Filter by

Screw Size

ID

Thickness

Washer Type

Color

Application

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Maximum Temperature

Specifications Met

Seal Hardness

Minimum Temperature

Sealing Washers

Metal

For Screw Size | ID | OD | Thk. | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.125" | 0.281" | 0.024" to 0.038" | — | 100 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.156" | 0.281" | 0.024" to 0.038" | — | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.174" | 0.312" | 0.024" to 0.038" | — | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.203" | 0.375" | 0.024" to 0.038" | — | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.260" | 0.500" | 0.043" to 0.057" | — | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.344" | 0.625" | 0.043" to 0.057" | — | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.406" | 0.656" | 0.055" to 0.069" | — | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.531" | 0.812" | 0.055" to 0.069" | — | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.688" | 0.938" | 0.071" to 0.086" | — | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.812" | 1.062" | 0.071" to 0.086" | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.062" | 1.375" | 0.086" to 0.104" | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.200 mm | 6.400 mm | 0.6 mm to 0.9 mm | — | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.300 mm | 8.000 mm | 0.8 mm to 1.2 mm | — | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.200 mm | 9.000 mm | 0.8 mm to 1.2 mm | — | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.200 mm | 9.900 mm | 0.8 mm to 1.2 mm | DIN 7603 | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.200 mm | 11.900 mm | 0.8 mm to 1.2 mm | DIN 7603 | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.200 mm | 11.900 mm | 0.8 mm to 1.2 mm | DIN 7603 | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.200 mm | 13.900 mm | 0.8 mm to 1.2 mm | DIN 7603 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.200 mm | 13.900 mm | 0.8 mm to 1.2 mm | DIN 7603 | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.200 mm | 13.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.200 mm | 15.900 mm | 0.8 mm to 1.2 mm | DIN 7603 | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.200 mm | 15.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 12.200 mm | 15.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 12.200 mm | 17.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 | 14.200 mm | 17.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 | 14.200 mm | 19.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 16.200 mm | 19.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 16.200 mm | 21.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 | 18.200 mm | 21.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 | 18.200 mm | 23.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 20.200 mm | 23.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 20.200 mm | 25.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M22 | 22.200 mm | 26.900 mm | 1.3 mm to 1.7 mm | DIN 7603 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 24.300 mm | 29.900 mm | 1.8 mm to 2.2 mm | DIN 7603 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 24.300 mm | 31.900 mm | 1.8 mm to 2.2 mm | DIN 7603 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M26 | 26.300 mm | 31.900 mm | 1.8 mm to 2.2 mm | DIN 7603 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M27 | 30.000 mm | 38.000 mm | 2.8 mm to 3.2 mm | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 | 33.000 mm | 42.000 mm | 2.8 mm to 3.2 mm | — | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M36 | 39.000 mm | 47.500 mm | 2.8 mm to 3.2 mm | — | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M42 | 45.000 mm | 53.000 mm | 2.8 mm to 3.2 mm | — | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bonded Sealing Washers

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID | OD | Thk. | Min. | Max. | Color | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum and Neoprene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.200" | 0.500" | 0.090" to 0.120" | -40 | 250 | Black | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 12 | 0.240" | 0.500" | 0.090" to 0.120" | -40 | 250 | Black | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 14 | 0.275" | 0.625" | 0.090" to 0.120" | -40 | 250 | Black | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.275" | 0.625" | 0.119" to 0.154" | -40 | 250 | Black | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.330" | 0.625" | 0.110" to 0.145" | -40 | 250 | Black | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.330" | 0.680" | 0.119" to 0.154" | -40 | 250 | Black | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.434" | 0.735" | 0.116" to 0.151" | -40 | 250 | Black | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.434" | 0.810" | 0.121" to 0.156" | -40 | 250 | Black | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.532" | 1.000" | 0.109" to 0.144" | -40 | 250 | Black | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealing Washer Assortments

|

No. of Pieces | Sizes Included | Specs. Met | Container Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 570 | For M6 to M30 Screw Sizes | DIN 7603 | Plastic Box | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

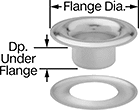

Fabric Grommets

Standard Washer

Grommet Trade Size | For Max. Material Thk. | ID | Flange Dia. | Dp. Under Flange | For Use Outdoors | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 00 | 0.063" | 3/16" | 0.425" | 0.135" | Yes | 50 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 | 0.101" | 1/4" | 0.545" | 0.175" | Yes | 50 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 0.108" | 9/32" | 0.687" | 0.185" | Yes | 50 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 0.14" | 3/8" | 0.815" | 0.215" | Yes | 50 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 0.219" | 7/16" | 0.97" | 0.295" | Yes | 50 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 0.298" | 1/2" | 1.05" | 0.374" | Yes | 50 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealing Grommets

|  |  | |

Style 1 | Style 2 | Style 3 | Style 4 |

Style 1

Mounting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | Flange Dia. | Overall Ht. | Temp., ° F | For Use Outdoors | Color | No. of Holes | Fasteners Included | Hole Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Resistant Buna-N with Aluminum Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | 3" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | 3" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.375" | 3" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5" | 3" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 3" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.75" | 3" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 4" | 0.1" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.125" | 3" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.25" | 3" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5" | 4 1/2" | 0.29" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.797" | 4" | 0.1" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.110" | 4 1/2" | 0.29" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 3

Mounting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | Flange Dia. | Overall Ht. | Temp., ° F | For Use Outdoors | Color | No. of Holes | Fasteners Included | Hole Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Resistant Buna-N with Aluminum Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/32" | 2" | 1.15" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 4

Mounting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | Flange Dia. | Overall Ht. | Temp., ° F | For Use Outdoors | Color | No. of Holes | Fasteners Included | Hole Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Resistant Buna-N with Aluminum Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/32" | 3" | 1.35" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Split Sealing Grommets

Mounting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | Flange Dia. | Overall Ht. | Temp., ° F | For Use Outdoors | Color | No. of Holes | Fasteners Included | Hole Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Resistant Buna-N with Aluminum Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 3" | 0.035" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 3" | 0.035" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/8" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cut-to-Size Sealing Grommets

|  | |

Style 1 | Style 2 | Style 3 |

Style 1

Mounting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | Flange Dia. | Overall Ht. | Temp., ° F | For Use Outdoors | Color | No. of Holes | Fasteners Included | Hole Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Resistant Buna-N with Aluminum Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" to 3/4" | 1 1/2" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" to 1" | 2" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" to 1 1/2" | 3" | 0.16" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" to 2" | 4" | 0.1" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" to 4" | 6" | 0.19" | -20 to 220 | Yes | Black | 4 | No | 1/8" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 2

Flange | Mounting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | Lg. | Wd. | Overall Ht. | Temp., ° F | For Use Outdoors | Color | No. of Holes | Fasteners Included | Hole Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Resistant Buna-N with Aluminum Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" to 2" | 5 1/4" | 3" | 0.16" | -20 to 220 | Yes | Black | 8 | No | 1/8" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cut-to-Size Split Sealing Grommets

Mounting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | Flange Dia. | Overall Ht. | Temp., ° F | For Use Outdoors | Color | No. of Holes | Fasteners Included | Hole Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Resistant Buna-N with Aluminum Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" to 1" | 2" | 0.14" | -20 to 220 | Yes | Black | 4 | No | 0.14" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" to 1 3/4" | 3" | 0.14" | -20 to 220 | Yes | Black | 6 | No | 0.14" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" to 2 7/8" | 4 1/2" | 0.13" | -20 to 220 | Yes | Black | 6 | No | 0.13" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||