About Composites

More

About Plastic

More

Wear-Resistant Nylon Film

- Color: Semi-Clear Off-White

- Max. Temperature: 450° F

- Tensile Strength: 11,200-12,300 psi (Good)

- Impact Strength: 0.6-1.4 ft.-lbs./in. (Poor)

- Hardness: Rockwell R108-R121 (Hard)

- For Use Outdoors: No

- Specifications Met: UL 94 V-2

Use this nylon 6/6 film as a protective barrier against wear. It has a slippery surface that reduces friction.

| Thick. | Thick. Tolerance | Each | |

12" × 12" | |||

|---|---|---|---|

| 0.001" | -0.0003" to 0.0003" | 00000000 | 00000 |

| 0.002" | -0.0004" to 0.0004" | 00000000 | 0000 |

12" × 24" | |||

| 0.001" | -0.0003" to 0.0003" | 00000000 | 0000 |

| 0.002" | -0.0004" to 0.0004" | 00000000 | 0000 |

12" × 48" | |||

| 0.001" | -0.0003" to 0.0003" | 00000000 | 0000 |

| 0.002" | -0.0004" to 0.0004" | 00000000 | 0000 |

24" × 24" | |||

| 0.001" | -0.0003" to 0.0003" | 00000000 | 0000 |

| 0.002" | -0.0004" to 0.0004" | 00000000 | 0000 |

24" × 48" | |||

| 0.001" | -0.0003" to 0.0003" | 00000000 | 0000 |

| 0.002" | -0.0004" to 0.0004" | 00000000 | 00000 |

Heavy Duty Antistatic Electrical Tape

Twice as thick as our standard antistatic electrical tape, this tape is made of abrasion-resistant aramid and antistatic PTFE. Use it for high-temperature wrapping where static can be a problem. This tape is chemical- and UV-resistant and will stand up to harsh environments.

| Wd. | Overall Thick. | Material | Adhesive Type | Temperature Range, °F | Voltage Rating | Color | Each | |

15 ft. | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2" | 0.007" | PTFE-Coated Aramid Fiber | Silicone | -100° to 500° | Not Rated | Black | 0000000 | 000000 |

| 1" | 0.007" | PTFE-Coated Aramid Fiber | Silicone | -100° to 500° | Not Rated | Black | 0000000 | 00000 |

| 2" | 0.007" | PTFE-Coated Aramid Fiber | Silicone | -100° to 500° | Not Rated | Black | 0000000 | 000000 |

54 ft. | ||||||||

| 1/2" | 0.007" | PTFE-Coated Aramid Fiber | Silicone | -100° to 500° | Not Rated | Black | 0000000 | 00000 |

| 1" | 0.007" | PTFE-Coated Aramid Fiber | Silicone | -100° to 500° | Not Rated | Black | 0000000 | 000000 |

| 2" | 0.007" | PTFE-Coated Aramid Fiber | Silicone | -100° to 500° | Not Rated | Black | 0000000 | 000000 |

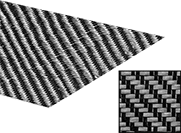

Composite Fabrics

Use these resin-free fabrics to reinforce or repair existing composites as well as create new composites. Mold custom-shaped composite parts by layering your choice of fabric with an epoxy. The epoxy (sold separately) is a two-part resin that begins to harden in 15 hours and reaches full strength in 4 days. Finished composite pieces withstand temperatures up to 250° or 350° F.

Fabrics with a plain, twill, or triaxial weave have fibers that are woven in alternating directions for uniform strength and rigidity in all directions. Easier to machine than fabrics with a unidirectional weave, their woven pattern holds the fibers together to limit splintering. Twill-weave fabrics are stronger than plain-weave fabrics. They’re also more flexible, making them easier to manipulate into complex shapes. They will not, however, retain their shape as well as plain-weave fabrics.

Kevlar fabrics are a super-tough material that offers excellent wear and abrasion resistance.