Filter by

Body Material

For Use With

Fitting Connection

Maximum Pressure @ Temperature

Mounting Position

Check Valve Type

DFARS Specialty Metals

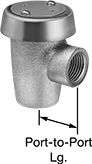

Vacuum Breakers

90° Elbow

Brass Body | Chrome-Plated Bronze Body | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | Outlet Pipe SIze | Max. Pressure @ Temp. | Temp. Range, ° F | Port-to-Port Lg. | Seal Material | For Use With | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1/4 | 125 psi @ 70° F | 35 to 180 | 1" | Silicone Rubber | Water | ——— | 0 | 9903K31 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 3/8 | 125 psi @ 70° F | 35 to 180 | 1" | Silicone Rubber | Water | ——— | 0 | 9903K33 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1/2 | 125 psi @ 70° F | 35 to 180 | 1 1/4" | Silicone Rubber | Water | ——— | 0 | 9903K35 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1/2 | 125 psi @ 70° F | 35 to 180 | 1 5/16" | Silicone Rubber | Water | 47685K12 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 3/4 | 125 psi @ 70° F | 35 to 180 | 1 1/2" | Silicone Rubber | Water | 47685K34 | 00000 | 9903K37 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1 | 125 psi @ 70° F | 35 to 180 | 1 5/8" | Silicone Rubber | Water | 47685K36 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4 | 1 1/4 | 125 psi @ 70° F | 35 to 180 | 2" | Silicone Rubber | Water | 47685K44 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 1 1/2 | 125 psi @ 70° F | 35 to 180 | 2 1/4" | Silicone Rubber | Water | 47685K46 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 2 | 125 psi @ 70° F | 35 to 180 | 2 3/4" | Silicone Rubber | Water | 47685K48 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight

Brass Body | 303 Stainless Steel Body | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | Outlet Pipe SIze | Max. Pressure @ Temp. | Temp. Range, ° F | End-to-End Lg. | Seal Material | For Use With | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 3/8 | 300 psi @ 70° F | -20 to 365 | 1 3/4" | EPM Rubber | Air, Argon, Helium, Krypton, Neon, Steam, Water, Xenon | 4817K14 | 0000000 | 4817K24 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1/2 | 300 psi @ 70° F | -20 to 365 | 2 1/8" | EPM Rubber | Air, Argon, Helium, Krypton, Neon, Steam, Water, Xenon | 4817K15 | 000000 | 4817K25 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3/4 | 300 psi @ 70° F | -20 to 365 | 2 3/8" | EPM Rubber | Air, Argon, Helium, Krypton, Neon, Steam, Water, Xenon | 4817K16 | 000000 | 4817K26 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vacuum Breakers for Chemicals

Diaphragm Check Valve

Material | CPVC Body | PVC Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | Outlet Pipe SIze | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Min. Opening Pressure, psi | End-to-End Lg. | Seal | DIaphragm | For Use With | Temp. Range, ° F | Color | Each | Temp. Range, ° F | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1/2 | 80 | Not Rated | 100 psi @ 75° F | 1 | 4 5/16" | Fluoroelastomer | Fluoroelastomer | Beverage, Food, Air, Ammonia, Argon, Carbon Dioxide, Chlorinated Water, Diesel Fuel, Drinking Water, Ethylene Glycol, Helium, Hydrochloric Acid, Kerosene, Krypton, Liquid Carbon Dioxide, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Water, Xenon | 40 to 180 | Light Gray | 1868N13 | 0000000 | 40 to 140 | Gray | 1868N1 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 3/4 | 80 | Not Rated | 100 psi @ 75° F | 1 | 4 5/8" | Fluoroelastomer | Fluoroelastomer | Beverage, Food, Air, Ammonia, Argon, Carbon Dioxide, Chlorinated Water, Diesel Fuel, Drinking Water, Ethylene Glycol, Helium, Hydrochloric Acid, Kerosene, Krypton, Liquid Carbon Dioxide, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Water, Xenon | 40 to 180 | Light Gray | 1868N14 | 000000 | 40 to 140 | Gray | 1868N11 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1 | 80 | Not Rated | 100 psi @ 75° F | 1 | 5 1/8" | Fluoroelastomer | Fluoroelastomer | Beverage, Food, Air, Ammonia, Argon, Carbon Dioxide, Chlorinated Water, Diesel Fuel, Drinking Water, Ethylene Glycol, Helium, Hydrochloric Acid, Kerosene, Krypton, Liquid Carbon Dioxide, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Water, Xenon | 40 to 180 | Light Gray | 1868N15 | 000000 | 40 to 140 | Gray | 1868N12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spring-Loaded Piston Check Valve

Material | CPVC Body | PVC Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | Outlet Pipe SIze | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Min. Opening Pressure, psi | End-to-End Lg. | Seal | Piston | Spring | For Use With | Temp. Range, ° F | Color | Each | Temp. Range, ° F | Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 1 1/2 | 80 | Not Rated | 100 psi @ 75° F | 1 | 7 15/16" | Fluoroelastomer | CPVC | Polymer | Beverage, Food, Air, Ammonia, Argon, Carbon Dioxide, Chlorinated Water, Diesel Fuel, Drinking Water, Ethylene Glycol, Helium, Hydrochloric Acid, Kerosene, Krypton, Liquid Carbon Dioxide, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Water, Xenon | 40 to 180 | Light Gray | 1868N18 | 0000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 2 | 80 | Not Rated | 100 psi @ 75° F | 1 | 8 1/2" | Fluoroelastomer | PVC | Polymer | Beverage, Food, Air, Ammonia, Argon, Carbon Dioxide, Chlorinated Water, Diesel Fuel, Drinking Water, Ethylene Glycol, Helium, Hydrochloric Acid, Kerosene, Krypton, Liquid Carbon Dioxide, Methanol (Methyl Alcohol), Methyl Ethyl Ketone (MEK), Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Soap Solutions, Sodium Hydroxide (Caustic Soda), Sodium Hypochlorite (Bleach), Water, Xenon | — | — | ——— | 0 | 40 to 140 | Gray | 1868N17 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Pressure Vacuum Breakers

316 Stainless Steel Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | Outlet Pipe SIze | Flow Coefficient (Cv) | Max. Pressure @ Temp. | End-to-End Lg. | Specs. Met | Seal Material | For Use With | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet × NPT Male Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 3/4 | 4.6 | 1,500 psi @ 70° F | 1 5/16" | ASME B1.20.1 | Fluoroelastomer | Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon | -10 to 400 | 8537T74 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1 | 6.6 | 1,500 psi @ 70° F | 1 7/8" | ASME B1.20.1 | Fluoroelastomer | Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon | -10 to 400 | 8537T76 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

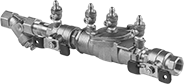

Threaded Two-Stage Backflow-Prevention Valves for Drinking Water

Pipe Size | Max. Pressure @ Temp. | Min. Opening Pressure, psi | Temp. Range, ° F | End-to-End Lg. | Food Industry Std. | For Use With | Seal Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Brass Body—Dual Check, Single Union | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 175 psi @ 180° F | 5 | 35 to 180 | 3 3/4" | NSF/ANSI 61 | Drinking Water | EPDM | 49235K81 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 175 psi @ 180° F | 5 | 35 to 180 | 3 3/4" | NSF/ANSI 61 | Drinking Water | EPDM | 49235K82 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 175 psi @ 180° F | 5 | 35 to 180 | 3 3/4" | NSF/ANSI 61 | Drinking Water | EPDM | 49235K91 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body—Dual Check, Double Union | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 175 psi @ 180° F | 5 | 35 to 180 | 3 3/4" | NSF/ANSI 61 | Drinking Water | EPDM | 9117K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 175 psi @ 180° F | 5 | 35 to 180 | 3 3/4" | NSF/ANSI 61 | Drinking Water | EPDM | 9117K42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 175 psi @ 180° F | 5 | 35 to 180 | 4" | NSF/ANSI 61 | Drinking Water | EPDM | 9117K43 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vacuum Breakers with Garden-Hose Fittings

Brass Body | Chrome-Plated Brass Body | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Hose Size | Outlet Hose Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | End-to-End Lg. | Food Industry Std. | Specs. Met | Certification | Seal Material | For Use With | Temp. Range, ° F | Each | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GHT Female Inlet × GHT Male Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Set Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 3/4 | Not Rated | 125 psi @ 70° F | 1 1/2" | — | ASME A112.1.3, ASSE 1001, ASSE 1011, CAN/CSA-B64.2, UPC Compliant | CSA Certified IAPMO Listed | Rubber | Water | 30 to 180 | 46605K55 | 000000 | 30 to 180 | 46605K58 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 3/4 | Not Rated | 125 psi @ 70° F | 1 1/2" | NSF/ANSI 372 | ASME A112.1.3, ASSE 1001, ASSE 1011, CAN/CSA-B64.2, UPC Compliant | CSA Certified IAPMO Listed | Rubber | Water | — | ——— | 0 | 30 to 180 | 46605K13 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tamper-Resistant Set Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 3/4 | Not Rated | 125 psi @ 70° F | 1 1/2" | — | ASME A112.1.3, ASSE 1001, ASSE 1011, CAN/CSA-B64.2, UPC Compliant | CSA Certified IAPMO Listed | Rubber | Water | 30 to 180 | 46605K75 | 00000 | 30 to 180 | 46605K85 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 3/4 | Not Rated | 125 psi @ 70° F | 1 1/2" | NSF/ANSI 372 | ASME A112.1.3, ASSE 1001, ASSE 1011, CAN/CSA-B64.2, UPC Compliant | CSA Certified IAPMO Listed | Rubber | Water | 33 to 180 | 46605K121 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

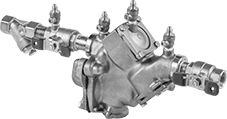

Easy-Maintenance Threaded Two-Stage Backflow-Prevention Valves for Drinking Water

Pipe Size | Max. Pressure @ Temp. | Min. Opening Pressure, psi | Temp. Range, ° F | End-to-End Lg. | Features | Specs. Met | Food Industry Std. | Certification | For Use With | Seal Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bronze Body—Dual Check | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 175 psi @ 180° F | 30 | 35 to 180 | 12 3/4" | Strainer | ASSE 1015 | NSF/ANSI 61 | CSA Certified, USC Foundation Approved | Drinking Water | Buna-N | 4775K61 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 175 psi @ 180° F | 30 | 35 to 180 | 14 5/16" | Strainer | ASSE 1015 | NSF/ANSI 61 | CSA Certified, USC Foundation Approved | Drinking Water | Buna-N | 4775K62 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 175 psi @ 180° F | 30 | 35 to 180 | 17" | Strainer | ASSE 1015 | NSF/ANSI 61 | CSA Certified, USC Foundation Approved | Drinking Water | Buna-N | 4775K63 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 175 psi @ 180° F | 30 | 35 to 180 | 21 5/8" | Strainer | ASSE 1015 | NSF/ANSI 61 | CSA Certified, USC Foundation Approved | Drinking Water | Buna-N | 4775K64 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 175 psi @ 180° F | 30 | 35 to 180 | 24 13/16" | Strainer | ASSE 1015 | NSF/ANSI 61 | CSA Certified, USC Foundation Approved | Drinking Water | Buna-N | 4775K65 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—Reduced Pressure Zone | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 175 psi @ 180° F | 30 | 35 to 180 | 12 3/4" | Relief Valve, Strainer | ASSE 1013 | NSF/ANSI 61 | USC Foundation Approved | Drinking Water | Buna-N | 47845K25 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 175 psi @ 140° F | 30 | 35 to 140 | 18 1/16" | Air Inlet, Relief Valve, Strainer | ASSE 1013 | NSF/ANSI 61 | USC Foundation Approved | Drinking Water | Buna-N | 4777K81 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 175 psi @ 180° F | 30 | 35 to 180 | 16 15/16" | Relief Valve, Strainer | ASSE 1013 | NSF/ANSI 61 | USC Foundation Approved | Drinking Water | Buna-N | 45265K41 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 175 psi @ 140° F | 30 | 35 to 140 | 19 5/8" | Air Inlet, Relief Valve, Strainer | ASSE 1013 | NSF/ANSI 61 | USC Foundation Approved | Drinking Water | Buna-N | 4777K82 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 175 psi @ 180° F | 30 | 35 to 180 | 18 1/4" | Relief Valve, Strainer | ASSE 1013 | NSF/ANSI 61 | USC Foundation Approved | Drinking Water | Buna-N | 45265K42 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4 | 175 psi @ 180° F | 30 | 35 to 180 | 21 13/16" | Relief Valve, Strainer | ASSE 1013 | NSF/ANSI 61 | USC Foundation Approved | Drinking Water | Buna-N | 45265K43 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 175 psi @ 180° F | 30 | 35 to 180 | 22 3/4" | Relief Valve, Strainer | ASSE 1013 | NSF/ANSI 61 | USC Foundation Approved | Drinking Water | Buna-N | 45265K44 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 175 psi @ 180° F | 30 | 35 to 180 | 26 11/16" | Relief Valve, Strainer | ASSE 1013 | NSF/ANSI 61 | USC Foundation Approved | Drinking Water | Buna-N | 45265K45 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Inlet × NPT Male Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 175 psi @ 140° F | 30 | 35 to 140 | 24 3/8" | Air Inlet, Relief Valve, Strainer | ASSE 1013 | NSF/ANSI 61 | USC Foundation Approved | Drinking Water | Buna-N | 4777K83 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 175 psi @ 140° F | 30 | 35 to 140 | 25 15/16" | Air Inlet, Relief Valve, Strainer | ASSE 1013 | NSF/ANSI 61 | USC Foundation Approved | Drinking Water | Buna-N | 4777K84 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Two-Stage Backflow-Prevention Valves

Pipe Size | Max. Pressure @ Temp. | Min. Opening Pressure, psi | Temp. Range, ° F | End-to-End Lg. | Vent Connection | Features | Specs. Met | Certification | For Use With | Disc Material | Seal Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Brass Body—Dual Check | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 175 psi @ 250° F | 25 | 35 to 250 | 4 15/16" | Threaded | Strainer | ASSE 1012 | CSA Certified | Air, Water | EPDM | EPDM | 4760K51 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 175 psi @ 250° F | 25 | 35 to 250 | 4 1/2" | Threaded | Strainer | ASSE 1012 | CSA Certified | Air, Water | EPDM | EPDM | 4760K52 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chrome-Plated Brass Body—Dual Check | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Inlet × NPT Female Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 150 psi @ 140° F | 25 | 35 to 140 | 2 3/8" | Unthreaded | — | ASSE 1035 | CSA Certified | Air, Water | EPDM | EPDM | 4760K63 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two-Stage Backflow-Prevention Valves with Solder-Socket Fittings

Vent Port | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Copper Tube Size | For Tube OD | Max. Pressure @ Temp. | Min. Opening Pressure, psi | Temp. Range, ° F | End-to-End Lg. | Vent Connection | Gender | Pipe Size | Thread Type | Features | For Use With | Disc Material | Seal Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Solder Socket × Solder Socket | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 5/8" | 175 psi @ 250° F | 25 | 35 to 250 | 4 3/8" | Threaded | Female | 1/2 | NPT | Strainer | Air, Water | EPDM | EPDM | 4760K66 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 7/8" | 175 psi @ 250° F | 25 | 35 to 250 | 4 13/16" | Threaded | Female | 1/2 | NPT | Strainer | Air, Water | EPDM | EPDM | 4760K67 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Freeze-Resistant Vacuum Breakers with Garden-Hose Threads

Inlet | Outlet | Brass | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Hose Size | Thread Type | Gender | Hose Size | Thread Type | Gender | Max. Pressure @ Temp. | For Use Outdoors | Specs. Met | Certification | Temp. Range, ° F | Each | |||

| 2" | 3/4 | GHT | Female | 3/4 | GHT | Male | 125 psi @ 70° F | Yes | ASME A112.1.3, ASSE 1011, CAN/CSA-B64.2 | CSA Certified | 35 to 180 | 46605K88 | 000000 | ||