Metric Press-Fit Drill Bushings

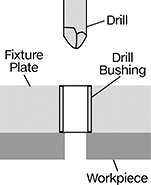

Also known as jig bushings, these metric drill bushings fit inside fixture plate holes to precisely guide drill bits, counterbores, reamers, and other cutting tools. They improve accuracy so that your drilled holes and cuts are consistent from part to part. Known for their versatility, drill bushings are also used as spacers, shims, and machinery bushings. These bushings are made of hardened, ground steel that holds its shape and resists wear, so they last for many cycles without needing to be replaced.

All bushings have a chamfer on the outside that centers the bushing as you place it into the hole. Press into place with a manual or hydraulic press. Since the bushing is sized slightly larger than the hole for an extremely tight fit, it’ll stay put permanently. These are ANSI Type PM bushings—also known as headless bushings—which means you don’t need to counterbore the hole to mount them flush.

They also have an internal chamfer that makes it easy to insert bits, pins, and punches without damaging the bushing or misaligning tools. Bushings with an internal chamfer on both ends allow you to insert tools no matter which end of the bushing is inserted into the jig. However, having an internal chamfer on the bottom of your bushing may cause shavings to get caught and bind as you remove the bit.

DIN 179 bushings meet dimensional and material standards that make sure they're compatible with other parts and tools. Although DIN 179 is no longer an active standard, it's still a common reference point for designers.

Don't see the size you need? Additional sizes are available.

Tolerance | Each | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Lg., mm | Internal Chamfer | For Drill Bit Size | For Drill Bit Size Decimal Equivalent | ID, mm | OD, mm | Lg., mm | Drill Bushing Type | Material | Hardness | Specifications Met | 1-5 | 6-11 | 12-Up | |

6.1 mm ID | |||||||||||||||

| 12 | 10 | One End | 6.1 mm | 0.2402" | 0.013 to 0.028 | 0.012 to 0.023 | -0.25 to 0.25 | PM | Steel | Rockwell C61 | DIN 179 | 00000000 | 000000 | 000000 | 00000 |

| 12 | 10 | Both Ends | 6.1 mm | 0.2402" | 0.013 to 0.028 | 0.012 to 0.023 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | __ | 000000000 | 00000 | 0000 | 0000 |

| 12 | 16 | One End | 6.1 mm | 0.2402" | 0.013 to 0.028 | 0.012 to 0.023 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 000000000 | 00000 | 0000 | 0000 |

| 12 | 16 | Both Ends | 6.1 mm | 0.2402" | 0.013 to 0.028 | 0.012 to 0.023 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | __ | 000000000 | 00000 | 00000 | 0000 |

| 12 | 20 | One End | 6.1 mm | 0.2402" | 0.013 to 0.028 | 0.012 to 0.023 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 000000000 | 00000 | 00000 | 00000 |

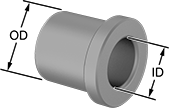

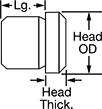

Metric Press-Fit Drill Bushings with Head

Even under extreme drilling pressure, these metric bushings won't press through your jig plate. They’re ANSI Type H bushings, also known as headed bushings. A flanged head acts as a stop, so these bushings won’t move as you push down your drill bit, reamer, or other cutting bit. Use them even in jigs made of thin or soft materials—the head adds support to protect your jig from damage caused by heavy use. Drill bushings ensure accurate, consistent cuts and drilled holes from one part to the next. They’re also used as spacers, shims, and machinery bushings. Made of hardened, ground steel, these bushings hold their shape and resist wear, so they last for many cycles without needing to be replaced.

These bushings meet DIN 172 dimensional standards. This standard is no longer active, but it’s often used as a reference point for making sure parts are compatible with other parts and tools.

To install, fit the bushing into a hole in your jig. In a standard hole, the head will sit above the jig plate; to mount flush, install in a countersunk hole. A chamfered edge on the bottom of the bushing helps center the bushing in the hole. Once it’s centered, press the bushing into the hole with a hydraulic or lever press.

Head | Tolerance | Each | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Lg., mm | For Drill Bit Size | For Drill Bit Size Decimal Equivalent | OD, mm | Thick., mm | ID, mm | OD, mm | Lg., mm | Drill Bushing Type | Material | Hardness | Specifications Met | 1-5 | 6-11 | 12-Up | |

6.1 mm ID | ||||||||||||||||

| 12 | 7 | 6.1 mm | 0.2402" | 15 | 3 | 0.013 to 0.028 | 0.012 to 0.023 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 000000 | 000000 | 00000 |

| 12 | 13 | 6.1 mm | 0.2402" | 15 | 3 | 0.013 to 0.028 | 0.012 to 0.023 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 00000 |

| 12 | 17 | 6.1 mm | 0.2402" | 15 | 3 | 0.013 to 0.028 | 0.012 to 0.023 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 00000 | 00000 | 00000 |