Filter by

Depth

Finish

For Use On

Step Tread

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Load Capacity

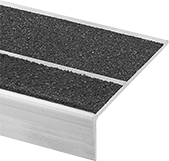

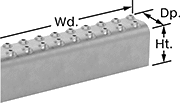

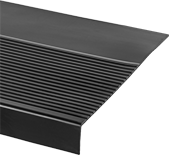

Stair Nosing

Style | Dp. | Ht. | Thk. | Material | Mounting Hardware Included | For Use On | For Use Outdoors | Choose a Grit Color | 36" Wide | 42" Wide | 48" Wide | 60" Wide | 72" Wide | 96" Wide | 144" Wide | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

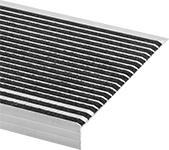

Grit Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3" | 13/16" | 3/16" | Aluminum | No | Concrete, Wood | Yes | Black | 0000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 0000000 | — | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 2 7/8" | 1/4" | 1/4" | Aluminum | No | Concrete | Yes | Black , Yellow | 0000000 | 00000 | 00000 | 00000 | 00000 | 00000 | — | — | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3" | 1" | 1/8" | Fiberglass | No | Concrete, Wood | Yes | Yellow | 0000000 | 00000 | 00000 | 00000 | 00000 | 000000 | — | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

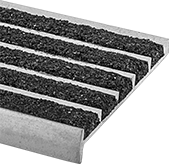

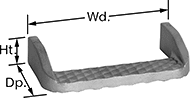

Stair Tread Covers

|  |  |

Style A | Style B | Style C |

|  |  |

Style D | Style E | Style F |

| ||

Style G |

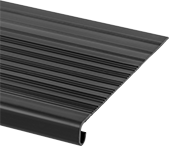

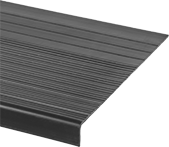

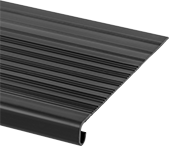

Ribbed

|  |  |

Style A | Style B | Style C |

Style | Dp. | Ht. | Thk. | Material | For Use Outdoors | Cannot Be Sold To | Choose a Color | Choose a Width | ||

|---|---|---|---|---|---|---|---|---|---|---|

| A | 9 5/8" | 7/8" | 1/8" | Vinyl Plastic | No | Washington | Black , Brown | 36" , 42" , 48" , 72" | 0000000 | |

| B | 12" | 1 1/4" | 3/16" | Vinyl Plastic | No | Washington | Black , Brown , Light Gray | 36" , 42" , 48" , 54" , 60" , 72" | 0000000 | |

| C | 12 1/4" | 1 9/16" | 1/8" | Rubber | No | — | Black , Light Gray | 36" , 42" , 48" , 54" , 60" , 72" | 0000000 |

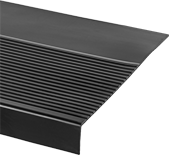

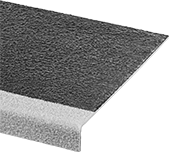

Textured

Style | Dp. | Ht. | Thk. | Material | For Use Outdoors | Choose a Color | Choose a Width | ||

|---|---|---|---|---|---|---|---|---|---|

| D | 12" | 1 7/8" | 7/32" | Rubber | No | Black , Marbled Brown , Marbled Gray | 36" , 42" , 48" , 54" , 60" , 72" | 0000000 |

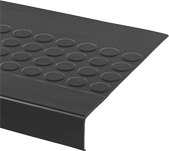

Raised Disc

Style | Dp. | Ht. | Thk. | Material | For Use Outdoors | Choose a Color | Choose a Width | ||

|---|---|---|---|---|---|---|---|---|---|

| E | 12" | 2" | 7/32" | Rubber | No | Black , Brown , Light Gray | 36" , 42" , 48" , 54" , 60" , 72" | 0000000 |

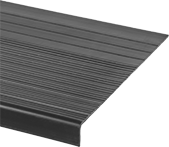

Grit

Style | Dp. | Ht. | Thk. | Material | Visibility | Mounting Hardware Included | For Use Outdoors | Choose a Grit Color | Choose a Width | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| F | 8 7/8" | 1 1/8" | 9/32" | Aluminum | — | No | Yes | Black , Black/Yellow , Light Gray | 36" , 42" , 48" , 54" , 60" , 72" | 0000000 | |

| F | 10 7/8" | 1 1/8" | 9/32" | Aluminum | — | No | Yes | Black , Black/Yellow , Light Gray | 36" , 42" , 48" , 54" , 60" , 72" | 0000000 | |

| G | 12" | 1 1/2" | 1/8" | Fiberglass | Glow-in-the-Dark | No | Yes | Dark Gray with Yellow Nosing | 36" , 42" , 48" , 54" , 60" , 72" | 0000000 |

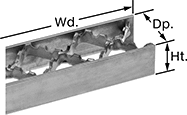

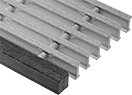

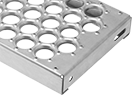

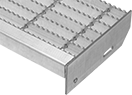

Metal Plank Grating Stair Treads

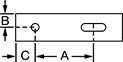

Drainage Opening | Mounting Hole | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Dp. | Top Projection | Ht. | Thk. | Dia. | Wd. | Lg. | Load Cap., lb. | No. of | Dia. | Lg. | Wd. | Ctr.-to-Ctr. (A) | Ctr.-to-Tread Top (B) | Ctr.-to-Tread Nosing (C) | Mounting Hardware Included | For Use Outdoors | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surface Projections | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mounting Dimensions | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 10" | — | 2" | 3/32" | 1 3/8" | — | — | 544 | 4 | 7/16" | 1 3/4" | 7/16" | 7" | 1" | 1 1/8" | No | No | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 12" | — | 2" | 3/32" | 1 3/8" | — | — | 372 | 4 | 7/16" | 1 3/4" | 7/16" | 9" | 1" | 1 1/8" | No | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 10" | — | 2" | 3/32" | 1 3/8" | — | — | 544 | 4 | 7/16" | 1 3/4" | 7/16" | 7" | 1" | 1 1/8" | No | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 10" | — | 2" | 3/32" | 1 3/8" | — | — | 544 | 4 | 7/16" | 1 3/4" | 7/16" | 7" | 1" | 1 1/8" | No | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 12" | — | 2" | 3/32" | 1 3/8" | — | — | 372 | 4 | 7/16" | 1 3/4" | 7/16" | 9" | 1" | 1 1/8" | No | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 12" | — | 2" | 3/32" | 1 3/8" | — | — | 372 | 4 | 7/16" | 1 3/4" | 7/16" | 9" | 1" | 1 1/8" | No | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 10" | — | 2" | 3/32" | 1 3/8" | — | — | 544 | 4 | 7/16" | 1 3/4" | 7/16" | 7" | 1" | 1 1/8" | No | Yes | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 12" | — | 2" | 3/32" | 1 3/8" | — | — | 372 | 4 | 7/16" | 1 3/4" | 7/16" | 9" | 1" | 1 1/8" | No | Yes | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 10" | — | 2" | 3/32" | 1 3/8" | — | — | 544 | 4 | 7/16" | 1 3/4" | 7/16" | 7" | 1" | 1 1/8" | No | Yes | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 10" | — | 2" | 3/32" | 1 3/8" | — | — | 544 | 4 | 7/16" | 1 3/4" | 7/16" | 7" | 1" | 1 1/8" | No | Yes | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 12" | — | 2" | 3/32" | 1 3/8" | — | — | 372 | 4 | 7/16" | 1 3/4" | 7/16" | 9" | 1" | 1 1/8" | No | Yes | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 12" | — | 2" | 3/32" | 1 3/8" | — | — | 372 | 4 | 7/16" | 1 3/4" | 7/16" | 9" | 1" | 1 1/8" | No | Yes | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mounting Dimensions | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 7" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | — | 4 | 7/16" | 1 3/4" | 7/16" | 3 3/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 9 1/2" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | — | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 11 3/4" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | — | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 7" | 5/16" | 1 1/2" | 3/64" | — | 5/8" | 1 3/4" | 524 | 4 | 7/16" | 1 3/4" | 7/16" | 3 3/8" | 3/4" | 27/32" | No | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 7" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 566 | 4 | 7/16" | 1 3/4" | 7/16" | 3 3/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 9 1/2" | 5/16" | 1 1/2" | 3/64" | — | 5/8" | 2 3/4" | 525 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 9 1/2" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 593 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 11 3/4" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 586 | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 7" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 453 | 4 | 7/16" | 1 3/4" | 7/16" | 3 3/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 9 1/2" | 5/16" | 1 1/2" | 3/64" | — | 5/8" | 3 3/4" | 421 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 9 1/2" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 474 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 11 3/4" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 469 | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 7" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 377 | 4 | 7/16" | 1 3/4" | 7/16" | 3 3/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 9 1/2" | 5/16" | 1 1/2" | 5/64" | — | 5/8" | 4 3/4" | 352 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 9 1/2" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 395 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 11 3/4" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 391 | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 3/4" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 9 1/2" | 5/16" | 2" | 5/64" | — | 1 7/8" | 11/16" | 476 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 1" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 11 3/4" | 5/16" | 2" | 5/64" | — | 1 7/8" | 11/16" | 476 | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 1" | 27/32" | No | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 7" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | — | 4 | 7/16" | 1 3/4" | 7/16" | 3 3/8" | 3/4" | 27/32" | No | Yes | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 9 1/2" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | — | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 11 3/4" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | — | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 7" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 566 | 4 | 7/16" | 1 3/4" | 7/16" | 3 3/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 9 1/2" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 474 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 11 3/4" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 586 | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 7" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 453 | 4 | 7/16" | 1 3/4" | 7/16" | 3 3/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 9 1/2" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 395 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 11 3/4" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 469 | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 7" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 377 | 4 | 7/16" | 1 3/4" | 7/16" | 3 3/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 9 1/2" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 339 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 9 1/2" | 5/16" | 2" | 5/64" | — | 1 7/8" | 11/16" | 634 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 1" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 11 3/4" | 5/16" | 1 1/2" | 5/64" | — | 1 7/8" | 11/16" | 391 | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 3/4" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 11 3/4" | 5/16" | 2" | 5/64" | — | 1 7/8" | 11/16" | 544 | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 1" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 9 1/2" | 5/16" | 2" | 5/64" | — | 1 7/8" | 11/16" | 476 | 4 | 7/16" | 1 3/4" | 7/16" | 5 7/8" | 1" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 11 3/4" | 5/16" | 2" | 5/64" | — | 1 7/8" | 11/16" | 476 | 4 | 7/16" | 1 3/4" | 7/16" | 8 1/8" | 1" | 27/32" | No | Yes | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

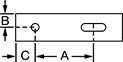

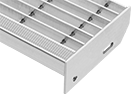

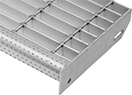

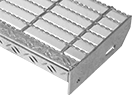

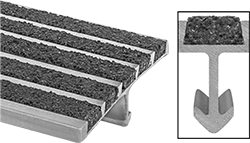

Metal Bar Grating Stair Treads

|  |  |  |

Smooth Powder-Coated Steel | Smooth Galvanized Steel | Smooth Aluminum | Smooth 304 Stainless Steel |

|  |  |  |

Serrated Powder-Coated Steel | Serrated Galvanized Steel | Serrated Aluminum | Mounting Dimensions |

Drainage Opening | Mounting Hole | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Dp. | Ht. | Thk. | Bearing Bar Ht. | Wd. | Lg. | Load Cap., lb. | No. of | Dia. | Lg. | Wd. | Ctr.-to-Ctr. (A) | Ctr.-to-Tread Top (B) | Ctr.-to-Tread Nosing (C) | Mounting Hardware Included | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Smooth | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 8 9/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 1 3/4" | 1 1/8" | No | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 9 3/4" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 8 9/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 1 3/4" | 1 1/8" | No | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 9 3/4" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 10 15/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 9 3/4" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 12 1/8" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 9 3/4" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 8 9/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 1 3/4" | 1 1/8" | No | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 9 3/4" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 8 9/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 1 3/4" | 1 1/8" | No | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 9 3/4" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 10 15/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 9 3/4" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 8 9/16" | 3" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 2 1/4" | 1 1/8" | No | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 7 3/8" | 3" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 2 1/4" | 1 1/8" | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 8 9/16" | 3" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 2 1/4" | 1 1/8" | No | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 8 9/16" | 3" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 2 1/4" | 1 1/8" | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 9 3/4" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 12 1/8" | 2 1/2" | 3/16" | 1" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 12 1/8" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 8 9/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 1 3/4" | 1 1/8" | No | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 9 3/4" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 8 9/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 1 3/4" | 1 1/8" | No | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 9 3/4" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 10 15/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32" | 10 15/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 9 3/4" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42" | 9 3/4" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 8 9/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 1 3/4" | 1 1/8" | No | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 9 3/4" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 8 9/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 1 3/4" | 1 1/8" | No | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 9 3/4" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 10 15/16" | 2 1/2" | 3/16" | 1" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 9 3/4" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48" | 10 15/16" | 2 1/2" | 3/16" | 1 1/4" | 1" | 3 13/16" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 7" | 1 3/4" | 1 1/8" | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 8 9/16" | 3" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 2 1/4" | 1 1/8" | No | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 7 3/8" | 3" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 2 1/4" | 1 1/8" | No | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 8 9/16" | 3" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 2 1/4" | 1 1/8" | No | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 8 9/16" | 3" | 3/16" | 1 1/4" | 1" | 3 3/4" | 300 | 4 | 7/16" | 1 7/16" | 7/16" | 4 1/2" | 2 1/4" | 1 1/8" | No | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

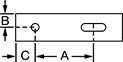

Stair Nosing for Wet Concrete

|  |

Style A | Style B |

Style | Dp. | Ht. | Thk. | Material | For Use On | For Use Outdoors | Features | Choose a Grit Color | 36" Wide | 42" Wide | 48" Wide | 60" Wide | 72" Wide | 144" Wide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Grit Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 2 7/8" | 1/4" | 1/4" | Aluminum | Wet Concrete | Yes | Integral Anchor | Black , Yellow | 0000000 | 000000 | 000000 | 000000 | 000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grit Coated, Textured | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 2 11/16" | 3/8" | 5/16" | Aluminum | Wet Concrete | Yes | Integral Anchor | — | 0000000 | 00000 | 00000 | 000000 | 000000 | 000000 | — | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3 11/16" | 3/8" | 5/16" | Aluminum | Wet Concrete | Yes | Integral Anchor | — | 0000000 | 00000 | 000000 | 000000 | 000000 | 000000 | — | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

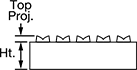

Ladder-Style Steps

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Weight Capacity | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 1/8" | 540 lb. | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 7/8" | 540 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 7/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 20 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 20 ft. | 1 7/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 250 lb. for 18" to 24" Cut Lengths, 330 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 330 lb. for 18" to 24" Cut Lengths, 450 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 570 lb. for 18" to 24" Cut Lengths, 760 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 250 lb. for 18" to 24" Cut Lengths, 330 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 330 lb. for 18" to 24" Cut Lengths, 450 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 570 lb. for 18" to 24" Cut Lengths, 760 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 17" | 2" | 540 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 7 ft. | 2" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 220 lb. for 18" to 24" Cut Lengths, 290 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 310 lb. for 18" to 24" Cut Lengths, 410 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 540 lb. for 18" to 24" Cut Lengths, 720 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 1/8" | 540 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 230 lb. for 18" to 24" Cut Lengths, 300 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 380 lb. for 18" to 24" Cut Lengths, 510 lb. Up to 18" Cut Lengths | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

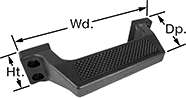

Step Handles

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Material | Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Color | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Ctr.-to-Ctr. Wd. | Assembly | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bolt On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Plastic | 1 5/8" | 6 3/8" | 2 1/2" | 3 1/4" | 1 1/8" | Diamond Tread | 2 1/2" | 0.22 | Black | No | 4 | 1/4" | 3/4" | 5 1/2" | Assembled | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Weld On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Steel | 1 3/4" | 7 3/4" | 4 1/8" | 6 3/4" | 1 5/8" | Diamond Tread | 4 1/8" | 3.2 | — | — | — | — | — | — | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum | 1 5/8" | 7 3/4" | 4 1/8" | 7" | 1 5/8" | Diamond Tread | 4 1/8" | 1.12 | — | — | — | — | — | — | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

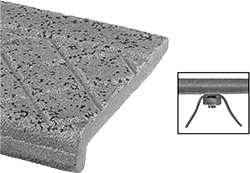

Fiberglass Stair Treads

Drainage Opening | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Dp. | Thk. | Bearing Bar Ht. | Wd. | Lg. | Load Cap., lb. | Mounting Hardware Included | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grit Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fiberglass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 10 1/2" | 1/8" | 1" | 0.9" | 5 1/2" | 500 | No | Yes | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 10 1/2" | 1/8" | 1 1/2" | 0.9" | 5 1/2" | 500 | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 10 1/2" | 1/8" | 1" | 0.9" | 5 1/2" | 250 | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 10 1/2" | 1/8" | 1 1/2" | 0.9" | 5 1/2" | 500 | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 10 1/2" | 1/8" | 1" | 0.9" | 5 1/2" | 250 | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 10 1/2" | 1/8" | 1 1/2" | 0.9" | 5 1/2" | 500 | No | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||