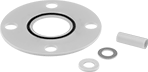

Water-Resistant Aramid/SBR Pipe Gaskets with Bolt Holes for Uneven Surfaces

Often called controlled swell gaskets, these gaskets absorb water near the inside of the flange and swell to fill gaps. Use them on uneven surfaces, such as grooved, corroded, or pitted flanges as well as flanges that you can’t tighten too much or may have loosened. The controlled swell of these gaskets helps reduce the stress it puts on your flange’s bolts and decreases leaks. Made of a blend of Aramid and SBR, these flanges resist breaking down from water. They’re safe to use in drinking water systems because they meet strict NSF/ANSI 61 standards. All are for ANSI Class 150 flanges, so they are compatible with low-pressure pipe flanges.

1/16" Thick. | 1/8" Thick. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | ID | OD | No. of Bolt Holes | Max. Pressure, psi | Temp. Range, °F | Color | Each | Each | ||

For ANSI Class 150 | ||||||||||

| 1 | 1 5/16" | 4 1/4" | 4 | 500 | -100° to 400° | Blue | 0000000 | 00000 | 0000000 | 00000 |

| 1 1/2 | 1 29/32" | 5" | 4 | 500 | -100° to 400° | Blue | 0000000 | 0000 | 0000000 | 0000 |

| 2 | 2 3/8" | 6" | 4 | 500 | -100° to 400° | Blue | 0000000 | 0000 | 0000000 | 00000 |

| 3 | 3 1/2" | 7 1/2" | 4 | 500 | -100° to 400° | Blue | 0000000 | 0000 | 0000000 | 00000 |

| 4 | 4 1/2" | 9" | 8 | 500 | -100° to 400° | Blue | 0000000 | 00000 | 0000000 | 00000 |

| 6 | 6 5/8" | 11" | 8 | 500 | -100° to 400° | Blue | 0000000 | 00000 | 0000000 | 00000 |

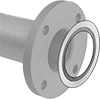

Water- and Steam-Resistant EPDM Pipe

Gaskets with Bolt Holes for Dissimilar Metals

Furnished with plastic sleeves and washers to provide a layer of protection against dielectric corrosion, which occurs when different metals are joined. These gaskets are commonly called full-face gaskets; they cover the entire face of flat-surface pipe flanges and align with the bolt holes. They’re made of EPDM rubber and resist water, steam, and salt water. They are compatible with low-pressure pipe flanges; all gasket specifications are sized to meet ANSI standards. Each gasket comes with one full-length sleeve for each bolt hole, plus two phenolic and two zinc-plated metal washers for each bolt hole. Bolts are not included.

| For Pipe Size | ID | OD | Thick. | No. of Bolt Holes | Max. Pressure, psi | Max. Temperature, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

For ANSI Class 150 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 5/16" | 4 1/4" | 1/8" | 4 | 285 | 250° | Durometer 70A | Hard | Off-White | NSF/ANSI 61 | 0000000 | 000000 |

| 1 1/2 | 1 29/32" | 5" | 1/8" | 4 | 285 | 250° | Durometer 70A | Hard | Off-White | NSF/ANSI 61 | 0000000 | 00000 |

| 2 | 2 3/8" | 6" | 1/8" | 4 | 285 | 250° | Durometer 70A | Hard | Off-White | NSF/ANSI 61 | 0000000 | 00000 |

| 2 1/2 | 2 7/8" | 7" | 1/8" | 4 | 285 | 250° | Durometer 70A | Hard | Off-White | NSF/ANSI 61 | 0000000 | 00000 |

| 3 | 3 1/2" | 7 1/2" | 1/8" | 4 | 285 | 250° | Durometer 70A | Hard | Off-White | NSF/ANSI 61 | 0000000 | 00000 |

| 4 | 4 1/2" | 9" | 1/8" | 8 | 285 | 250° | Durometer 70A | Hard | Off-White | NSF/ANSI 61 | 0000000 | 00000 |

| 6 | 6 5/8" | 11" | 1/8" | 8 | 285 | 250° | Durometer 70A | Hard | Off-White | NSF/ANSI 61 | 0000000 | 000000 |

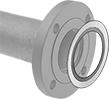

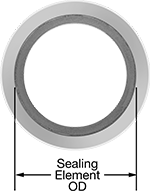

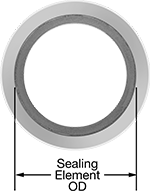

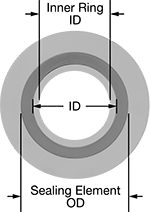

High-Temperature Metallic Pipe Gaskets

a Flat-Surface

Pipe Flange

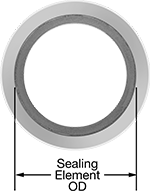

Also known as spiral-wound gaskets, these have a 1/8” thick carbon steel outer ring and a 304 stainless steel sealing element with a graphite-based filler. The metal construction provides structural strength. These gaskets can be used with both flat-surface and raised-surfaces pipe flanges; they fit the surface inside the bolt holes and do not interfere with the bolt connection.

Gaskets for ANSI class flanges are sized so all gasket specifications meet ANSI standards. Gaskets for ANSI Class 150 flanges are compatible with low-pressure pipe flanges. Gaskets for ANSI Class 300 flanges are compatible with medium-pressure pipe flanges. Gaskets for ANSI Class 600 flanges are compatible with high-pressure pipe flanges. Gaskets for ANSI Class 1500 flanges are compatible with extreme-pressure pipe flanges.

Gaskets with an inner ring prevent flange erosion.

Sealing Element | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | ID | OD | Thick. | OD | Wd. | Max. Pressure | Temperature Range, °F | Material | Sealing Element Material | Sealing Element Filler Material | Specifications Met | Each | |

| 1/2 | 3/4" | 1 7/8" | 1/8" | 1 1/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 3/4 | 1" | 2 1/4" | 1/8" | 1 9/16" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 1 | 1 1/4" | 2 5/8" | 1/8" | 1 7/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 1 1/4 | 1 7/8" | 3" | 1/8" | 2 3/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 3 3/8" | 1/8" | 2 3/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 2 | 2 3/4" | 4 1/8" | 1/8" | 3 3/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 2 1/2 | 3 1/4" | 4 7/8" | 1/8" | 3 7/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 3 | 4" | 5 3/8" | 1/8" | 4 3/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 4 | 5" | 6 7/8" | 1/8" | 5 7/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 5 | 6 1/8" | 7 3/4" | 1/8" | 7" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 6 | 7 3/16" | 8 3/4" | 1/8" | 8 1/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 8 | 9 3/16" | 11" | 1/8" | 10 3/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 10 | 11 5/16" | 13 3/8" | 1/8" | 12 1/2" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

Sealing Element | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | ID | OD | Thick. | OD | Wd. | Max. Pressure | Temperature Range, °F | Material | Sealing Element Material | Sealing Element Filler Material | Specifications Met | Each | |

| 1/2 | 3/4" | 2 1/8" | 1/8" | 1 1/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 3/4 | 1" | 2 5/8" | 1/8" | 1 9/16" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 1 | 1 1/4" | 2 7/8" | 1/8" | 1 7/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 1 1/4 | 1 7/8" | 3 1/4" | 1/8" | 2 3/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 3 3/4" | 1/8" | 2 3/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 2 | 2 3/4" | 4 3/8" | 1/8" | 3 3/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 2 1/2 | 3 1/4" | 5 1/8" | 1/8" | 3 7/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 3 | 4" | 5 7/8" | 1/8" | 4 3/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 4 | 5" | 7 1/8" | 1/8" | 5 7/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 5 | 6 1/8" | 8 1/2" | 1/8" | 7" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 6 | 7 3/16" | 9 7/8" | 1/8" | 8 1/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

Sealing Element | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | ID | OD | Thick. | OD | Wd. | Max. Pressure | Temperature Range, °F | Material | Sealing Element Material | Sealing Element Filler Material | Specifications Met | Each | |

| 1/2 | 3/4" | 2 1/8" | 1/8" | 1 1/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 3/4 | 1" | 2 5/8" | 1/8" | 1 9/16" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 1 | 1 1/4" | 2 7/8" | 1/8" | 1 7/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 1 1/4 | 1 7/8" | 3 1/4" | 1/8" | 2 3/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 3 3/4" | 1/8" | 2 3/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 2 | 2 3/4" | 4 3/8" | 1/8" | 3 3/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 2 1/2 | 3 1/4" | 5 1/8" | 1/8" | 3 7/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 0000 |

| 3 | 4" | 5 7/8" | 1/8" | 4 3/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 3 1/2 | 4 1/8" | 6 3/8" | 1/8" | 5 1/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 4 | 4 3/4" | 7 5/8" | 1/8" | 5 7/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 5 | 5 13/16" | 9 1/2" | 1/8" | 7" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 6 | 6 7/8" | 10 1/2" | 1/8" | 8 1/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 8 | 8 7/8" | 12 5/8" | 1/8" | 10 3/8" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 10 | 10 13/16" | 15 3/4" | 1/8" | 12 1/2" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

| 12 | 12 7/8" | 18" | 1/8" | 14 3/4" | 0.175" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | ASME B16.20 | 000000000 | 00000 |

Sealing Element | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | ID | OD | Thick. | OD | Wd. | Inner Ring ID | Max. Pressure | Temperature Range, °F | Material | Sealing Element Material | Sealing Element Filler Material | Inner Ring Material | Specifications Met | Each | |

| 1/2 | 3/4" | 2 1/2" | 1/8" | 1 1/4" | 0.175" | 0.56" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 000000 |

| 3/4 | 1" | 2 3/4" | 1/8" | 1 9/16" | 0.175" | 0.81" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 00000 |

| 1 | 1 1/4" | 3 1/8" | 1/8" | 1 7/8" | 0.175" | 1.06" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 00000 |

| 1 1/4 | 1 9/16" | 3 1/2" | 1/8" | 2 3/8" | 0.175" | 1.31" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 00000 |

| 1 1/2 | 1 7/8" | 3 7/8" | 1/8" | 2 3/4" | 0.175" | 1.63" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 00000 |

| 2 | 2 5/16" | 5 5/8" | 1/8" | 3 3/8" | 0.175" | 2.06" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 00000 |

| 2 1/2 | 2 3/4" | 6 1/2" | 1/8" | 3 7/8" | 0.175" | 2.50" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 00000 |

| 3 | 3 5/8" | 6 7/8" | 1/8" | 4 3/4" | 0.175" | 3.10" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 00000 |

| 4 | 4 5/8" | 8 1/4" | 1/8" | 5 7/8" | 0.175" | 3.85" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 00000 |

| 5 | 5 5/8" | 10" | 1/8" | 7" | 0.175" | 4.90" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 00000 |

| 6 | 6 3/4" | 11 1/8" | 1/8" | 8 1/4" | 0.175" | 5.80" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 000000 |

| 8 | 8 1/2" | 13 7/8" | 1/8" | 10 1/8" | 0.175" | 7.75" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 000000 |

| 10 | 10 1/2" | 17 1/8" | 1/8" | 12 1/4" | 0.175" | 9.69" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 000000 |

| 12 | 12 3/4" | 20 1/2" | 1/8" | 14 1/2" | 0.175" | 11.50" | Not Rated | -50° to 840° | Carbon Steel | 304 Stainless Steel | Graphite | 304 Stainless Steel | ASME B16.20 | 000000000 | 000000 |

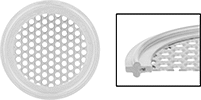

Ultra-Chemical-Resistant PTFE Gaskets with

Perforations for Quick-Clamp Tube Fittings

These chemical-resistant gaskets have a perforated plate that filters, separates, and strains liquids or dry materials in your line. Made of 316 stainless steel, the plate won’t corrode from frequent washdowns with harsh cleaners. Gaskets are made of PTFE for excellent resistance to detergents, hydraulic fluid, and salts, and good resistance to most acids and alkalis. They create tight seals in quick-clamp sanitary tube fittings. These gaskets are 3-A certified for sanitary design and are FDA compliant for direct contact with food. They meet ASME BPE purity and safety standards, and are rated USP Class VI as plastic that won’t leach into biological samples.

| For Tube OD | ID | OD | Thickness | Temperature Range, °F | Color | Specifications Met | Each | |

Straight Holes | ||||||||

|---|---|---|---|---|---|---|---|---|

0.033" Hole Diameter | ||||||||

| 1 1/2" | 1.400" | 1.980" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 0000000 |

| 2" | 1.900" | 2.520" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 2 1/2" | 2.400" | 3.050" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 3" | 2.900" | 3.580" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 4" | 3.870" | 4.680" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

Staggered Holes | ||||||||

1/16" Hole Diameter | ||||||||

| 1 1/2" | 1.400" | 1.980" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 2" | 1.900" | 2.520" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 2 1/2" | 2.400" | 3.050" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 3" | 2.900" | 3.580" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 4" | 3.870" | 4.680" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

1/8" Hole Diameter | ||||||||

| 1 1/2" | 1.400" | 1.980" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 2" | 1.900" | 2.520" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 2 1/2" | 2.400" | 3.050" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 3" | 2.900" | 3.580" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 4" | 3.870" | 4.680" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

1/4" Hole Diameter | ||||||||

| 1 1/2" | 1.400" | 1.980" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 2" | 1.900" | 2.520" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 2 1/2" | 2.400" | 3.050" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 3" | 2.900" | 3.580" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 4" | 3.870" | 4.680" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

Water- and Steam-Resistant EPDM Gaskets

with Perforations for Quick-Clamp Tube Fittings

These gaskets have a perforated plate to filter, separate, and strain liquids or dry materials in your line. Made of 316 stainless steel, the plate won’t corrode from frequent washdowns with harsh cleaners. Neither will the rest of these gaskets, which are made of EPDM rubber that resists water, steam, and UV light. In addition to filtering, they ensure a tight seal in quick-clamp stainless steel sanitary tube fittings. Gaskets are FDA compliant for direct contact with food and 3-A certified as meeting sanitary design standards. They meet ASME BPE purity and safety standards for bioprocessing equipment, and are rated USP Class VI as made from plastic that won’t contaminate biological samples.

| For Tube OD | ID | OD | Thickness | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

Straight Holes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

0.033" Hole Diameter | ||||||||||

| 1" | 0.900" | 1.980" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 1 1/2" | 1.400" | 1.980" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 2" | 1.900" | 2.520" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 2 1/2" | 2.400" | 3.050" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 3" | 2.900" | 3.580" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 4" | 3.870" | 4.680" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

Staggered Holes | ||||||||||

1/16" Hole Diameter | ||||||||||

| 1 1/2" | 1.400" | 1.980" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 2" | 1.900" | 2.520" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 2 1/2" | 2.400" | 3.050" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 3" | 2.900" | 3.580" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 4" | 3.870" | 4.680" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

1/8" Hole Diameter | ||||||||||

| 1" | 0.900" | 1.980" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 1 1/2" | 1.400" | 1.980" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 2" | 1.900" | 2.520" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 2 1/2" | 2.400" | 3.050" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 3" | 2.900" | 3.580" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 4" | 3.870" | 4.680" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

1/4" Hole Diameter | ||||||||||

| 1" | 0.900" | 1.980" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 1 1/2" | 1.400" | 1.980" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 2" | 1.900" | 2.520" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 2 1/2" | 2.400" | 3.050" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 3" | 2.900" | 3.580" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 4" | 3.870" | 4.680" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

High-Temperature Silicone Gaskets with

Perforations for Quick-Clamp Tube Fittings

Use these perforated gaskets to filter liquids and dry materials, as well as create a tight seal in quick-clamp stainless steel sanitary tube fittings. Made of silicone, they handle temperatures up to 450° F, so they’re good for heated ingredients and clean-in-place (CIP) processes. However, oils will degrade them. Their perforated plate is 316 stainless steel to withstand washdowns with harsh cleaners and sanitizers. All of these gaskets are 3-A certified to meet sanitary design standards and FDA compliant for direct contact with food. USP Class VI, they’ve been tested to the highest standards to reduce the risk of leaching into biological samples. They also meet ASME BPE, which is a design standard for bioprocessing equipment that helps ensure purity and safety.

| For Tube OD | ID | OD | Thickness | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

Staggered Holes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

1/16" Hole Diameter | ||||||||||

| 1 1/2" | 1.400" | 1.980" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 2" | 1.900" | 2.520" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 3" | 2.900" | 3.580" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

1/8" Hole Diameter | ||||||||||

| 1 1/2" | 1.400" | 1.980" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 2" | 1.900" | 2.520" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 3" | 2.900" | 3.580" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

1/4" Hole Diameter | ||||||||||

| 1 1/2" | 1.400" | 1.980" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 2" | 1.900" | 2.520" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 00000 |

| 3" | 2.900" | 3.580" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

| 4" | 3.870" | 4.680" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |