Filter by

Thread Size

Material

Mount Type

Finish

Color

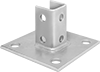

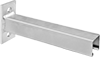

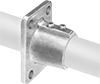

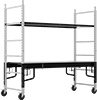

Bolt-Together Framing Component

Overall Height

Rail Height

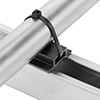

Strut Channel Type

Shape

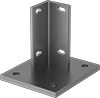

Strut Channel Framing Component

DFARS Specialty Metals

Building and Machinery Hardware

Measuring and Inspecting

Fabricating and Machining

Material Handling

Lighting

Communication

Containers, Storage, and Furniture

Power Transmission

Electrical

Fastening and Joining

Facility and Grounds Maintenance

Safety Equipment

Raw Materials

Fluid Handling

Heating, Ventilation, and Air Conditioning