Filter by

System of Measurement

ID

For Load Direction

Ball Bearing Profile

Lubrication

Cage Material

Shaft Type

Bearing Construction

For Housing ID

Dynamic Radial Load Capacity

Ball Material

Plain Bearing Type

RoHS

DFARS Specialty Metals

Ball Bearings

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | For Housing ID | Wd. | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2 1/4" | 3/8" | 1 | 2,400 | 15,000 | -20 | 230 | Standard | R20 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2 1/4" | 1/2" | Not Rated | 270 | 720 | -40 | 140 | Standard | R20 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shielded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2 1/4" | 1/2" | 1 | 2,400 | 15,000 | -20 | 230 | Standard | R20-2Z | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2 1/4" | 1/2" | 1 | 2,150 | 9,200 | -20 | 210 | Standard | R20-2Z | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2 1/4" | 1/2" | 1 | 3,150 | 7,500 | -20 | 230 | Standard | R20-2RS | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2 1/4" | 1/2" | 1 | 2,150 | 7,700 | -20 | 210 | Standard | R20-2RS | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Permanently Lubricated Ball Bearings

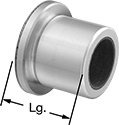

Oil-Embedded Flanged Sleeve Bearings

|

For Shaft Dia. | For Housing ID | Lg. | Flange OD | Flange Thk. | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 2 1/2" | 3" | 1/4" | 8,750 lb. @ 30 rpm | 9,300 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 3/4" | 2 1/2" | 1/8" | 3,000 lb. @ 30 rpm | 3,500 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 1 1/4" | 2 1/2" | 1/8" | 5,000 lb. @ 30 rpm | 3,500 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 2 1/2" | 1/8" | 8,000 lb. @ 30 rpm | 3,500 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 2 1/2" | 3" | 1/4" | 11,100 lb. @ 30 rpm | 6,900 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 3/4" | 2 1/2" | 1/8" | 3,300 lb. @ 30 rpm | 3,100 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 1 1/4" | 2 1/2" | 1/8" | 5,550 lb. @ 30 rpm | 3,100 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 2 1/2" | 1/8" | 8,900 lb. @ 30 rpm | 3,100 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extreme-Load Heat-Treated Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 2 1/2" | 3" | 1/4" | 23,850 lb. @ 30 rpm | 14,800 lb. @ 30 rpm | Mineral Oil | 10 to 220 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 2 1/2" | 1/8" | 19,050 lb. @ 30 rpm | 6,750 lb. @ 30 rpm | Mineral Oil | 10 to 220 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

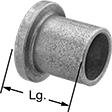

Oil-Embedded Sleeve Bearings

|

For Shaft Dia. | For Housing ID | Lg. | Dynamic Radial Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 2" | 7,000 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 2 1/2" | 8,750 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 3" | 10,500 lb. @ 30 rpm | Mineral Oil | 10 to 220 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2 1/4" | 3/4" | 2,800 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2 1/4" | 2" | 7,500 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2 1/4" | 2 1/2" | 9,350 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2 1/4" | 3" | 11,250 lb. @ 30 rpm | Mineral Oil | 10 to 220 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 2 1/4" | 2" | 7,750 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 1/2" | 2,000 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 3/4" | 3,000 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 1" | 4,000 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 1 1/2" | 6,000 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 8,000 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2 1/2" | 10,000 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 3" | 12,000 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 4" | 16,000 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 8,900 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2 1/2" | 11,100 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 4" | 17,800 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extreme-Load Heat-Treated Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 1" | 9,500 lb. @ 30 rpm | Mineral Oil | 10 to 350 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 19,050 lb. @ 30 rpm | Mineral Oil | 10 to 350 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flanged Sleeve Bearings

|

For Shaft Dia. | For Housing ID | Lg. | Flange OD | Flange Thk. | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Load 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 2 1/2" | 3" | 1/4" | 17,500 lb. @ 30 rpm | 14,800 lb. @ 30 rpm | -350 to 450 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 3/4" | 2 1/2" | 1/8" | 6,000 lb. @ 30 rpm | 6,750 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 1 1/4" | 3 1/2" | 1/8" | 10,000 lb. @ 30 rpm | 17,650 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 4 1/2" | 1/8" | 16,000 lb. @ 30 rpm | 27,050 lb. @ 30 rpm | -350 to 450 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load Chemical-Resistant 954 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 2 1/2" | 3" | 1/4" | 19,650 lb. @ 30 rpm | 20,950 lb. @ 30 rpm | -350 to 500 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sleeve Bearings

|

For Shaft Dia. | For Housing ID | Lg. | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Load 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 2 1/4" | 3" | 18,000 lb. @ 30 rpm | -350 to 450 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 1 3/4" | 12,250 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 16,000 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2 1/2" | 20,000 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 4" | 32,000 lb. @ 30 rpm | -350 to 450 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load Chemical-Resistant 954 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 1 1/2" | 13,500 lb. @ 30 rpm | -350 to 500 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Metal-Reinforced Plastic Flanged Sleeve Bearings

For Shaft Dia. | For Housing ID | Lg. | Flange OD | Flange Thk. | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

PTFE with Aluminum Shell | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 3" | 2 1/2" | 1/8" | 7,600 lb. @ 30 rpm | 1,800 lb. @ 30 rpm | -400 to 400 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Sleeve Bearings

|

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | For Housing ID | Lg. | Dynamic Radial Load Cap. @ Speed | Color | Temp. Range, ° F | 1-24 | 25-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load Ultra-Chemical-Resistant Polyester Fabric-Reinforced PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 2 1/4" | 3" | 9,500 lb. @ 30 rpm | Blue | -40 to 150 | 0000000 | 000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 6,350 lb. @ 30 rpm | Blue | -40 to 150 | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extreme-Load Ultra-Chemical-Resistant Fiberglass-Backed PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 1 1/2" | 15,150 lb. @ 30 rpm | Gray | -55 to 280 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 3" | 30,350 lb. @ 30 rpm | Gray | -55 to 280 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load Dry-Running Ball Bearings

Temp. Range, ° F | 316 Stainless Steel Balls | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | For Housing ID | Wd. | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | ABEC Rating | Bearing Trade No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2 1/4" | 3/4" | 125 | 500 | -40 | 180 | Not Rated | R20 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Low-Friction Oil-Embedded Flanged Sleeve Bearings

For Shaft Dia. | For Housing ID | Lg. | Flange OD | Flange Thk. | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Base Oil | Lubricant Additive | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 2 1/2" | 3" | 1/4" | 8,750 lb. @ 30 rpm | 9,300 lb. @ 30 rpm | Synthetic Oil | PTFE | -140 to 460 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 2 1/2" | 1/8" | 8,000 lb. @ 30 rpm | 3,500 lb. @ 30 rpm | Synthetic Oil | PTFE | -140 to 460 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grooved Sleeve Bearings

|

For Shaft Dia. | For Housing ID | Lg. | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Load 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 2 1/4" | 3" | 15,750 lb. @ 30 rpm | -350 to 450 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 1 3/4" | 10,700 lb. @ 30 rpm | -350 to 450 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 14,000 lb. @ 30 rpm | -350 to 450 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2 1/2" | 17,500 lb. @ 30 rpm | -350 to 450 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load Chemical-Resistant 954 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 15,600 lb. @ 30 rpm | -350 to 500 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2 1/2" | 19,500 lb. @ 30 rpm | -350 to 500 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Flanged Sleeve Bearings

For Shaft Dia. | For Housing ID | Lg. | Flange OD | Flange Thk. | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Color | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Load Ultra-Chemical-Resistant Polyester Fabric-Reinforced PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 2 1/2" | 1/4" | 6,350 lb. @ 30 rpm | 2,250 lb. @ 30 rpm | Blue | -40 to 150 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Graphite-Lubricated Flanged Sleeve Bearings

For Shaft Dia. | For Housing ID | Lg. | Flange OD | Flange Thk. | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 1/4" | 2 1/2" | 3" | 1/4" | 7,000 lb. @ 30 rpm | 7,450 lb. @ 30 rpm | -50 to 700 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Metal-Reinforced Plastic Sleeve Bearings

|

For Shaft Dia. | For Housing ID | Lg. | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

PTFE with Aluminum Shell | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 3" | 7,600 lb. @ 30 rpm | -400 to 400 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Graphite-Lubricated Sleeve Bearings

|

For Shaft Dia. | For Housing ID | Lg. | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 6,400 lb. @ 30 rpm | -50 to 700 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2 1/2" | 8,000 lb. @ 30 rpm | -50 to 700 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load Chemical-Resistant 954 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2" | 15,600 lb. @ 30 rpm | -350 to 500 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 2 1/2" | 19,500 lb. @ 30 rpm | -350 to 500 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||