Filter by

System of Measurement

Thread Size

Material

Thread Spacing

Component

Thread Type

Spanner Wrench Style

Thread Direction

REACH

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Specifications Met

Threading

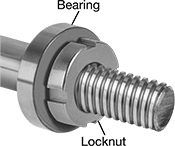

Bearing Locknuts

Bearing Nuts

Fast-Travel Ball Screws and Nuts

|  |  |

Ball Nuts, Externally Threaded Nut, Style C | Ball Nuts Flange Nut Style E |

Ball Screws—Right-Hand Threaded

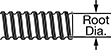

Thread Size | Lg., mm | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Root Dia., mm | Hardness | Tensile Strength, psi | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M32 | 500 | 2 | 20 | ±0.05 mm/300 mm | 28.5 | Rockwell C56 | 95,000 | 32 to 150 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M32 | 500 | 4 | 32 | ±0.05 mm/300 mm | 28.3 | Rockwell C56 | 95,000 | 32 to 150 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M32 | 1,000 | 2 | 20 | ±0.05 mm/300 mm | 28.5 | Rockwell C56 | 95,000 | 32 to 150 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M32 | 1,000 | 4 | 32 | ±0.05 mm/300 mm | 28.3 | Rockwell C56 | 95,000 | 32 to 150 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

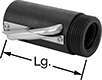

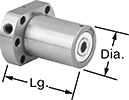

Externally Threaded Ball Nuts—Right-Hand Threaded

Style | Thread Size | Lg., mm | Dia., mm | No. of Thread Starts | Travel Distance per Turn, mm | External Thread Size | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash, mm | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M32 | 90 | 53 | 4 | 32 | M50 | Rockwell C56 | 3,700 | 0.03 | 32 to 150 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flange Ball Nuts—Right-Hand Threaded

Flange, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg., mm | Dia., mm | Dia. | Thk. | No. of Thread Starts | Travel Distance per Turn, mm | Bolt Circle Dia., mm | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash, mm | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | M32 | 88 | 53 | 86 | 14 | 4 | 32 | 71 | Rockwell C56 | 5,800 | 0.05 | 32 to 150 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | M32 | 108 | 49 | 80 | 16 | 2 | 20 | 65 | Rockwell C56 | 4,900 | 0.04 | 32 to 150 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||