Filter by

Pipe Size

For Use With

For Valve Control Type

Material

Valve Function

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Valve Handle Lockouts

Style A

For Pipe Size | Min. Padlock Vert. Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, ° F | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slide On—Locks in Closed and Open Position | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 to 2 1/2 (Closed) 1/2 to 1 1/4 (Open) | — | 2 | 5/16" | 0 to 175 | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 to 2 1/2 (Closed) 1/2 to 1 1/4 (Open) | 3/4" | 2 | 5/16" | 0 to 175 | Blue | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 to 2 1/2 (Closed) 1/2 to 1 1/4 (Open) | 3/4" | 2 | 5/16" | 0 to 175 | Green | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 to 2 1/2 (Closed) 1/2 to 1 1/4 (Open) | 3/4" | 2 | 5/16" | 0 to 175 | Yellow | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slide On—Locks in Closed Position | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 to 8 | 3/4" | 2 | 5/16" | 0 to 175 | Blue | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 to 8 | 3/4" | 2 | 5/16" | 0 to 175 | Green | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 to 8 | 3/4" | 2 | 5/16" | 0 to 175 | Yellow | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 to 8 | — | 2 | 5/16" | 0 to 175 | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style B

For Pipe Size | Min. Padlock Vert. Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, ° F | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slide On—Locks in Closed and Open Position | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 to 1 1/4 (Closed) 3/8 to 1 1/4 (Open) | 1" | 6 | 9/32" | -20 to 200 | Red | Yes | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 to 2 1/2 (Closed) 3/8 to 1 1/4 (Open) | 1" | 6 | 9/32" | -20 to 200 | Red | Yes | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slide On—Locks in Closed Position | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 to 8 | 1" | 5 | 9/32" | -20 to 200 | Red | Yes | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style D

For Pipe Size | Min. Padlock Vert. Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, ° F | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slide On—Locks in Closed Position | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 to 1/2 | 1" | 8 | 3/8" | -20 to 200 | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 to 1 | 1" | 8 | 9/32" | -20 to 200 | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 to 1 | 1" | 6 | 9/32" | — | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 to 1 | 1" | 8 | 9/32" | — | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 to 1 | 1" | 6 | 3/8" | -20 to 200 | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4 to 3 | 1" | 7 | 3/8" | -20 to 200 | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4 to 3 | 1" | 15 | 9/32" | -20 to 200 | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style E

For Handle Thk. | Min. Padlock Vert. Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Clamp Material | Temp. Range, ° F | Color | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Clamp On—Locks in Closed and Open Position | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" to 1/2" | 3/4" | 2 | 3/8" | 304 Stainless Steel | 0 to 245 | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" to 1" | 3/4" | 2 | 3/8" | 304 Stainless Steel | 0 to 245 | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style H

For Pipe Size | Min. Padlock Vert. Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Clamp Material | Hook Material | Temp. Range, ° F | Color | Label Included | Includes | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hook On—Locks in Closed Position | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Metal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 to 2 | 3/4" | 1 | 5/16" | 304 Stainless Steel | Steel | -40 to 190 | Red | No | Hose Clamp | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 to 4 | 3/4" | 1 | 5/16" | 304 Stainless Steel | Steel | -40 to 190 | Red | No | Hose Clamp | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Valve Stem Lockouts

Lockout Cable

Body | Cable | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Stem Dia. | For Valve Type | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Ht. | Cable Dia. | Lg., ft. | Material | Temp. Range, ° F | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" to 2 1/4" | Ball, Gate | 4 | 9/32" | 5" | 3" | 3 5/8" | 1/8" | 3 | Plastic-Coated Steel | 0 to 250 | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

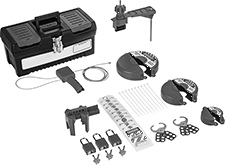

Electrical and Valve Lockout Sets with Padlocks

Lockout Type | Includes | Specs. Met | Each | ||

|---|---|---|---|---|---|

| Cover, Cable, Hasp, Bag | 1 Each: Wall Switch Lockout 1 Each: Cable Lockout 1 Each: Plug Lockout 5 Each: Circuit Breaker Lockouts Plastic Box 1 Each: Adjustable Ball Valve Lockout 1 Each: Plug Prong Lockout 3 Valve Wheel Lockouts (1 Each that fits 1"-3", 2"-5", and 4"-6 1/2" Diameter Wheels) 1 Each: Hoist Cover 3 Each: Lockout Hasps 3 Each: 1/4" Shackle Diameter Keyed Alike Padlocks with Labels 6 Each: Tags 6 Cable Ties | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

Valve Lockout Sets with Padlocks

For Valve Control Type | Includes | Specs. Met | Each | ||

|---|---|---|---|---|---|

| Hand Wheel, Handle | 10 Each: Tags 1 Each: Cable Lockout 2 Each: Lockout Hasps Plastic Box 1 Each: Adjustable Ball Valve Lockout 1 Each: Universal Valve Lockout with Blocking Arm 10 Each: Zip Ties 3 Each: 1/4" Shackle Diameter Keyed Differently Padlocks 3 Valve Wheel Lockouts (1 Each that fits 1"-2 1/2", 2 1/2"-5", and 5"-6 1/2" Diameter Wheels) | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

Wall-Mount Electrical and Valve Lockout Sets with Padlocks

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Includes | Ht. | Wd. | Dp. | Fasteners Included | No. Of | Screw Size | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Case | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 Each: Plug Lockouts 1 Each: Cable Lockout 1 Each: Snap-On Lockout Hasp 2 Each: Lockout Hasps 2 Each: Valve Handle Lockouts (Fits 3/8 to 4 Pipe Size) 2 Each: Wall Switch Lockouts 4 Valve Wheel Lockouts (1 Each that fits 1"-3", 2"-5", 4"-6 1/2", and 6"-10" Diameter Wheels) 6 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 8 Each: Circuit Breaker Lockouts 24 Each: Tags 24 Each: Cable Ties | 27" | 23 1/2" | 4 1/2" | No | 8 | No. 10 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Universal Valve Lockouts

Lockouts | Additional Blocking Arms | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nylon Cable | Vinyl-Coated Metal Cable | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Handle Thk. | Min. Padlock Vert. Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Clamp Material | Cable Dia. | Lg., ft. | Temp. Range, ° F | Color | Features | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp On—Locks in Closed Position | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" to 1/2" | 3/4" | 2 | 3/8" | Stainless Steel | 1/8" | 8 | 0 to 245 | Red | Blocking Arm | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" to 1" | 3/4" | 2 | 3/8" | Stainless Steel | 1/8" | 8 | 0 to 245 | Red | Blocking Arm | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp-On Lockout Cables

Cable | Body | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Max. Jaw Opening | Cable Dia. | Lg., ft. | Material | Lg. | Wd. | Thk. | Color | Includes | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Cable | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 9/32" | 2 3/4" | 1/8" | 8 | Plastic-Coated Steel | 8 5/8" | 7" | 2 5/8" | Red | Interchangeable Steel and Rubber Jaws | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrical, Valve, and Air Hose Lockout Sets with Padlocks

For Use With | For Valve Control Type | Includes | Specs. Met | Each | ||

|---|---|---|---|---|---|---|

| Air Hose, Circuit Breakers, Electrical Panels, Electrical Plugs, Push Buttons, Valves, Wall Switches | Hand Wheel, Handle | 1 Each: Wall Switch Lockout 2 Each: Plug Lockouts 2 Valve Wheel Lockouts (1 Each that fits 1"-2 1/2" and 2 1/2"-5" Diameter Wheels) 3 Each: Circuit Breaker Lockouts 1 Each: Cable Lockout 2 Each: Lockout Hasps 1 Each: Air Hose Lockout 1 Each: Push Button Lockout 1 Each: Valve Handle Lockout (Fits 3/8 to 1 Pipe Size) 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 5 Each: Cable Ties 5 Each: Tags Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |