How to Install Key-Locking Inserts

More

About Nuts, Materials, and Finishes

More

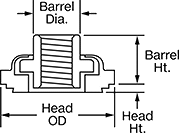

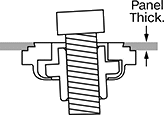

Stainless Steel Aligning Press-Fit Nuts for Sheet Metal

Install corrosion-resistant threads that align with off-center parts. These press-fit nuts have floating threads that account for misalignment, allowing you to insert screws at a slight angle as you fasten two parts together. Made of 18-8 stainless steel, they withstand mild chemicals and can be used in wet and outdoor environments. Use them to add permanent threads to sheet metal, like weld nuts but without the setup and mess. Also known as clinch-style captive nuts, press them into a drilled or punched hole with an arbor press or similar pressure tool. The pressure forms your sheet metal into the knurls of the nut, making the nut inseparable from the sheet. Installation requires access to both sides of the panel.

Head | Press-Fit Nuts | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Drill Bit Size | For Min. Panel Thick. | For Max. Panel Hardness | OD | Ht. | PEM® Part No. | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | |||||||||

| 4-40 | L | 0.038" | Brinell 125, Rockwell B70 | 0.36" | 0.13" | AC-440-1 | 5 | 000000000 | 00000 |

| 4-40 | L | 0.054" | Brinell 125, Rockwell B70 | 0.36" | 0.13" | AC-440-2 | 5 | 000000000 | 0000 |

| 6-32 | 21/64" | 0.038" | Brinell 125, Rockwell B70 | 0.39" | 0.13" | AC-632-1 | 5 | 000000000 | 0000 |

| 6-32 | 21/64" | 0.054" | Brinell 125, Rockwell B70 | 0.39" | 0.13" | AC-632-2 | 5 | 000000000 | 0000 |

| 8-32 | U | 0.054" | Brinell 125, Rockwell B70 | 0.44" | 0.13" | AC-832-2 | 5 | 000000000 | 0000 |

| 10-24 | 13/32" | 0.054" | Brinell 125, Rockwell B70 | 0.47" | 0.17" | AC-024-2 | 1 | 000000000 | 0000 |

| 10-32 | 13/32" | 0.038" | Brinell 125, Rockwell B70 | 0.47" | 0.17" | AC-032-1 | 1 | 000000000 | 0000 |

| 10-32 | 13/32" | 0.054" | Brinell 125, Rockwell B70 | 0.47" | 0.17" | AC-032-2 | 5 | 000000000 | 00000 |

| 1/4"-20 | 33/64" | 0.054" | Brinell 125, Rockwell B70 | 0.6" | 0.21" | AC-0420-2 | 1 | 000000000 | 0000 |

| 1/4"-28 | 33/64" | 0.054" | Brinell 125, Rockwell B70 | 0.6" | 0.21" | AC-0428-2 | 1 | 000000000 | 0000 |

Thread | Head | Press-Fit Nuts | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Drill Bit Size | For Min. Panel Thick., mm | For Max. Panel Hardness | OD, mm | Ht., mm | PEM® Part No. | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||||

| M3 | 0.5 | 7.4 mm | 0.97 | Brinell 125, Rockwell B70 | 9.14 | 3.31 | AC-M3-1 | 5 | 000000000 | 00000 |

| M3 | 0.5 | 7.4 mm | 1.38 | Brinell 125, Rockwell B70 | 9.14 | 3.31 | AC-M3-2 | 1 | 000000000 | 0000 |

| M4 | 0.7 | 9.4 mm | 0.97 | Brinell 125, Rockwell B70 | 11.18 | 3.31 | AC-M4-1 | 1 | 000000000 | 0000 |

| M4 | 0.7 | 9.4 mm | 1.38 | Brinell 125, Rockwell B70 | 11.18 | 3.31 | AC-M4-2 | 1 | 000000000 | 0000 |

| M5 | 0.8 | 10.4 mm | 1.38 | Brinell 125, Rockwell B70 | 11.94 | 4.32 | AC-M5-2 | 1 | 000000000 | 0000 |

| M6 | 1 | 13.1 mm | 1.38 | Brinell 125, Rockwell B70 | 15.24 | 5.34 | AC-M6-2 | 1 | 000000000 | 0000 |

Steel Aligning Press-Fit Nuts for Sheet Metal

Align off-center parts as you fasten them together—these steel press-fit nuts have floating threads, so you can install bolts at a slight angle. Zinc plating protects them from rust in wet environments. Use them to add permanent threads to sheet metal like weld nuts but without the setup and mess. Also known as clinch-style captive nuts, press them into a drilled or punched hole with an arbor press or similar pressure tool. The pressure forms your sheet metal into the knurls of the nut, making the nut inseparable from the sheet. Installation requires access to both sides of the panel.

Head | Press-Fit Nuts | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Drill Bit Size | For Min. Panel Thick. | For Max. Panel Hardness | OD | Ht. | PEM® Part No. | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | |||||||||

| 4-40 | L | 0.054" | Brinell 125, Rockwell B70 | 0.36" | 0.13" | AS-440-2 | 5 | 000000000 | 00000 |

| 6-32 | 21/64" | 0.054" | Brinell 125, Rockwell B70 | 0.39" | 0.13" | AS-632-2 | 5 | 000000000 | 0000 |

| 8-32 | U | 0.054" | Brinell 125, Rockwell B70 | 0.44" | 0.13" | AS-832-2 | 5 | 000000000 | 0000 |

| 10-32 | 13/32" | 0.054" | Brinell 125, Rockwell B70 | 0.47" | 0.17" | AS-032-2 | 5 | 000000000 | 0000 |

| 1/4"-20 | 33/64" | 0.054" | Brinell 125, Rockwell B70 | 0.6" | 0.21" | AS-0420-2 | 5 | 000000000 | 00000 |

Thread | Head | Press-Fit Nuts | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Drill Bit Size | For Min. Panel Thick., mm | For Max. Panel Hardness | OD, mm | Ht., mm | PEM® Part No. | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | ||||||||||

| M3 | 0.5 | 7.4 mm | 1.38 | Brinell 125, Rockwell B70 | 9.14 | 3.31 | AS-M3-2 | 5 | 000000000 | 00000 |

| M4 | 0.7 | 9.4 mm | 1.38 | Brinell 125, Rockwell B70 | 11.18 | 3.31 | AS-M4-2 | 5 | 000000000 | 0000 |

| M5 | 0.8 | 10.3 mm | 1.38 | Brinell 125, Rockwell B70 | 11.94 | 4.32 | AS-M5-2 | 5 | 000000000 | 00000 |

| M6 | 1 | 13.1 mm | 1.38 | Brinell 125, Rockwell B70 | 15.24 | 5.34 | AS-M6-2 | 1 | 000000000 | 0000 |

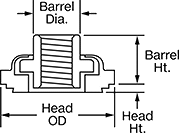

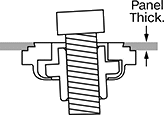

Stainless Steel Screw-Locking Aligning Press-Fit Nuts for Sheet Metal

Irregularly shaped threads in these press-fit nuts form a tight grip, preventing screws from backing out in vibration-heavy environments. Use these nuts to install corrosion-resistant threads that align with off-center parts. They have floating threads that account for misalignment, allowing you to insert screws at a slight angle as you fasten two parts together. With a long, extended barrel that’s threaded from end-to-end, these nuts have excellent thread engagement. They’re made of 18-8 stainless steel, so they stand up to mild chemicals and wet and outdoor environments.

Use press-fit nuts to add permanent threads to sheet metal, like weld nuts but without the setup and mess. Also known as clinch-style captive nuts, press them into a drilled or punched hole with an arbor press or similar pressure tool. The pressure forms your sheet metal into the knurls of the nut, making the nut inseparable from the sheet. Installation requires access to both sides of the panel.

Nuts that meet NASM25027 adhere to National Aerospace Standards for tight tolerances and locking torque.

Head | Barrel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Drill Bit Size | For Min. Panel Thick. | For Max. Panel Hardness | OD | Ht. | Dia. | Ht. | PEM® Part No. | Specifications Met | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||||||

| 4-40 | L | 0.038" | Brinell 125, Rockwell B70 | 0.36" | 0.038" | 9/64" | 3/16" | LAC-440-1MD | NASM25027 | 5 | 000000000 | 00000 |

| 4-40 | L | 0.054" | Brinell 125, Rockwell B70 | 0.36" | 0.054" | 9/64" | 3/16" | LAC-440-2MD | NASM25027 | 5 | 000000000 | 0000 |

| 6-32 | 21/64" | 0.038" | Brinell 125, Rockwell B70 | 0.39" | 0.038" | 3/16" | 13/64" | LAC-632-1MD | NASM25027 | 5 | 000000000 | 00000 |

| 6-32 | 21/64" | 0.054" | Brinell 125, Rockwell B70 | 0.39" | 0.054" | 3/16" | 13/64" | LAC-632-2MD | NASM25027 | 5 | 000000000 | 00000 |

| 8-32 | U | 0.038" | Brinell 125, Rockwell B70 | 0.44" | 0.038" | 15/64" | 13/64" | LAC-832-1MD | NASM25027 | 5 | 000000000 | 00000 |

| 8-32 | U | 0.054" | Brinell 125, Rockwell B70 | 0.44" | 0.054" | 15/64" | 13/64" | LAC-832-2MD | NASM25027 | 5 | 000000000 | 00000 |

| 10-24 | 13/32" | 0.054" | Brinell 125, Rockwell B70 | 0.47" | 0.054" | 7/32" | 17/64" | LAC-024-2MD | NASM25027 | 5 | 000000000 | 00000 |

| 10-32 | 13/32" | 0.038" | Brinell 125, Rockwell B70 | 0.47" | 0.038" | 7/32" | 17/64" | LAC-032-1MD | NASM25027 | 5 | 000000000 | 00000 |

| 10-32 | 13/32" | 0.054" | Brinell 125, Rockwell B70 | 0.47" | 0.054" | 17/64" | 17/64" | LAC-032-2MD | NASM25027 | 5 | 000000000 | 00000 |

| 1/4"-20 | 33/64" | 0.054" | Brinell 125, Rockwell B70 | 0.6" | 0.054" | 11/32" | 5/16" | LAC-0420-2MD | NASM25027 | 1 | 000000000 | 0000 |

Thread | Head | Barrel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Drill Bit Size | For Min. Panel Thick., mm | For Max. Panel Hardness | OD, mm | Ht., mm | Dia., mm | Ht., mm | PEM® Part No. | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||||||

| M3 | 0.5 | 7.4 mm | 0.97 | Brinell 125, Rockwell B70 | 9.14 | 0.97 | 4.2 | 4.8 | LAC-M3-1MD | 5 | 000000000 | 000000 |

| M3 | 0.5 | 7.4 mm | 1.38 | Brinell 125, Rockwell B70 | 9.14 | 1.38 | 3.6 | 4.8 | LAC-M3-2MD | 5 | 000000000 | 00000 |

| M4 | 0.7 | 9.4 mm | 0.97 | Brinell 125, Rockwell B70 | 11.18 | 0.97 | 4.8 | 5.3 | LAC-M4-1MD | 5 | 000000000 | 00000 |

| M4 | 0.7 | 9.4 mm | 1.38 | Brinell 125, Rockwell B70 | 11.18 | 1.38 | 4.8 | 5.3 | LAC-M4-2MD | 5 | 000000000 | 00000 |

| M5 | 0.8 | 10.3 mm | 0.97 | Brinell 125, Rockwell B70 | 11.94 | 0.97 | 6 | 6.9 | LAC-M5-1MD | 5 | 000000000 | 00000 |

| M5 | 0.8 | 10.3 mm | 1.38 | Brinell 125, Rockwell B70 | 11.94 | 1.38 | 6 | 6.9 | LAC-M5-2MD | 5 | 000000000 | 00000 |

| M6 | 1 | 13.1 mm | 1.38 | Brinell 125, Rockwell B70 | 15.24 | 1.38 | 7.2 | 7.9 | LAC-M6-2MD | 1 | 000000000 | 0000 |

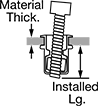

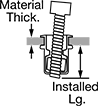

Aligning Rivet Nuts

Threads float inside the nut so you can install a screw at a slight angle to align with off-center parts. They’re also known as Riv-Float nuts. A ribbed body makes them resistant to spinning and twisting. They're zinc plated for mild corrosion resistance. Install in a drilled hole with a wrench-driven tool (required, sold separately). Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

Rivet Nuts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Body | Flange | Wrench-Driven Rivet Nut Tools | |||||||||||

| Thread Size | Drill Bit Size | For Material Thick. | Type | Dia. | Lg. | Installed Lg. | Dia. | Thick. | Pkg. Qty. | Pkg. | Each | ||

Zinc-Plated Steel | |||||||||||||

| 8-32 | 25/64" | 0.027" to 0.130" | Ribbed | 0.39" | 0.690" | 0.522" | 0.500" | 0.030" | 10 | 000000000 | 00000 | 000000000 | 000000 |

| 8-32 | 7/16" | 0.020" to 0.100" | Ribbed | 0.43" | 0.498" | 0.315" | 0.555" | 0.033" | 5 | 000000000 | 0000 | 000000 | 00 |

| 10-24 | 7/16" | 0.020" to 0.100" | Ribbed | 0.43" | 0.498" | 0.315" | 0.555" | 0.033" | 5 | 000000000 | 0000 | 000000 | 00 |

| 10-32 | 25/64" | 0.027" to 0.150" | Ribbed | 0.39" | 0.690" | 0.522" | 0.500" | 0.030" | 10 | 000000000 | 0000 | 000000000 | 00000 |

| 10-32 | 7/16" | 0.020" to 0.100" | Ribbed | 0.43" | 0.498" | 0.315" | 0.555" | 0.033" | 5 | 000000000 | 0000 | 000000 | 00 |

| 1/4"-20 | 17/32" | 0.027" to 0.150" | Ribbed | 0.53" | 0.784" | 0.630" | 0.685" | 0.035" | 10 | 000000000 | 00000 | 000000000 | 00000 |

Rivet Nuts | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread | Body | Flange | Wrench-Driven Rivet Nut Tools | |||||||||||

| Size | Pitch, mm | Drill Bit Size | For Material Thick., mm | Type | Dia., mm | Lg., mm | Installed Lg., mm | Dia., mm | Thick., mm | Pkg. Qty. | Pkg. | Each | ||

Zinc-Plated Steel | ||||||||||||||

| M4 | 0.7 | 10 mm | 0.7 to 3.3 | Ribbed | 9.9 | 17.5 | 13.3 | 12.7 | 0.8 | 10 | 000000000 | 00000 | 000000000 | 000000 |

| M4 | 0.7 | 11 mm | 0.5 to 2.5 | Ribbed | 11 | 12.6 | 8 | 14.1 | 0.9 | 5 | 000000000 | 0000 | 000000 | 00 |

| M5 | 0.8 | 10 mm | 0.7 to 3.8 | Ribbed | 9.9 | 17.5 | 13.3 | 12.7 | 0.8 | 10 | 000000000 | 0000 | 000000000 | 00000 |

| M5 | 0.8 | 11 mm | 0.5 to 2.5 | Ribbed | 11 | 12.6 | 8 | 14.1 | 0.9 | 5 | 000000000 | 0000 | 000000 | 00 |

| M6 | 1 | 13.5 mm | 0.7 to 3.8 | Ribbed | 13.5 | 19.9 | 16 | 17.4 | 0.9 | 10 | 000000000 | 00000 | 000000000 | 00000 |

Aligning Weld Nuts

Threads float inside the retainer so you can install a bolt at a slight angle to align with off-center parts. Weld these nuts to metal surfaces for a strong, permanent hold. They stand up to high torque and pulling force better than rivet nuts.

For the strongest threads, choose steel nuts. Nuts with a steel retainer should be welded to uncoated steel surfaces. Zinc-plated steel nuts resist corrosion in wet environments. Nuts with an aluminum retainer should be welded to aluminum surfaces.

For the most corrosion resistance, choose stainless steel nuts. They have a stainless steel retainer, so they should be welded to stainless steel surfaces.

Base | |||||||

|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Wd. | Thick. | Ht. | Pkg. Qty. | Pkg. | |

Steel Nut with C1008/C1010 Steel Retainer | |||||||

| 6-32 | 1 1/2" | 1/2" | 3/64" | 29/64" | 1 | 000000000 | 00000 |

| 8-32 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 10-24 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 10-32 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 7/16" | 10 | 000000000 | 00000 |

| 1/4"-28 | 1 3/4" | 9/16" | 1/16" | 7/16" | 10 | 000000000 | 00000 |

| 5/16"-18 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 5/16"-24 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 3/8"-16 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 3/8"-24 | 2" | 25/32" | 1/16" | 33/64" | 5 | 000000000 | 00000 |

| 7/16"-14 | 2 1/4" | 15/16" | 1/16" | 51/64" | 5 | 000000000 | 00000 |

| 1/2"-13 | 2 1/4" | 15/16" | 1/16" | 51/64" | 5 | 000000000 | 00000 |

Zinc-Plated Steel Nut with 5052 Aluminum Retainer | |||||||

| 10-32 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 7/16" | 10 | 000000000 | 00000 |

| 5/16"-18 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 3/8"-16 | 2" | 25/32" | 1/16" | 33/64" | 5 | 000000000 | 00000 |

Zinc-Plated Steel Nut with C1008/C1010 Steel Retainer | |||||||

| 10-24 | 1 1/2" | 1/2" | 3/64" | 11/32" | 5 | 000000000 | 0000 |

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 7/16" | 5 | 000000000 | 0000 |

| 5/16"-18 | 2" | 25/32" | 1/16" | 33/64" | 5 | 000000000 | 00000 |

Stainless Steel Nut with Stainless Steel Retainer | |||||||

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 11/32" | 1 | 000000000 | 00000 |

Metric Aligning Weld Nuts

Threads float inside the retainer so you can install a bolt at a slight angle to align with off-center parts. Weld these nuts to metal surfaces for a strong permanent hold. They stand up to high torque and pulling force better than rivet nuts.

Weld steel nuts with a steel retainer to uncoated steel surfaces.

Weld zinc-plated steel nuts with an aluminum retainer to aluminum surfaces. They resist corrosion in wet environments.

Thread | Base | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Lg., mm | Wd., mm | Thick., mm | Ht., mm | Pkg. Qty. | Pkg. | |

Steel Nut with C1008/C1010 Steel Retainer | ||||||||

| M5 | 0.8 | 38.1 | 12.7 | 1.06 | 8.6 | 5 | 000000000 | 000000 |

| M6 | 1 | 38.1 | 12.7 | 1.06 | 8.6 | 10 | 000000000 | 00000 |

| M8 | 1.25 | 50.8 | 19.8 | 1.27 | 13.7 | 5 | 000000000 | 00000 |

| M10 | 1.5 | 50.8 | 19.8 | 1.27 | 13 | 5 | 000000000 | 00000 |

| M12 | 1.75 | 58.7 | 23.8 | 1.27 | 20.2 | 5 | 000000000 | 00000 |

Zinc-Plated Steel Nut with 5052 Aluminum Retainer | ||||||||

| M10 | 1.5 | 50.8 | 19.8 | 1.27 | 13 | 5 | 000000000 | 00000 |

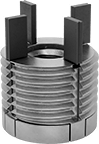

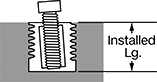

Aligning Key-Locking Inserts

Install threads that align with off-center parts. These inserts have floating threads that account for misalignment, allowing you to insert screws at a slight angle as you fasten two parts together. With keys that drive into the surrounding material, they have a more secure hold than thread-locking inserts. Use them to repair or add new threads in soft metal, such as aluminum. They’re a close alternative to Keensert® inserts. Install them using a drill bit, a standard tap, an installation tool, and a hammer.

18-8 stainless steel inserts resist corrosion from mild chemicals and water. Because they have a thin wall, they’re often used in small holes or near the edge of a workpiece.

Alloy steel inserts are among the strongest we offer. The cadmium plating protects them from corroding in wet environments. They may be mildly magnetic. These inserts have a thick wall that’s best suited for large holes. They’re often used to replace damaged threads that have been drilled out.

Inserts | Installation Tools | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | Each | Each | ||

18-8 Stainless Steel with Thin Wall | |||||||||

| 2-56 | 1/4"-28 | 3/16" | No. 1 | 0.228" | 2 | 000000000 | 000000 | 00000000 | 0000000 |

| 4-40 | 5/16"-24 | 5/16" | I | 0.272" | 2 | 000000000 | 00000 | 00000000 | 000000 |

| 6-32 | 3/8"-24 | 3/8" | Q | 0.332" | 2 | 000000000 | 00000 | 00000000 | 000000 |

| 8-32 | 3/8"-24 | 3/8" | Q | 0.332" | 2 | 000000000 | 00000 | 00000000 | 000000 |

Cadmium-Plated Alloy Steel with Thick Wall | |||||||||

| 10-24 | 7/16"-20 | 3/8" | 13/32" | 0.406" | 2 | 000000000 | 00000 | 00000000 | 000000 |

| 10-32 | 7/16"-20 | 3/8" | 13/32" | 0.406" | 2 | 000000000 | 00000 | 00000000 | 000000 |

| 1/4"-20 | 1/2"-20 | 3/8" | 15/32" | 0.468" | 2 | 000000000 | 00000 | 00000000 | 000000 |

| 1/4"-28 | 1/2"-20 | 3/8" | 15/32" | 0.468" | 2 | 000000000 | 00000 | 00000000 | 000000 |

| 5/16"-18 | 5/8"-18 | 1/2" | 37/64" | 0.578" | 4 | 000000000 | 00000 | 00000000 | 000000 |

| 5/16"-24 | 5/8"-18 | 1/2" | 37/64" | 0.578" | 4 | 000000000 | 00000 | 00000000 | 000000 |

| 3/8"-16 | 3/4"-16 | 5/8" | 45/64" | 0.703" | 4 | 000000000 | 00000 | 00000000 | 000000 |

| 3/8"-24 | 3/4"-16 | 5/8" | 45/64" | 0.703" | 4 | 000000000 | 00000 | 00000000 | 000000 |

| 7/16"-14 | 7/8"-14 | 11/16" | 53/64" | 0.828" | 4 | 000000000 | 00000 | 00000000 | 000000 |

| 7/16"-20 | 7/8"-14 | 11/16" | 53/64" | 0.828" | 4 | 000000000 | 00000 | 00000000 | 000000 |

| 1/2"-13 | 1"-12 | 3/4" | 15/16" | 0.937" | 4 | 000000000 | 00000 | 00000000 | 000000 |

| 1/2"-20 | 1"-12 | 3/4" | 15/16" | 0.937" | 4 | 000000000 | 00000 | 00000000 | 000000 |