Filter by

Solder Type

System of Measurement

Melting Temperature

Environment

Performance

Application

Length

Formulation

DFARS Specialty Metals

Handle Material

Solder for Drinking Water

Material Composition | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Tin | Silver | Copper | Lead | Melting Temp., ° F | Solder Type | Dia. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Aluminum, Brass, Bronze, Copper, Nickel, Stainless Steel, Steel, and Zinc Alloy | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sn95Cu4.8Ag0.2 | 95% | 0.2% | 4.8% | 0% | 440 | Lead-Free, Flux Required | 0.118" | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No-Flux Solder for Aluminum

Lead-Free, No Flux Required

|

Material Composition | 2 lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Zinc | Aluminum | Lead | Dia. | Melting Temp., ° F | Lg. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Zn98Al2 | 98% | 2% | 0% | 0.125" | 760 | 18" | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Melting-Point Solder for Low-Temperature Applications

Leaded, Flux Required

Material Composition | 0.16 oz. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Indium | Silver | Lead | Dia. | Melting Temp., ° F | Thermal Conductivity, W/(m⋅°C) | Tensile Strength, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Aluminum, Brass, Bronze, Ceramic, Glass, Gold, Nickel, Quartz, Stainless Steel, Steel, and Zinc Alloy | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In80Pb15Ag5 | 80% | 5% | 15% | 0.030" | 310 | 43 | 2,550 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lead-Free, Flux Required

Material Composition | 0.11 oz. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Indium | Tin | Lead | Dia. | Melting Temp., ° F | Thermal Conductivity, W/(m⋅°C) | Tensile Strength, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Aluminum, Brass, Bronze, Ceramic, Glass, Nickel, Quartz, Stainless Steel, Steel, and Zinc Alloy | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In52Sn48 | 52% | 48% | 0% | 0.030" | 245 | 34 | 1,720 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In100 | 100% | — | 0% | 0.030" | 315 | 86 | 270 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Density Low-Melting-Point Solder

Solder for Aluminum

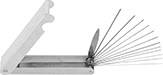

Desoldering Iron Nozzle Tip Cleaners

|

No. of Cleaners | Cleaner Dia. | Lg. | Material | Case Material | Each | ||

|---|---|---|---|---|---|---|---|

| 12 | 0.019" to 0.065" | 4 7/8" | Aluminum | Aluminum | 0000000 | 000000 |

Low-Melting-Point Solder Ribbon for Low-Temperature Applications

Leaded, Flux Required

Material Composition | 0.1 oz. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Indium | Silver | Lead | Melting Temp., ° F | Thermal Conductivity, W/(m⋅°C) | Tensile Strength, psi | Lg. | Wd. | Thk. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Aluminum, Brass, Bronze, Ceramic, Glass, Gold, Nickel, Quartz, Stainless Steel, Steel, and Zinc Alloy | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In80Pb15Ag5 | 80% | 5% | 15% | 310 | 43 | 2,550 | 12" | 1" | 0.002" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lead-Free, Flux Required

Material Composition | 0.1 oz. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Indium | Tin | Lead | Melting Temp., ° F | Thermal Conductivity, W/(m⋅°C) | Tensile Strength, psi | Lg. | Wd. | Thk. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Aluminum, Brass, Bronze, Ceramic, Glass, Gold, Nickel, Quartz, Stainless Steel, Steel, and Zinc Alloy | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In52Sn48 | 52% | 48% | 0% | 245 | 34 | 1,720 | 12" | 1" | 0.002" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In100 | 100% | — | 0% | 315 | 86 | 270 | 12" | 1" | 0.002" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brazing Alloys for Joining Aluminum to Copper

Material Composition | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc | Aluminum | Cadmium | Melting Temp. Range, ° F | Braze Type | Dia. | Lg. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Aluminum, Brass, Bronze, and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85% | 15% | 0% | 720 to 845 | Flux Required, Without Cadmium | 5/64" | 20" | 13 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flux-Included Brazing Alloys for Joining Aluminum to Copper

Material Composition | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc | Aluminum | Cadmium | Melting Temp. Range, ° F | Braze Type | Dia. | Lg. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Aluminum and Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 78% | 22% | 0% | 800 to 900 | Flux Core, Without Cadmium | 0.09" | 20" | 4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Soldering Flux for Aluminum

|

Container | ||||||||

|---|---|---|---|---|---|---|---|---|

For Joining | Size, fl. oz. | Type | Form | Cleanup Method | Mil. Spec. | Each | ||

| Aluminum | 4 | Jar | Paste | Water | DOD-STD-1866 | 000000 | 000000 | |

No-Flux Brazing Alloys for Aluminum

Conductive Adhesives for Electronics

Epoxy

Container | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mfr. Model No. | Size, fl. oz. | Net Wt., oz. | Type | Surface Resistivity | Begins to Harden | Reaches Full Strength | Thermal Conductivity, W/(m⋅°C) | Mix Ratio | Consistency | Max. Temp., ° F | Specs. Met | For Joining | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Loctite® | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2902 | — | 0.09 | Single-Use Packet, Syringe | 1× 10^-3Ω⋅cm | 60 min. | 24 hr. | 2.99 | 100:6 | Paste | 230 | ASTM E595 | Ceramic, Glass, Metal | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2902 | — | 0.35 | Single-Use Packet, Syringe | 1× 10^-3Ω⋅cm | 60 min. | 24 hr. | 2.99 | 100:6 | Paste | 230 | ASTM E595 | Ceramic, Glass, Metal | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Other Conductive Adhesives | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 0.09 | Single-Use Packet | 5× 10^-2Ω⋅cm | 3 hr. | 24 hr. | 1.55 | 1:1.15 | Paste | 230 | — | Ceramic, Glass, Metal | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.5 | — | Can | 4× 10^-4Ω⋅cm | 4 hr. | 5 day | 7.93 | 1:1 | Paste | 265 | — | Metal | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.5 | — | Can | 9× 10^-5Ω⋅cm | 4 hr. | 5 day | 7.9 | 1:1 | Paste | 175 | ASTM E595 | Ceramic, Glass, Metal | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | — | Can | 4× 10^-4Ω⋅cm | 4 hr. | 5 day | 7.93 | 1:1 | Paste | 265 | — | Metal | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | — | Can | 9× 10^-5Ω⋅cm | 4 hr. | 5 day | 7.9 | 1:1 | Paste | 175 | ASTM E595 | Ceramic, Glass, Metal | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brazing Alloys for Aluminum

Material Composition | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

AWS Material Code | Aluminum | Silicon | Cadmium | Melting Temp. Range, ° F | Braze Type | Dia. | Lg., ft. | Wt., oz. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BAlSi-4 | 88% | 12% | 0% | 1,070 to 1,080 | Flux Required, Without Cadmium | 1/16" | 10 | 0.75 | 1/3 oz. Tube of Flux | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BAlSi-3 | 90% | 10% | 0% | 970 to 1,085 | Flux Required, Without Cadmium | 3/64" | 33 | 1.1 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BAlSi-3 | 90% | 10% | 0% | 970 to 1,085 | Flux Required, Without Cadmium | 1/16" | 19 | 1.1 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pick Sets with Magnetic Retrievers

No. of Pieces | Includes | Max. Magnetic Pull, lbf | Overall Lg. | Grip Style | Handle Material | Container Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Straight Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 4 3/4" Lg. Steel Pick with Hook Tip and Knurled Grip 4 3/4" Lg. Steel Pick with 45° Angle Tip and Knurled Grip 4 3/4" Lg. Steel Pick with 90° Angle Tip and Knurled Grip 4 3/4" Lg. Steel Pick with Straight Tip and Knurled Grip | 1.5 | 4 3/4" | Knurled Head | Aluminum | Plastic Pouch | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Solder Mask

Dry Time | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Container Size, fl. oz. | Consistency | Touch, min. | Overall | Max. Temp., ° F | Mil. Spec. | For Use On | Color | Features | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wash-Away Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | Gel | 60 | 1 hr. | 640 | MIL-STD-2000 | Aluminum, Brass, Copper, Steel, Stainless Steel, Titanium, Gold, Silver | Blue | — | Outside United States and Canada | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | Gel | 60 | 2 hr. | 640 | — | Aluminum, Brass, Copper, Steel, Stainless Steel, Titanium, Gold, Silver | Red | Closed-Loop Compatible | Outside United States and Canada | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Peel-Away Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | Gel | 15 | 15 min. | 640 | MIL-STD-2000 | Aluminum, Brass, Steel, Stainless Steel, Titanium, Gold, Silver | White | — | Outside United States and Canada | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | Gel | 60 | 1 hr. | 640 | MIL-STD-2000 | Aluminum, Brass, Copper, Steel, Stainless Steel, Titanium, Gold, Silver | Red | — | Outside United States and Canada | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No-Clean Brazing Flux for Joining Aluminum to Copper

Picks with Magnetic Retriever

Handle Style | Overall Lg. | Max. Magnetic Pull, ozf | Grip Style | Material | Handle Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hook Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Straight | 7" | 6 | Knurled Head | Steel | Aluminum | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conductive Surface Fillers for Electronics

Container | Temp. Range, ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mfr. Model No. | Size, fl. oz. | Net Wt., oz. | Type | Begins to Harden | Reaches Full Strength | Consistency | Mixing Req. | Thermal Conductivity, W/(m⋅°C) | Electrical Volume Resistivity | Mix Ratio | Max. Thk. | For Use Outdoors | Min. | Max. | Color | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Loctite® Surface Fillers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3888 | — | 0.09 | Single-Use Packet | 90 min. | 24 hr. | Paste | Yes | 1.44 | 0.001Ω⋅cm | 100:6 | 1/4" | Yes | -40 | 170 | Silver | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Polycarbonate | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surface Fillers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 0.09 | Single-Use Packet | 90 min. | 24 hr. | Paste | Yes | 6.05 | 0.009Ω⋅cm | 100:6 | 1/4" | Yes | -75 | 250 | Silver | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Ceramic, Glass | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 0.35 | Single-Use Packet | 90 min. | 24 hr. | Paste | Yes | 6.05 | 0.009Ω⋅cm | 100:6 | 1/4" | Yes | -75 | 250 | Silver | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Ceramic, Glass | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 0.5 | — | Jar | 4 hr. | 5 day | Paste | Yes | 5.77 | 0.0004Ω⋅cm | 1:1 | Not Rated | No | Not Rated | 300 | Silver | Aluminum, Brass, Copper, Steel, Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 1 | — | Jar | 4 hr. | 5 day | Paste | Yes | 5.77 | 0.0004Ω⋅cm | 1:1 | Not Rated | No | Not Rated | 300 | Silver | Aluminum, Brass, Copper, Steel, Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brazing Flux for Aluminum

Soldering Flux for High-Temperature Aluminum

Conductive Surface Filler Pens for Electronics

Container | Tip | Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size, fl. oz. | Type | Dia. | Shape | Begins to Harden, min. | Reaches Full Strength, min. | Surface Resistivity, ohm/sq. | Consistency | Mixing Req. | Thermal Conductivity | Max. Thk. | For Use Outdoors | Min. | Max. | Color | For Use On | Cannot Be Sold To | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silver Epoxy | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.2 | Pen | 0.03" | Point | 3 | 60 | 0.050 | Thin Liquid | No | Not Rated | Not Rated | No | -65 | 300 | Silver | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium | Outside United States and Canada | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Small Parts Positioners

Changeable-Tip Pick Sets

No. of Pieces | Includes | Max. Magnetic Pull, ozf | Overall Lg. | Grip Style | Handle Material | Container Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Straight Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3 1/2" Lg. Aluminum Handle 3" Lg. Steel Hook Tip 3 1/2" Lg. Steel 90° Angle Tip 3 1/4" Lg. Steel 45° Angle Tip 3 1/4" Lg. Steel Straight Tip | 6 | 3" to 3 1/2" | Plain | Aluminum | Plastic Pouch | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two-Tip Picks

|

Hook Tip × 90° Angled Tip (shown open) |

Handle Style | Overall Lg. | Grip Style | Material | Handle Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hook Tip × 90° Angled Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Straight | 8" | Plain | Steel | Aluminum | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two-Tip Precision Picks

|  | |

Hook Tip × 90° Angled Tip | Hook Tip × Multiangle Tip | Straight Tip × 90° Angled Tip |

|  | |

Straight Tip × Multiangle Tip | 90° Angled Tip × Multiangle Tip |

Handle Style | Overall Lg. | Grip Style | Tip Dia. | Material | Handle Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hook Tip × 90° Angled Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Straight | 6 1/4" | Plain | 0.025" | 302 Stainless Steel | Aluminum | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hook Tip × Multiangle Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Straight | 6 1/4" | Plain | 0.025" | 302 Stainless Steel | Aluminum | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Tip × 90° Angled Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Straight | 6 1/4" | Plain | 0.025" | 302 Stainless Steel | Aluminum | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Tip × Multiangle Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Straight | 6 1/4" | Plain | 0.025" | 302 Stainless Steel | Aluminum | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90° Angled Tip × Multiangle Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Straight | 6 1/4" | Plain | 0.025" | 302 Stainless Steel | Aluminum | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Foil Conductive Tape

Temp., ° F | 15 ft. Long | 108 ft. Long | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Overall Thk. | Adhesive Type | Min. | Max. | Voltage Rating | Specs. Met | Color | Each | Each | |||

| 1/4" | 0.0036" | Acrylic | -40 | 325 | Not Rated | UL 510 | Silver | 000000000 | 00000 | 000000000 | 000000 | |

| 1/2" | 0.0036" | Acrylic | -40 | 325 | Not Rated | UL 510 | Silver | 000000000 | 0000 | 000000000 | 00000 | |

| 3/4" | 0.0036" | Acrylic | -40 | 325 | Not Rated | UL 510 | Silver | 000000000 | 00000 | 000000000 | 00000 | |

| 1" | 0.0036" | Acrylic | -40 | 325 | Not Rated | UL 510 | Silver | 000000000 | 00000 | 000000000 | 00000 | |

| 2" | 0.0036" | Acrylic | -40 | 325 | Not Rated | UL 510 | Silver | 0000000 | 00000 | 0000000 | 000000 | |

| 3" | 0.0036" | Acrylic | -40 | 325 | Not Rated | UL 510 | Silver | 000000000 | 00000 | 000000000 | 000000 | |

| 4" | 0.0036" | Acrylic | -40 | 325 | Not Rated | UL 510 | Silver | 000000000 | 00000 | 000000000 | 000000 | |

| 5" | 0.0036" | Acrylic | -40 | 325 | Not Rated | UL 510 | Silver | 000000000 | 00000 | 000000000 | 000000 | |

| 6" | 0.0036" | Acrylic | -40 | 325 | Not Rated | UL 510 | Silver | 000000000 | 00000 | 000000000 | 000000 | |

Changeable-Tip Picks

Handles

Handle Style | Overall Lg. | Max. Magnetic Pull, ozf | Grip Style | Handle Material | Each | |||

|---|---|---|---|---|---|---|---|---|

| Straight | 3 1/2" | 6 | Plain | Aluminum | 0000000 | 00000 | ||

Mesh Conductive Tape

Temp., ° F | 1" Wide | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., ft. | Overall Thk. | Material | Edge Material | Adhesive Type | Min. | Max. | Voltage Rating | Shielding Effectiveness @ Volume | Color | Each | ||

| 16 | 0.025" | Aluminum, Polyester Plastic | Tin-Coated Copper | Acrylic | -40 | 345 | Not Rated | 1 MHz @ 65 dB | Silver | 0000000 | 000000 | |

Low-Outgassing Aluminum Foil Conductive Tape

Heat-Transfer Mounting Tape

Wd. | Lg., ft. | Overall Thk. | Adhesive Location | Adhesive Type | Temp. Range, ° F | Voltage Rating | Thermal Conductivity, W/(m⋅°C) | Specs. Met | Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Foil | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3 | 0.009" | Both Sides | Acrylic | -20 to 255 | Not Rated | 1.4 | ASTM E595 | Gray | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 12 | 0.009" | Both Sides | Acrylic | -20 to 255 | Not Rated | 1.4 | ASTM E595 | Gray | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3 | 0.009" | Both Sides | Acrylic | -20 to 255 | Not Rated | 1.4 | ASTM E595 | Gray | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 12 | 0.009" | Both Sides | Acrylic | -20 to 255 | Not Rated | 1.4 | ASTM E595 | Gray | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 3 | 0.009" | Both Sides | Acrylic | -20 to 255 | Not Rated | 1.4 | ASTM E595 | Gray | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 12 | 0.009" | Both Sides | Acrylic | -20 to 255 | Not Rated | 1.4 | ASTM E595 | Gray | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||