Filter by

Screw Size

ID

Material

Shoulder Diameter

System of Measurement

Application

Shape

DFARS Specialty Metals

Export Control Classification Number (ECCN)

For Use With

REACH

RoHS

Sold As

Magnetic Properties

Minimum Hardness

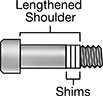

Shims for Lengthening Screw Shoulders

|

When shoulders come up short, use these shims to extend the shoulder length on your screw. Wiggle the shims over the threads and up to the existing shoulder to create the exact shoulder length you need. Use them to create more space for bearings, pulleys, and sprockets, or extend the length of travel along the shoulder.

You can stack multiple shims to achieve the exact shoulder length or space you need.

18-8 Stainless Steel—The choice for wet and outdoor environments, these shims resist rust. However, they’ll corrode or pit when exposed to salt water and chemicals.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these shims won't degrade when exposed to harsh weather, salt water, and most chemicals.

Stress-Resistant Spring Steel—These shims are harder and hold their shape better than carbon steel. Use them for high-stress applications, such as leveling heavy machinery. They're best for dry environments since moisture will cause them to rust.

Thk. | Thk. Tolerance | For Screw Size | ID | ID Tolerance | OD | OD Tolerance | Min. Hardness | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1/4" Diameter Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | No. 10 | 0.171" | 0" to 0.011" | 0.241" | -0.002" to 0.002" | Rockwell B70 | 50 | 90135A431 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.016" | -0.002" to 0.002" | No. 10 | 0.171" | 0" to 0.011" | 0.241" | -0.002" to 0.002" | Rockwell B70 | 50 | 90135A443 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.03" | -0.003" to 0.003" | No. 10 | 0.171" | 0" to 0.011" | 0.241" | -0.002" to 0.002" | Rockwell B70 | 25 | 90135A455 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1/4" Diameter Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | No. 10 | 0.171" | 0" to 0.011" | 0.241" | -0.002" to 0.002" | Rockwell B70 | 10 | 91017A456 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.016" | -0.002" to 0.002" | No. 10 | 0.171" | 0" to 0.011" | 0.241" | -0.002" to 0.002" | Rockwell B70 | 10 | 91017A556 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.03" | -0.003" to 0.003" | No. 10 | 0.171" | 0" to 0.011" | 0.241" | -0.002" to 0.002" | Rockwell B70 | 10 | 91017A656 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stress-Resistant Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1/4" Diameter Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | No. 10 | 0.171" | 0" to 0.011" | 0.248" | -0.002" to 0.002" | Rockwell C40 | 25 | 91140A231 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.00075" to 0.00075" | No. 10 | 0.171" | 0" to 0.011" | 0.248" | -0.002" to 0.002" | Rockwell C40 | 50 | 91140A243 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||