About On/Off Valves

More

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Low-Pressure Stainless Steel Threaded Pipe Flanges

Also known as Pressure Class 150 flanges, these are designed for low-pressure pipe applications. Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a gasket (sold separately) to create an access point within a line. Alloy 20 stainless steel flanges have the best corrosion resistance of all the stainless steel flanges we offer. Alloy 20 stainless steel is also known as Carpenter 20 and resists cracking from stress and corrosion.

Forged flanges have better strength than cast flanges. They are also called ANSI flanges.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met:

Alloy 20 flanges: ASME B16.5

All other flanges: ASME B16.5, ASTM A182 - Fittings: Use Class 150 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

Bolt Hole | Alloy 20 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Each | |

NPT | |||||||||

| 1/2 | 3 1/2" | 1/2" | 0.62" | 4 | 2 3/8" | 290 psi @ 72° F | 200 psi @ 360° F | 0000000 | 000000 |

| 3/4 | 3 7/8" | 1/2" | 0.62" | 4 | 2 3/4" | 290 psi @ 72° F | 200 psi @ 360° F | 0000000 | 000000 |

| 1 | 4 1/4" | 1/2" | 0.62" | 4 | 3 1/8" | 290 psi @ 72° F | 200 psi @ 360° F | 0000000 | 000000 |

| 1 1/2 | 5" | 1/2" | 0.62" | 4 | 3 7/8" | 290 psi @ 72° F | 200 psi @ 360° F | 0000000 | 000000 |

| 2 | 6" | 5/8" | 0.75" | 4 | 4 3/4" | 290 psi @ 72° F | 200 psi @ 360° F | 0000000 | 000000 |

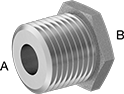

Medium-Pressure Stainless Steel Threaded Pipe Fittings

Choose these fittings when you want the same high-quality found in our low-pressure pipe fittings, but need more strength to handle higher pressures.

316 stainless steel fittings have excellent corrosion resistance.

Alloy 20 stainless steel fittings have the best corrosion resistance of all the stainless steel fittings we offer. Alloy 20 stainless steel is also known as Carpenter 20 and resists cracking from stress and corrosion.

- For Use With: Air, Water, Steam

- Pressure Class: Not Rated

- Specifications Met: ASTM B366, ASME B16.9

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

- For Use With: Air, Water, Steam

- Pressure Class: Not Rated

- Specifications Met: ASTM B366, ASME B16.9

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

Metal Barbed Hose Fittings for Chemicals and Petroleum

Made of stainless steel, these fittings stand up to a wide variety of chemicals, as well as fuels, gasoline, and oils. To connect, slide the barbed end into plastic or rubber hose and secure with a clamp.

Adapters are also known as hose nipples; they adapt a barbed end to a threaded end.

Alloy 20 stainless steel fittings resist corrosion better than any other stainless steel hose fitting we offer. They contain nickel, so they withstand exposure to harsh chemicals, such as sulfuric, phosphoric, and nitric acids. Commonly known as Carpenter 20 fittings, they also resist cracking from stress.

- For Use With: See table

- Maximum Pressure: See table

- Temperature Range: See table

- Attachment Type: Use Band-and-Buckle Clamps

| For Hose ID | Pipe Size | Max. Pressure | Temperature Range, °F | For Use With | Each | |

Alloy 20 Stainless Steel | ||||||

|---|---|---|---|---|---|---|

| 1/4" | 1/4 | 300 psi @ 72° F | -40° to 300° | Acetone, Boric Acid, Citric Acid, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits, Vegetable Oil | 000000000 | 0000000 |

| 3/8" | 1/4 | 300 psi @ 72° F | -40° to 300° | Acetone, Boric Acid, Citric Acid, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits, Vegetable Oil | 000000000 | 000000 |

| 3/8" | 3/8 | 300 psi @ 72° F | -40° to 300° | Acetone, Boric Acid, Citric Acid, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits, Vegetable Oil | 000000000 | 000000 |

| 1/2" | 1/2 | 300 psi @ 72° F | -40° to 300° | Acetone, Boric Acid, Citric Acid, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits, Vegetable Oil | 000000000 | 000000 |

| 3/4" | 3/4 | 300 psi @ 72° F | -40° to 300° | Acetone, Boric Acid, Citric Acid, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits, Vegetable Oil | 000000000 | 000000 |

Ultra-Chemical-Resistant Threaded On/Off Valves

The most chemical-resistant threaded valves we offer, these have a PTFE seal and an alloy body that can withstand extremely aggressive and corrosive chemicals, such as methyl ethyl ketone and toluene. They are standard port, so they slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With: Acetone, Air, Butane, Carbon Dioxide, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Kerosene, Methanol, Methyl Ethyl Ketone, Nitrogen, Propane, Soap Solutions, Sodium Hydroxide, Toluene, Water, Xylene

- Ball Material: Alloy 20 Stainless Steel

- Seal Material: PTFE Plastic

- Seat Material: PTFE Plastic