Filter by

System of Measurement

OD

Thread Size

Face Style

Specifications Met

Thread Spacing

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Plain Bearing Type

Spanner Wrench Style

Lubricant

Shaft Type

Shape

Base Oil

Maximum Temperature

Minimum Temperature

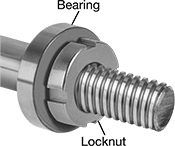

Bearing Locknuts

Ultra-Low-Friction Oil-Embedded Thrust Bearings

|

For Shaft Dia. | OD | Thk. | Dynamic Thrust Load Cap. @ Speed | Base Oil | Lubricant Additive | Temp. Range, ° F | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 3 7/8" | 1/4" | 9,800 lb. @ 30 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 7421K136 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 3 7/8" | 1/4" | 6,600 lb. @ 30 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 7380N171 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Embedded Thrust Bearings

|

For Shaft Dia. | OD | Thk. | Dynamic Thrust Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 3 7/8" | 1/4" | 9,600 lb. @ 30 rpm | Synthetic Oil | -35 to 300 | 5906K591 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wide-Rim Shims

|

Thk. | Thk. Tolerance | ID Tolerance | OD Tolerance | Min. Hardness | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 1/2" ID × 3 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.134" | -0.008" to 0.008" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 1 | 97063A555 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 1/2" ID × 3 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.134" | -0.008" to 0.008" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 1 | 97669A531 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

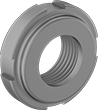

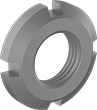

Bearing Nuts

Nuts | Bearing Lock Washers | Sockets | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Size | Spacing | OD | Wd. | Specs. Met | For Lock Washer Specs. Met | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chamfered Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.933"-12 | Extra Fine | 3 7/8" | 19/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 3554N118 | 000000 | 90391A168 | 00000 | 5510N133 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chamfered Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.933"-12 | Extra Fine | 3 7/8" | 19/32" | ANSI/ABMA 8.2 | ANSI/ABMA 8.2 | 4464N27 | 000000 | 90464A270 | 00000 | 5510N133 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||