Filter by

Shape

Material

Inside Corner Shape

Leg Edge Shape

Outside Corner Shape

Hardness

Hardness Rating

Appearance

Heat Treatable

System of Measurement

Yield Strength

Elongation

Specifications Met

Fabrication

Surface Resistivity

Density

DFARS Specialty Metals

Export Control Classification Number (ECCN)

About Copper, Brass & Bronze

Compare over 30 copper, brass, and bronze alloys to find the right material for you—all with material certificates for traceability.

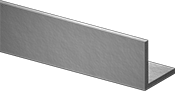

Easy-to-Machine Architectural 385 Brass 90° Angles

- Yield Strength: 16,000 psi

- Hardness: Rockwell B40 (Soft)

- Temper: M30

- Heat Treatable: No

- Specifications Met: ASTM B455

Often called architectural bronze, 385 brass is easy to machine and has excellent formability when heated. It is typically used for handrails, ornamental trim, and hardware, such as hinges and lock bodies.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Outside | Inside | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Ht. | Wd. | 2 ft. Lg. | 4 ft. Lg. | 6 ft. Lg. | |

1/16" Wall Thick. (-0.0006" to 0.0006" Tolerance) | |||||||||

| 3/4" | -0.008" to 0.008" | 3/4" | -0.008" to 0.008" | 11/16" | 11/16" | 0000000 | |||

1/8" Wall Thick. (-0.0013" to 0.0013" Tolerance) | |||||||||

| 1/2" | -0.005" to 0.005" | 1/2" | -0.005" to 0.005" | 3/8" | 3/8" | 0000000 | |||

| 3/4" | -0.008" to 0.008" | 3/4" | -0.008" to 0.008" | 5/8" | 5/8" | 0000000 | |||

| 1" | -0.01" to 0.01" | 3/4" | -0.008" to 0.008" | 7/8" | 5/8" | 0000000 | |||

| 1" | -0.01" to 0.01" | 1" | -0.01" to 0.01" | 7/8" | 7/8" | 0000000 | |||

| 1 1/4" | -0.013" to 0.013" | 1 1/4" | -0.013" to 0.013" | 1 1/8" | 1 1/8" | 0000000 | |||

| 1 1/2" | -0.015" to 0.015" | 1 1/2" | -0.015" to 0.015" | 1 3/8" | 1 3/8" | 0000000 | |||

| 2" | -0.02" to 0.02" | 2" | -0.02" to 0.02" | 1 7/8" | 1 7/8" | 0000000 | |||

3/16" Wall Thick. (-0.0019" to 0.0019" Tolerance) | |||||||||

| 1" | -0.01" to 0.01" | 1" | -0.01" to 0.01" | 13/16" | 13/16" | 0000000 | |||

| 1 1/4" | -0.013" to 0.013" | 1 1/4" | -0.013" to 0.013" | 1 1/16" | 1 1/16" | 0000000 | |||

| 1 1/2" | -0.015" to 0.015" | 1 1/2" | -0.015" to 0.015" | 1 5/16" | 1 5/16" | 0000000 | |||

| 2" | -0.02" to 0.02" | 2" | -0.02" to 0.02" | 1 13/16" | 1 13/16" | 0000000 | |||

1/4" Wall Thick. (-0.0025" to 0.0025" Tolerance) | |||||||||

| 1 1/2" | -0.015" to 0.015" | 1 1/2" | -0.015" to 0.015" | 1 1/4" | 1 1/4" | 0000000 | |||

| 2" | -0.02" to 0.02" | 2" | -0.02" to 0.02" | 1 3/4" | 1 3/4" | 0000000 | |||

| 3" | -0.03" to 0.03" | 3" | -0.03" to 0.03" | 2 3/4" | 2 3/4" | 0000000 | |||