Filter by

Face Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

About Composites

Compare our offering of composites to find the right material for you.

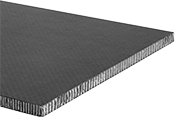

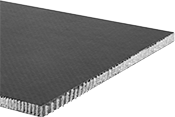

Composite Fiber Aramid Honeycomb Panels

12" × 12" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Honeycomb Cell Size | Face Color | Temp. Range, ° F | Yield Strength | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Fiber Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.03" to 0.03" | 0.125" | Black | -100 to 250 | Not Rated | No | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.03" to 0.03" | 0.125" | Black | -100 to 250 | Not Rated | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.06" to 0.06" | 0.125" | Black | -100 to 250 | Not Rated | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fiberglass Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.03" to 0.03" | 0.125" | Black | -100 to 250 | Not Rated | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.03" to 0.03" | 0.125" | Black | -100 to 250 | Not Rated | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.06" to 0.06" | 0.125" | Black | -100 to 250 | Not Rated | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

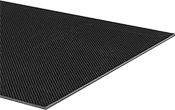

Impact-Resistant High-Strength Carbon Fiber Sheets with Kevlar Core

12" Wide × 12" Long | 24" Wide × 24" Long | 24" Wide × 48" Long | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Pattern | Appearance | Color | Temp. Range, ° F | Tensile Strength | Impact Strength | Hardness | For Use Outdoors | Each | Each | Each | |||||

| 0.06" | -0.03" to 0.03" | Checked | Glossy | Black | -100 to 190 | 177,000 psi (Excellent) | Not Rated | Not Rated | No | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | ||

| 0.09" | -0.03" to 0.03" | Checked | Glossy | Black | -100 to 190 | 177,000 psi (Excellent) | Not Rated | Not Rated | No | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | ||