Filter by

System of Measurement

Mount Type

Thread Size

Color

Bottom Plate Material

Weight Capacity

Maximum Pressure

Top Plate Material

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Movement

Clamping Fastener Thread Size

Specifications Met

Maximum Temperature

Number of Lines

Application

Threaded Rod Mounts

Mounting Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Material | For Thread Size | Wt. Cap., lb. | Lg. | Wd. | Ht. | Thk. | Rod Distance from Mounting Surface | Ctr.-to-Ctr. | No. of | Dia. | Mounting Fasteners Included | Threaded Rod Included | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wall Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | Steel | 7/16"-14, 7/16"-20 | 750 | 9" | 2" | 9" | 1/4" | 8" | 6 1/2" | 2 | 9/16" | No | No | 1 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | Steel | 7/16"-14, 7/16"-20 | 750 | 13" | 2" | 13" | 1/4" | 12" | 10 1/2" | 2 | 9/16" | No | No | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | Steel | 7/16"-14, 7/16"-20 | 750 | 19" | 2" | 19" | 1/4" | 18" | 16 1/2" | 2 | 9/16" | No | No | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | Zinc-Plated Steel | 7/16"-14, 7/16"-20 | 750 | 9" | 2" | 9" | 1/4" | 8" | 6 1/2" | 2 | 9/16" | No | No | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | Zinc-Plated Steel | 7/16"-14, 7/16"-20 | 750 | 13" | 2" | 13" | 1/4" | 12" | 10 1/2" | 2 | 9/16" | No | No | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | Zinc-Plated Steel | 7/16"-14, 7/16"-20 | 750 | 19" | 2" | 19" | 1/4" | 18" | 16 1/2" | 2 | 9/16" | No | No | 1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

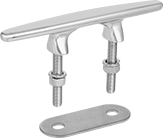

Wraparound Rope Cleats

Style L

For Max. Rope Dia. | Lg. | Overall Ht. | Mounting Fasteners Included | Thread Size | Stud Lg. | Mounting Stud Ctr.-to-Ctr. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Threaded-Stud Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 8" | 1 3/8" | Yes | 7/16"-14 | 2 1/2" | 2 13/16" | Backing Plate | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

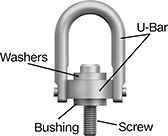

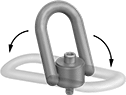

Hoist Ring Assortments—For Lifting

No. of Pieces | Thread Size | Movement | Includes | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Forged Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 124 | 1/4"-20 5/16"-18 3/8"-16 7/16"-14 1/2"-13 5/8"-11 3/4"-10 | 180° Pivot and 360° Swivel | Four 3/8" Dia. Shackles Four 1/2" Dia. Shackles Four 3/4" Dia. Shackles Four 1/4"-20 Bolts for 3/8" Dia. Shackle—600 lbs. Capacity and 1/2" Thread Lg. Four 5/16"-18 Bolts for 3/8" Dia. Shackle—800 lbs. Capacity and 1/2" Thread Lg. Four 3/8"-16 Bolts for 3/8" Dia. Shackle—1,000 lbs. Capacity and 1/2" Thread Lg. Four 7/16"-14 Bolts for 1/2" Dia. Shackle—2,000 lbs. Capacity and 1" Thread Lg. Four 1/2"-13 Bolts for 1/2" Dia. Shackle—2,500 lbs. Capacity and 1" Thread Lg. Four 5/8"-11 Bolts for 3/4" Dia. Shackle—4,000 lbs. Capacity and 1" Thread Lg. Four 3/4"-10 Bolts for 3/4" Dia. Shackle—5,000 lbs. Capacity and 1" Thread Lg. 28 Bushings 28 Retaining Rings 28 Washers | ASME B30.26 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

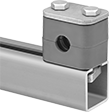

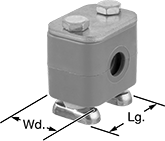

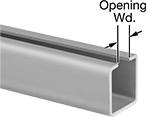

Rail-Mount Vibration-Damping Block Routing Clamps

ID | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inch | Metric, mm | For Pipe Size | Lg. | Wd. | Ht. | Max. Pressure, psi | For Rail Opening Wd. | Mounting Hardware Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Top Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 43 | 1 1/4 | 4 1/2" | 1 3/4" | 3 7/8" | 5,000 | 15/32" | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 44 | 1 1/4 | 4 1/2" | 1 3/4" | 3 7/8" | 5,000 | 15/32" | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 48 | 1 1/2 | 4 1/2" | 1 3/4" | 3 7/8" | 5,000 | 15/32" | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 51 | 1 1/2 | 4 1/2" | 1 3/4" | 3 7/8" | 5,000 | 15/32" | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 57 | — | 4 1/2" | 1 3/4" | 3 7/8" | 5,000 | 15/32" | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/8" | 60 | 2 | 4 1/2" | 1 3/4" | 3 7/8" | 5,000 | 15/32" | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 64 | 2 | 4 1/2" | 1 3/4" | 3 7/8" | 5,000 | 15/32" | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 70 | — | 4 1/2" | 1 3/4" | 3 7/8" | 5,000 | 15/32" | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

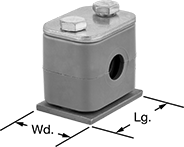

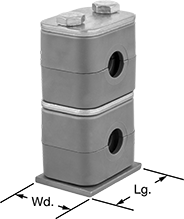

Weld-On Vibration-Damping Block Routing Clamps

ID | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inch | Metric, mm | For Pipe Size | Lg. | Wd. | Ht. | Max. Pressure, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Top and Bottom Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 43 | 1 1/4 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 44 | 1 1/4 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 48 | 1 1/2 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 51 | 1 1/2 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 57 | — | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/8" | 60 | 2 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 64 | 2 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 70 | — | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Top and Bottom Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 43 | 1 1/4 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 44 | 1 1/4 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 48 | 1 1/2 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 51 | 1 1/2 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 57 | — | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/8" | 60 | 2 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 64 | 2 | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 70 | — | 5 7/8" | 1 3/4" | 4 1/4" | 5,000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Top Plate and Zinc-Phosphate-Coated Steel Bottom Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 43 | 1 1/4 | 5 9/16" | 1 13/16" | 4 5/16" | 10,000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 44 | 1 1/4 | 5 9/16" | 1 13/16" | 4 5/16" | 10,000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 48 | 1 1/2 | 5 9/16" | 1 13/16" | 4 5/16" | 10,000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 51 | 1 1/2 | 5 9/16" | 1 13/16" | 4 5/16" | 10,000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/8" | 60 | 2 | 5 9/16" | 1 13/16" | 4 5/16" | 10,000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 64 | 2 | 5 9/16" | 1 13/16" | 4 5/16" | 10,000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 70 | — | 5 9/16" | 1 13/16" | 4 5/16" | 10,000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||