Filter by

System of Measurement

Bearing Trade Number

Bearing Construction

Ball Bearing Profile

Ball Material

Cage Material

For Load Direction

For Housing ID

Lubrication

Lubricant

Maximum Rotation Speed

Shaft Type

DFARS Specialty Metals

Inner Ring Type

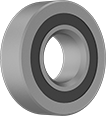

Ball Bearings

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 2,250 | 26,500 | -20 | 230 | Standard | 6203 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,450 | 17,000 | -40 | 240 | Standard | 6203 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | Not Rated | 200 | 1,000 | -40 | 140 | Standard | 6203 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shielded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 2,100 | 18,000 | -20 | 230 | Standard | 6203-2Z | 000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 3 | 2,200 | 19,000 | -20 | 230 | Standard | 6203-2Z | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,450 | 17,000 | -40 | 240 | Standard | 6203-2Z | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 2,100 | 11,100 | -20 | 230 | Standard | 6203-2RS | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 3 | 2,200 | 12,000 | -30 | 210 | Standard | 6203-2RS | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,800 | 17,000 | -40 | 240 | Standard | 6203-2RS | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Permanently Lubricated Ball Bearings

|

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,800 | 10,500 | 10 | 200 | Standard | 6203 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,650 | 10,000 | -10 | 200 | Standard | 6203 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,800 | 10,500 | 10 | 200 | Standard | 6203-2RS | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,650 | 10,000 | -10 | 200 | Standard | 6203-2RS | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Angular Contact Ball Bearings

|  |  |  |  |

Single Row Open | Single Row Sealed | Double Row Open | Double Row Shielded | Double Row Sealed |

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Material | Dynamic Combined Load Cap., lbf | Max. Rotation Speed, rpm | Lubrication | Contact Angle | Min. | Max. | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Row | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 3 | Steel | 2,300 | 20,000 | Required | 40° | -40 | 300 | 7203 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | Steel | 2,350 | 11,000 | Lubricated | 40° | -20 | 230 | 7203-2RS | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Double Row | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 17.5 | 1 | Steel | 3,200 | 15,000 | Required | 30° | -40 | 250 | 3203 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shielded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 17.5 | 1 | Steel | 3,200 | 16,000 | Lubricated | 30° | -40 | 250 | 3203-2Z | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 17.5 | 1 | Steel | 3,200 | 12,000 | Lubricated | 30° | -40 | 210 | 3203-2RS | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Self-Aligning Ball Bearings

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Misalignment Capability | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,750 | 16,000 | 4° | Not Rated | 210 | Standard | 1203 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 16 | 1 | 2,350 | 24,000 | 2.5° | -30 | 210 | Standard | 2203 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 16 | 1 | 1,950 | 12,000 | 1.5° | -30 | 210 | Standard | 2203-2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrically Insulating Ball Bearings

High-Load Dry-Running Ball Bearings

Temp. Range, ° F | 316 Stainless Steel Balls | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | ABEC Rating | Bearing Trade No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 17 | 85 | 800 | -40 | 180 | Not Rated | A5203-6 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapered-Roller Bearings

|  |

Radial Load Cap., lb. | Thrust Load Cap., lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Bearing Trade No. | Dynamic | Static | Dynamic | Static | Max. Rotation Speed, rpm | Lubrication | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Combined Radial and Thrust Load—Open with Steel Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 11 | 30203 | 1,150 | 4,450 | 680 | 4,450 | 5,400 | Required | -60 to 200 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 11 | 30203 | 4,750 | 4,750 | 2,850 | Not Rated | 9,000 | Required | -50 to 300 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

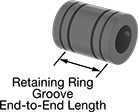

Ball Bearings with Retaining Ring

Retaining Ring, mm | Temp. Range, ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | OD | Thk. | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shielded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 44.6 | 1.12 | 1 | 2,200 | 19,000 | -20 | 230 | Standard | 6203-2Z | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 44.6 | 1.12 | 1 | 2,200 | 12,000 | -40 | 210 | Standard | 6203-2RS | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

One-Way-Locking Ball Bearings

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Max. Torque, ft·lbf | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shielded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,270 | 8,200 | 23 | -40 | 170 | Standard | FZ 6203 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 17 | 1 | 1,270 | 7,300 | 23 | -40 | 170 | Standard | FZ 6203 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

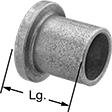

Flanged Sleeve Bearings

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Load Chemical-Resistant 954 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 25 | 50 | 5 | 5,200 lb. @ 30 rpm | 8,750 lb. @ 30 rpm | -350 to 500 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 30 | 50 | 5 | 6,250 lb. @ 30 rpm | 8,750 lb. @ 30 rpm | -350 to 500 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 50 | 5 | 8,350 lb. @ 30 rpm | 8,750 lb. @ 30 rpm | -350 to 500 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 25 | 45 | 2.5 | 6,100 lb. @ 30 rpm | 4,350 lb. @ 30 rpm | -350 to 500 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball Bearings for Food and Beverage

|

Sealed |

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | Inner Ring Type | Food Industry Std. | Bearing Trade No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,800 | 10,000 | -40 | 200 | Standard | FDA Compliant 21 CFR 178.3570 | 6203-2RS | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Graphite-Lubricated Ball Bearings

|

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shielded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 2,200 | 300 | -70 | 660 | Standard | 6203-2Z | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Sleeve Bearings

|

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Color | Temp. Range, ° F | 1-24 | 25-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 25 | 310 lb. @ 30 rpm | Off-White | -10 to 220 | 00000000 | 000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 60 | 750 lb. @ 30 rpm | Off-White | -10 to 220 | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 40 | 30 | 370 lb. @ 30 rpm | Off-White | -10 to 220 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Moisture-Resistant Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 540 lb. @ 30 rpm | White | -20 to 180 | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Chemical-Resistant PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 200 lb. @ 30 rpm | White | -350 to 500 | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load Moisture-Resistant Rulon LR | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 1,850 lb. @ 30 rpm | Maroon | -400 to 550 | 0000000 | 000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Precision Angular Contact Ball Bearings

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Material | Dynamic Combined Load Cap., lbf | Max. Rotation Speed, rpm | Lubrication | Contact Angle | Min. | Max. | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Row | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 7 | Steel | 2,550 | 40,400 | Required | 15° | -40 | 245 | 7203 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Needle-Roller Bearings

Roller Bearings | Shaft Liners | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Radial Load Cap., lb. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Dynamic | Static | Max. Rotation Speed, rpm | Lubrication | For Shaft Surface Smoothness, Ra, μin | Temp. Range, ° F | Features | Each | For Shaft Dia., mm | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Radial Load—Open with Steel Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 20 | 5,100 | 8,100 | 14,000 | Required | 4 | 0 to 245 | Lubrication Groove, Lubrication Hole | 0000000 | 000000 | 25 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Embedded Sleeve Bearings

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 20 | 1,850 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 25 | 2,300 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 30 | 2,750 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 3,700 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 50 | 4,650 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 60 | 5,550 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 40 | 20 | 1,950 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 40 | 25 | 2,450 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 40 | 30 | 2,950 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 40 | 32 | 3,150 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 40 | 40 | 3,950 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 25 | 4,350 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 7,000 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 40 | 32 | 5,600 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sleeve Bearings

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Load 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 40 | 50 | 7,750 lb. @ 60 rpm | -350 to 450 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 40 | 100 | 15,500 lb. @ 60 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 20 | 3,700 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 30 | 5,550 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 7,400 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 50 | 9,300 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 65 | 12,050 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 75 | 13,950 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 100 | 18,600 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 40 | 8,650 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 50 | 10,850 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 75 | 16,250 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 100 | 21,700 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Ball Bearings

Temp. Range, ° F | 316 Stainless Steel Balls | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | ABEC Rating | Bearing Trade No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 65 | 1,000 | -40 | 180 | Not Rated | 6203 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dry-Running Sleeve Bearings for Food and Beverage

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Color | Temp. Range, ° F | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Moisture-Resistant UHMW Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 400 lb. @ 30 rpm | White | -200 to 180 | FDA Compliant 21 CFR 177.1520 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Low-Friction Oil-Embedded Sleeve Bearings

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Base Oil | Lubricant Additive | Temp. Range, ° F | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 30 | 2,750 lb. @ 30 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 40 | 32 | 3,150 lb. @ 30 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 25 | 4,350 lb. @ 30 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 30 | 5,250 lb. @ 30 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 7,000 lb. @ 30 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Low-Friction Oil-Embedded Flanged Sleeve Bearings

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Base Oil | Lubricant Additive | Temp. Range, ° F | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 25 | 45 | 2.5 | 2,700 lb. @ 30 rpm | 1,900 lb. @ 30 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 32 | 45 | 2.5 | 5,600 lb. @ 30 rpm | 2,400 lb. @ 30 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Graphite-Lubricated Sleeve Bearings

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Load 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 25 | 4,050 lb. @ 30 rpm | -350 to 450 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 6,500 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 55 | 8,950 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load Chemical-Resistant 954 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 7,250 lb. @ 30 rpm | -350 to 500 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grooved Sleeve Bearings

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Load 932 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 40 | 100 | 13,550 lb. @ 60 rpm | -350 to 450 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 25 | 4,050 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 6,500 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 50 | 8,100 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 75 | 12,200 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 100 | 16,250 lb. @ 30 rpm | -350 to 450 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Embedded Flanged Sleeve Bearings

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 25 | 45 | 2.5 | 2,700 lb. @ 30 rpm | 1,900 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 32 | 45 | 2.5 | 3,450 lb. @ 30 rpm | 1,900 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 25 | 45 | 2.5 | 4,350 lb. @ 30 rpm | 2,400 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 40 | 32 | 45 | 2.5 | 5,600 lb. @ 30 rpm | 2,400 lb. @ 30 rpm | Synthetic Oil | -15 to 300 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

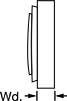

High-Speed Linear Sleeve Bearings

Fixed Alignment

Linear Bearings | Retaining Rings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Shaft Dia., mm | Shaft Clearance, mm | Overall Lg., mm | OD, mm | For Housing ID | With Retaining Ring Grooves | Retaining Ring Groove End-to-End Lg., mm | With End Seals | Dynamic Linear Load Cap. @ Speed | Static Load Cap., lb. | Min. | Max. | For Shaft Material | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic-Lined 6061 Aluminum Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 0.0127 to 0.0381 | 58 | 40 | 40 mm | Yes | 40 | No | 500 lb. @ 100 fpm | 11,250 | -200 | 400 | Stainless Steel, Steel | 0000000 | 000000 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Embedded Sleeve Bearings for Food and Beverage

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 40 | 40 | 3,700 lb. @ 30 rpm | Synthetic Oil | -75 to 300 | FDA Compliant 21 CFR 178.3570 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||