Machine-Your-Own Inside-Grip 5C Collets

The head on these collets acts like a mandrel to support the inside of a hollow workpiece. An expanding screw widens the head to firmly grip the workpiece. It can be machined to fit the exact ID of your part. All have external threads.

| Head Dia. | Head Thick. | Min. Machined Dia. | Body Dia. | Overall Lg. | External Thread Size | TIR (Total Indicated Runout) Accuracy | Material | Each | |

| 1/2" | 1" | 0.25" | 1 1/4" | 4 1/2" | 1.234"-20 | 0.0005" | Steel | 0000000 | 000000 |

| 1" | 1" | 0.437" | 1 1/4" | 4 1/2" | 1.234"-20 | 0.0005" | Steel | 0000000 | 00000 |

| 1" | 2" | 0.437" | 1 1/4" | 5 1/2" | 1.234"-20 | 0.0005" | Steel | 0000000 | 000000 |

| 1 1/2" | 1" | 0.75" | 1 1/4" | 4 1/2" | 1.234"-20 | 0.0005" | Steel | 0000000 | 00000 |

| 1 1/2" | 1 1/2" | 0.75" | 1 1/4" | 5" | 1.234"-20 | 0.0005" | Steel | 0000000 | 000000 |

| 2" | 1" | 0.75" | 1 1/4" | 4 1/2" | 1.234"-20 | 0.0005" | Steel | 0000000 | 000000 |

| 2" | 1 1/2" | 0.75" | 1 1/4" | 5" | 1.234"-20 | 0.0005" | Steel | 0000000 | 000000 |

| 2 1/2" | 2 1/2" | 0.75" | 1 1/4" | 6" | 1.234"-20 | 0.0005" | Steel | 0000000 | 000000 |

Expanding-End Lathe Mandrels

An expanding screw widens the end of the mandrel for a tight hold on the inside of a workpiece. These mandrels are machinable to fit the exact ID of your part. Mandrels are also known as arbors.

| OD | Overall Lg. | Shank Dia. | End Expansion | Material | Each | |

| 1/4" | 3" | 1/4" | 0.002" | Steel | 0000000 | 000000 |

| 3/8" | 3" | 3/8" | 0.002" | Steel | 0000000 | 00000 |

| 1/2" | 3" | 1/2" | 0.002" | Steel | 0000000 | 00000 |

| 5/8" | 3" | 5/8" | 0.002" | Steel | 0000000 | 00000 |

| 3/4" | 4" | 3/4" | 0.002" | Steel | 0000000 | 00000 |

| 7/8" | 4" | 7/8" | 0.002" | Steel | 0000000 | 00000 |

| 1" | 4" | 1" | 0.002" | Steel | 0000000 | 00000 |

| 1 1/4" | 4" | 1" | 0.002" | Steel | 0000000 | 00000 |

| 1 1/2" | 4" | 1" | 0.002" | Steel | 0000000 | 00000 |

| 1 3/4" | 4" | 1" | 0.002" | Steel | 0000000 | 00000 |

Expanding-End Lathe Mandrel Sets

An expanding screw widens the end of the mandrel for a tight hold on the inside of a workpiece. These mandrels are machinable to fit the exact ID of your part. Mandrels are also known as arbors.

| Number of Pieces | Includes | End Expansion | Material | Each | |

| 8 | Five Hex Keys One 1 1/4" OD × 1" Shank Dia × 4" Lg. Expanding-End Mandrel One 1" OD × 1" Shank Dia × 4" Lg. Expanding-End Mandrel One 1/2" OD × 1/2" Shank Dia × 3" Lg. Expanding-End Mandrel One 1/4" OD × 1/4" Shank Dia × 3" Lg. Expanding-End Mandrel One 3/4" OD × 3/4" Shank Dia × 4" Lg. Expanding-End Mandrel One 3/8" OD × 3/8" Shank Dia × 3" Lg. Expanding-End Mandrel One 5/8" OD × 5/8" Shank Dia × 3" Lg. Expanding-End Mandrel One 7/8" OD × 7/8" Shank Dia × 4" Lg. Expanding-End Mandrel Stand | 0.002" | Steel | 0000000 | 0000000 |

Solid Lathe Mandrels

Use an arbor press to secure the narrow end of one of these tapered mandrels into the hole of a workpiece. The wide end has a flat for use with a lathe driver when turning between centers. Mandrels are also known as arbors.

| OD | Overall Lg. | Taper per Inch | Tapered End Tolerance | Material | Each | |

| 1/8" | 2 1/2" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 000000 |

| 3/16" | 3" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

| 1/4" | 3 3/4" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

| 5/16" | 4" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

| 3/8" | 4 1/4" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

| 7/16" | 4 1/2" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

| 1/2" | 5" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

| 9/16" | 5 1/4" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

| 5/8" | 5 1/2" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

| 3/4" | 6" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

| 7/8" | 6 1/2" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

| 1" | 7" | 0.0005" | -0.0005" to 0" | Steel | 0000000 | 00000 |

Wide-Diameter Range Lathe Mandrels

The sleeve on these mandrels expands to hold a range of IDs for better versatility than solid and expanding-end mandrels. They can hold the workpiece at any position along the sleeve. To use, insert the sleeve into the workpiece before inserting the small end of the tapered body into the sleeve and pushing until it's tight. Mandrels are also known as arbors.

| OD | Overall Lg. | Sleeve Lg. | Sleeve Accuracy | Material | Each | |

| 1/2"-9/16" | 5" | 2 1/2" | 0.001" TIR | Steel | 0000000 | 000000 |

| 9/16"-21/32" | 6" | 2 3/4" | 0.001" TIR | Steel | 0000000 | 00000 |

| 21/32"-3/4" | 7" | 2 3/4" | 0.001" TIR | Steel | 0000000 | 00000 |

| 3/4"-7/8" | 7" | 3 1/4" | 0.001" TIR | Steel | 0000000 | 00000 |

| 7/8"-1" | 7" | 3 1/2" | 0.001" TIR | Steel | 0000000 | 00000 |

| 1"-1 1/4" | 9" | 4" | 0.001" TIR | Steel | 0000000 | 000000 |

| 1 1/4"-1 1/2" | 9" | 4" | 0.001" TIR | Steel | 0000000 | 000000 |

| 1 1/2"-2" | 11 1/2" | 5" | 0.001" TIR | Steel | 0000000 | 000000 |

| 2"-2 3/4" | 14" | 6" | 0.001" TIR | Steel | 0000000 | 000000 |

| 2 3/4"-3 3/4" | 17" | 7" | 0.001" TIR | Steel | 0000000 | 000000 |

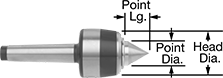

Live Centers for Continuous Use

A hardened body and point provide the extra strength and wear resistance necessary for continuous use on manual or CNC lathes. Use live centers in the tailstock to support the end of a workpiece. With bearings to support their free-turning point, they produce minimal friction between the center and workpiece. For increased tool life, the bearings are lubricated and sealed to protect against fluid and chips.

| Morse Taper Number | Max. Workpiece Capacity, lbs. | Point Dia. | Head Dia. | Point Lg. | Shank Lg. | Overall Lg. | Morse Taper Dia. | Max. Speed, rpm | Point Angle | TIR (Total Indicated Runout) Accuracy | Material | Each | |

| 2 | 725 | 7/8" | 1 3/4" | 1 1/64" | 2 13/16" | 5 19/64" | 0.7" | 6,000 | 60° | 0.00005" | Hardened Steel | 0000000 | 0000000 |

| 3 | 970 | 1" | 2 11/32" | 1 15/64" | 3 7/16" | 6 13/32" | 0.938" | 5,000 | 60° | 0.00005" | Hardened Steel | 0000000 | 000000 |

| 4 | 1,720 | 1 1/4" | 2 11/16" | 1 31/64" | 4 15/32" | 7 57/64" | 1.231" | 4,500 | 60° | 0.00005" | Hardened Steel | 0000000 | 00000000 |

| 5 | 3,260 | 1 1/2" | 3 29/64" | 1 27/32" | 5 35/64" | 10 13/64" | 1.748" | 3,500 | 60° | 0.00005" | Hardened Steel | 0000000 | 00000000 |

Live Centers for Intermittent Use

These light duty centers are for intermittent use on manual lathes. Use live centers in the tailstock to support the end of a workpiece. With bearings to support their free-turning point, they produce minimal friction between the center and workpiece. For increased tool life, the bearings are lubricated and sealed to protect against fluid and chips.

| Morse Taper Number | Max. Workpiece Capacity, lbs. | Point Dia. | Head Dia. | Point Lg. | Shank Lg. | Overall Lg. | Morse Taper Dia. | Max. Speed, rpm | Point Angle | TIR (Total Indicated Runout) Accuracy | Material | Each | |

| 1 | 220 | 0.59" | 1 1/2" | 45/64" | 2 3/32" | 4 1/16" | 0.475" | 5,000 | 60° | 0.0003" | Steel | 0000000 | 0000000 |

| 2 | 460 | 0.7" | 1 9/16" | 7/8" | 2 33/64" | 4 47/64" | 0.7" | 5,000 | 60° | 0.0003" | Steel | 0000000 | 000000 |

| 3 | 925 | 0.98" | 2 13/64" | 1 1/8" | 3 3/16" | 6 9/64" | 0.938" | 4,000 | 60° | 0.0003" | Steel | 0000000 | 000000 |

| 4 | 1,850 | 1.1" | 2 33/64" | 1 15/64" | 4 1/32" | 7 15/64" | 1.231" | 3,000 | 60° | 0.0003" | Steel | 0000000 | 000000 |

| 5 | 4,400 | 1.61" | 3 11/32" | 1 49/64" | 5 3/32" | 9 21/64" | 1.748" | 2,500 | 60° | 0.0003" | Steel | 0000000 | 000000 |

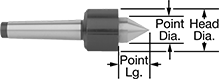

Pipe and Tubing Live Centers

Also known as bull-nose centers, these have a wide head to hold pipe and large-diameter tubing. Use live centers in the tailstock to support the end of a workpiece. With bearings to support their free-turning point, they produce minimal friction between the center and workpiece.

| Morse Taper Number | Max. Workpiece Capacity, lbs. | Point Dia. | Point Tip Dia. | Point Lg. | Shank Lg. | Overall Lg. | Morse Taper Dia. | Max. Speed, rpm | TIR (Total Indicated Runout) Accuracy | Material | Each | |

| 2 | 2,000 | 4" | 1" | 3 29/32" | 2 9/16" | 6 27/32" | 0.7" | 2,500 | 0.00015" | Hardened Steel | 0000000 | 0000000 |

| 3 | 3,800 | 4" | 1" | 3 29/32" | 3 3/16" | 7 15/32" | 0.938" | 2,500 | 0.00015" | Hardened Steel | 0000000 | 000000 |

| 4 | 4,800 | 4" | 1" | 3 29/32" | 4 1/16" | 8 11/32" | 1.231" | 2,500 | 0.00015" | Hardened Steel | 0000000 | 000000 |

| 5 | 4,800 | 4" | 1" | 3 29/32" | 5 3/16" | 9 15/32" | 1.748" | 2,500 | 0.00015" | Hardened Steel | 0000000 | 000000 |

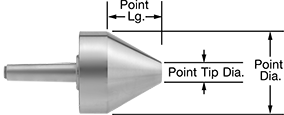

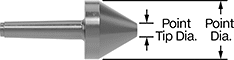

Dead Centers

Insert these in your headstock to support your workpiece when machining between centers. Unlike live centers, dead centers don’t spin freely, so they give you a fixed point to stabilize your material. You can also use them in the tailstock to support the end of the workpiece when friction isn’t a concern. Made of through-hardened 52100 alloy steel—a material originally developed for bearings—these centers have exceptional hardness, strength, and wear resistance. That means you'll have to replace them less often than centers made of low-quality steel. You can also apply high-pressure grease on the point to reduce friction and wear.

Pipe and tubing centers hold large-diameter, hollow workpieces. Also known as bull-nose centers.

Carbide-tipped hardened steel dead centers have better wear resistance than hardened steel dead centers. They’re ideal for high-volume work and holding highly abrasive and hard materials.

Hardened Steel | Carbide-Tipped Hardened Steel | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Morse Taper Number | Point Dia. | Point Tip Dia. | Point Lg. | Overall Lg. | TIR (Total Indicated Runout) Accuracy | Each | Each | ||

Dead Centers | |||||||||

| 1 | 0.475" | __ | 1 3/16" | 3 5/16" | 0.00005" | 000000 | 0000000 | 00000000 | 0000000 |

| 2 | 0.7" | __ | 1 5/8" | 4 3/16" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 3 | 0.938" | __ | 2 1/16" | 5 1/4" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 4 | 1.231" | __ | 2 11/16" | 6 3/4" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 5 | 1.748" | __ | 3 5/16" | 8 1/2" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 6 | 2.494" | __ | 4 1/4" | 11 1/2" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 7 | 3.27" | __ | 5" | 15" | 0.00005" | 0000000 | 000000 | 0000000 | 00000000 |

Dead Centers for Pipe and Tubing | |||||||||

| 2 | 2.13" | 1/2" | 2 13/32" | 5" | 0.00005" | 0000000 | 000000 | 000000 | 00 |

| 3 | 2.75" | 1" | 2 33/64" | 5 3/4" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 4 | 2.75" | 1" | 2 33/64" | 6 9/16" | 0.00005" | 0000000 | 000000 | 0000000 | 00000000 |

| 5 | 3.5" | 1" | 3 11/64" | 8 3/8" | 0.00005" | 0000000 | 000000 | 000000 | 00 |