3 | Grease Gun | NPT | 1/8 | Female | 2279K22 | 000000 | |

| 4 | 1 1/2 | 0 to 0.007 | 00, 0, 1, 2 | 1,080 | NPT | 1/8 | Female | 8 5/16" | 7" | 3 | Grease Gun | NPT | 1/8 | Female | 2279K23 | 000000 | |

| 6 | 1 1/2 | 0 to 0.007 | 00, 0, 1, 2 | 1,080 | NPT | 1/8 | Female | 8 5/16" | 9 1/2" | 3 | Grease Gun | NPT | 1/8 | Female | 2279K24 | 000000 | |

316 Stainless Steel Air-Powered Double Diaphragm Pumps for Chemicals, Fuel, and Flammable Liquids

Threaded Bottom Intake and Threaded Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity, cP | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

289 ft. Maximum Feet of Head—125 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 12 | 10 | 7 | 1/8" | 10,000 | 20 | 1/4 Female NPT | 1/2 Female NPT | 1/2 Female NPT | 9" | 10" | 10" | 41655K27 | 000000000 | 9948K58 | 0000000 | 3781K52 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 38 | 30 | 19 | 1/4" | 20,000 | 40 | 1/2 Female NPT | 1 Female NPT | 1 Female NPT | 13" | 10" | 13" | 41655K28 | 00000000 | 3781K68 | 000000 | 3781K47 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 106 | 77 | 62 | 45 | 1/4" | 30,000 | 50 | 3/4 Female NPT | 1 1/2 Female NPT | 1 1/2 Female NPT | 15" | 17" | 22" | 41655K29 | 00000000 | 3781K63 | 000000 | 3781K44 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 104 | 76 | 53 | 1/4" | 40,000 | 100 | 3/4 Female NPT | 2 Female NPT | 2 Female NPT | 15" | 17" | 26" | 41655K31 | 00000000 | 3781K63 | 000000 | 3781K19 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 235 | 174 | 127 | 90 | 3/8" | 50,000 | 140 | 3/4 Female NPT | 3 Female NPT | 3 Female NPT | 17" | 20" | 32" | 41655K32 | 000000000 | 3781K63 | 000000 | 3781K39 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Air-Powered Double Diaphragm Pumps for Harsh Chemicals

Threaded Side Intake and Threaded Side Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | Max. Solids Dia. | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

231 ft. Maximum Feet of Head—100 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | 0.06" | 4.8 | 1/8 Female NPT | 1/4 Female NPT | 1/4 Female NPT | 3 3/8" | 5 1/2" | 6 1/2" | 2925N1 | 000000000 | 2666N28 | 0000000 | 2666N21 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.7 | 0.08" | 9.3 | 1/8 Female NPT | 3/8 Female NPT | 3/8 Female NPT | 3 1/2" | 5 7/8" | 7 5/8" | 2925N2 | 00000000 | 2666N29 | 000000 | 2666N22 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 0.16" | 29 | 1/4 Female NPT | 1/2 Female NPT | 1/2 Female NPT | 6" | 9 3/16" | 8" | 2925N3 | 00000000 | 2666N31 | 000000 | 2666N23 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 39 | 0.24" | 46 | 1/4 Female NPT | 1 Female NPT | 1 Female NPT | 8" | 10 7/8" | 10 3/8" | 2925N4 | 00000000 | 2666N32 | 000000 | 2666N24 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Container-Mount Grease Dispensers

For 35 lb. Pail

Dispensers | Replacement Follower Plates | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Container | Air Inlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Max. Dia. | Max. Ht. | For NLGI Consistency Grade | Flow Rate, fl oz/min | Container Included | Max. Grease Outlet Pressure, psi | Max. Grease Outlet Pressure with Booster, psi | Grease Outlet Hose Lg., ft. | Material | Max. Pressure, psi | Thread Type | Pipe Size | Gender | For Grease Fitting Style | Includes | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Booster Gun | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 12 3/16" | 12 13/16" | 00, 0, 1, 2 | 16 | No | 7,500 | 10,000 | 13 | Steel | 150 | NPT | 1/4 | Female | Standard | Cover Follower Plate Four-Wheel Dolly Grease Outlet Hose Gun Pump Z-Swivel | 1384K11 | 0000000 | 1384K87 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 12" | 16 9/16" | 00, 0, 1, 2 | 64 | No | 7,500 | 10,000 | 10 | Steel | 150 | NPT | 1/4 | Female | Standard | Cover Follower Plate Grease Outlet Hose Gun Pump Z-Swivel | 13585K51 | 00000000 | 1033K57 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Standard Gun | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 12" | 16 9/16" | 00, 0, 1, 2 | 32 | No | 7,500 | — | 10 | Steel | 150 | NPTF | 1/4 | Female | Standard | Cover Follower Plate Grease Outlet Hose Gun Pump Z-Swivel | 1033K52 | 00000000 | 1033K57 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 120 lb. Drum

|  |  |  |

Style A | Style C | Style D |

Dispensers | Replacement Follower Plates | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Container | Air Inlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Max. Dia. | Max. Ht. | For NLGI Consistency Grade | Flow Rate, fl oz/min | Container Included | Max. Grease Outlet Pressure, psi | Max. Grease Outlet Pressure with Booster, psi | Grease Outlet Hose Lg., ft. | Material | Max. Pressure, psi | Thread Type | Pipe Size | Gender | For Grease Fitting Style | Includes | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Booster Gun | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 15 15/16" | 26" | 00, 0, 1, 2 | 16 | No | 7,500 | 10,000 | 13 | Steel | 150 | NPT | 1/4 | Female | Standard | Cover Follower Plate Four-Wheel Dolly Grease Outlet Hose Gun Pump Z-Swivel | 1384K13 | 000000000 | 1384K92 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 14 7/8" | 27 1/4" | 00, 0, 1, 2 | 64 | No | 7,500 | 10,000 | 10 | Steel | 150 | NPT | 1/4 | Female | Standard | Cover Follower Plate Four-Wheel Dolly Grease Outlet Hose Gun Pump Z-Swivel | 13585K52 | 00000000 | 1033K58 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 14 7/8" | 27 1/4" | 00, 0, 1, 2 | 64 | No | 7,500 | 10,000 | 10 | Steel | 150 | NPT | 1/4 | Female | Standard | Cover Follower Plate Grease Outlet Hose Gun Pump Two-Wheel Hand Truck Z-Swivel | 13585K53 | 00000000 | 1033K58 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Standard Gun | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 14 7/8" | 27 1/4" | 00, 0, 1, 2 | 32 | No | 7,500 | — | 10 | Steel | 150 | NPTF | 1/4 | Female | Standard | Cover Follower Plate Four-Wheel Dolly Grease Outlet Hose Gun Pump Z-Swivel | 1033K53 | 00000000 | 1033K58 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 14 7/8" | 27 1/4" | 00, 0, 1, 2 | 32 | No | 7,500 | — | 10 | Steel | 150 | NPTF | 1/4 | Female | Standard | Cover Follower Plate Grease Outlet Hose Gun Pump Two-Wheel Hand Truck Z-Swivel | 1033K54 | 00000000 | 1033K58 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 400 lb. Drum

Dispensers | Replacement Follower Plates | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Container | Grease Outlet | Air Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Max. Dia. | Max. Ht. | For NLGI Consistency Grade | Flow Rate, fl oz/min | Container Included | Max. Grease Outlet Pressure, psi | Hose Lg., ft. | Thread Type | Pipe Size | Gender | Material | Max. Pressure, psi | Hose Lg., ft. | Thread Type | Pipe Size | Gender | For Grease Fitting Style | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No Gun | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 23 5/8" | 36 13/16" | 00, 0, 1, 2 | 64 | No | 7,500 | 4 | NPT | 3/8 | Male | Steel | 150 | 3 | NPT | 1/4 | Female | Standard | Air Inlet Hose Cover Follower Plate Grease Outlet Hose Pump | 13585K54 | 000000000 | 1033K59 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Pistol-Grip Grease Guns

Nozzle | Nozzle Connection | Air Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., fl. oz. | Flow Rate, fl oz/min | Strokes per oz. | For NLGI Consistency Grade | Max. Grease Outlet Pressure, psi | Lg. | Material | Thread Type | Pipe/Thread Size | Gender | Pressure, psi | Thread Type | Pipe Size | Gender | Loading Method | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Standard Grease Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 10 | 29 | 000, 00, 0, 1, 2, 3 | 6,000 | 30" | Nylon | NPT UNEF | 1/8 7/16"-28 | Male Male | 40 to 150 | NPS | 1/4 | Female | Bulk Filler Pump, Cartridge, Hand Pack, Suction | 1454K38 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Drum Pumps for Flammable Liquid

Temp., ° F | Intake | Discharge (Pump Body) | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Connection | For Tube ID | Gender | Certification | Features | Each | |||

| 26 | 55 | 1,100 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 39" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 2824K39 | 000000000 | ||

| 26 | 55 | 1,100 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 47" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 2824K49 | 00000000 | ||

| 53 | 55 | 1,000 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 39" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 8252K12 | 00000000 | ||

| 53 | 55 | 1,000 | -40 | 210 | 44 to 87 | 53 | 2 NPT | Drum Connector | 3/8 Female NPT | 1 5/8" | 47" | Pump Body | Barbed | 1" | Male | CE Marked | Bonding and Grounding Wires, Hanger | 8252K14 | 00000000 | ||

Aluminum Air-Powered Double Diaphragm Pumps for Fuel, Oil, and Large Solids

Threaded Top Intake and Threaded Bottom Discharge

|  |

70 gpm Maximum Flow Rate | 140 gpm Maximum Flow Rate |

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

289 ft. Maximum Feet of Head—125 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 47 | 35 | 20 | 1" | Not Rated | 50 | 1/2 Female NPT | 1 Female NPT | 1 Female NPT | 11" | 17" | 16" | 8090K13 | 000000000 | 3781K58 | 0000000 | 8090K42 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 140 | 120 | 96 | 77 | 2" | Not Rated | 150 | 3/4 Female NPT | 2 Female NPT | 2 Female NPT | 14" | 22" | 20" | 8090K25 | 00000000 | 3781K57 | 000000 | 3781K16 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pump Pulsation Dampers for Air-Powered Transfer Pumps

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Intake Pipe Connections (NPT) | Air Connection (NPT) | Housing Material | Dia. | Ht. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Bottom Intake | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ½ Female | ⅛ Female | 316L Stainless Steel | 10 5/8" | 6 7/16" | 1 NPT to 1/2 NPT Adapter | 3062N22 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ¾ Female | ⅛ Female | 316L Stainless Steel | 10 5/8" | 6 7/16" | 1 NPT to 3/4 NPT Adapter | 3062N21 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 Female | ⅛ Female | 316L Stainless Steel | 10 5/8" | 6 7/16" | — | 3062N11 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 ½ Female | ⅛ Female | 316L Stainless Steel | 13 3/4" | 8 3/16" | — | 3062N12 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 Female | ⅛ Female | 316L Stainless Steel | 13 3/4" | 8 3/16" | — | 3062N13 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Air-Powered Double Diaphragm Pumps for Oil, Chemicals, Fuel, and Large Solids

Threaded Top Intake and Threaded Bottom Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

289 ft. Maximum Feet of Head—125 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 47 | 35 | 20 | 1" | Not Rated | 50 | 1/2 Female NPT | 1 Female NPT | 1 Female NPT | 11" | 17" | 16" | 2785K63 | 000000000 | 3781K58 | 0000000 | 8090K42 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Air-Powered Double Diaphragm Pumps for Oil, Chemicals, and Large Solids

Threaded Top Intake and Threaded Bottom Discharge

|  |

70 gpm Maximum Flow Rate | 140 gpm Maximum Flow Rate |

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

289 ft. Maximum Feet of Head—125 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 47 | 35 | 20 | 1" | Not Rated | 50 | 1/2 Female NPT | 1 Female NPT | 1 Female NPT | 11" | 17" | 16" | 8090K11 | 000000000 | 3781K58 | 0000000 | 8090K41 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 140 | 120 | 96 | 77 | 2" | Not Rated | 150 | 3/4 Female NPT | 2 Female NPT | 2 Female NPT | 14" | 22" | 20" | 8090K22 | 00000000 | 3781K57 | 000000 | 3781K17 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flanged Top Intake and Flanged Bottom Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Flange | Bolt | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 80 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | OD | Thk. | Pressure Class | Circle Dia. | Hole Dia. | Lg. | Wd. | Ht. | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

289 ft. Maximum Feet of Head—125 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 260 | 178 | 150 | 118 | 3" | Not Rated | 120 | 3/4 Female NPT | 3 | 3 | 7 1/2" | 7/8" | 150 | 6" | 5/8" | 16" | 37" | 30" | 8090K33 | 000000000 | 3781K57 | 0000000 | 3781K22 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||