Filter by

For Use On

System of Measurement

Material

Maximum Bending Angle

DFARS Specialty Metals

Bend Radius

Export Control Classification Number (ECCN)

Roller Material

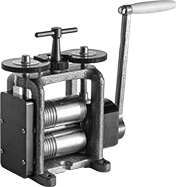

Benchtop Rolling Mills

Manual

For Max. Steel | Roller | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Thk. | Square Wire Size | Half-Round Wire Size | Gear Speed Ratio | Ht. | Wd. | Dp. | Handle Lg. | Dia. | No. of | Material | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 9/16" | 3/16" | 3/64", 5/64", 1/8", 5/32", 3/16", 13/64", 7/32", 15/64", 1/4" | 0.098", 0.118", 0.157" | 4:1 | 14" | 12" | 8" | 12" | 2 1/2" | 2 | Steel | Cast Iron | No | 6 | 3/8" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

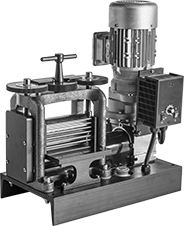

Electric

For Max. Steel | Roller | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Thk. | Gear Speed Ratio | Ht. | Wd. | Dp. | Dia. | No. of | Material | Frame Material | Power, hp | Max. Rotation Speed, rpm | Current, amp | Voltage, V AC | Cord Lg., ft. | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/4" | 3/16" | 100:1 | 19" | 22" | 15" | 2 1/2" | 2 | Steel | Cast Iron | 1/2 | 13 | 1.7 | 120 | 5 | No | 4 | 1/2" | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tube Benders for Soft Metal

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | Bend Radius | Max. Bending Angle | Angle Increments | Material | Mandrel Material | Lg. | Wd. | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Copper, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 4" | 90° | 15°, 30°, 45°, 60°, 90° | Iron | Iron | 10 1/4" | 4 1/4" | 3 | 9/16" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

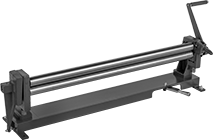

Slip Rollers

Roller | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Bending Wd. | For Max. Steel Thk. | Min. Bending Radius | For Wire Dia. | Ht. | Wd. | Dp. | Material | Dia. | No. of | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1/32" | 1/2" | 1/16", 1/8" | 8" | 17" | 12" | Steel | 1" | 3 | Cast Iron | No | 4 | 3/8" | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1/32" | 1" | 3/16", 1/4", 5/16" | 19" | 38" | 19" | Steel | 2" | 3 | Iron | No | 4 | 3/8" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 1/32" | 1" | 3/16", 1/4", 5/16" | 19" | 51" | 19" | Steel | 2" | 3 | Iron | No | 4 | 3/8" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42" | 1/64" | 1" | 3/16", 1/4", 5/16" | 19" | 57" | 19" | Steel | 2" | 3 | Iron | No | 4 | 3/8" | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

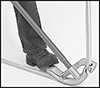

Conduit Benders

|  |

Heads | Steel Handles | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Conduit Trade Size | Cast Iron | |||||||||||

EMT | IMC | Rigid | Bend Radius | Angle Increments | Handle Socket Dia. | Lg. | Ht. | Each | Each | |||

| 1/2 | — | — | 4 1/4" | 10°, 22.5°, 30°, 45°, 60°, 90° | 3/4" | 7 3/4" | 4 3/4" | 000000 | 000000 | 0000000 | 000000 | |

| 3/4 | 1/2 | 1/2 | 5 1/8" | 10°, 22.5°, 30°, 45°, 60°, 90° | 3/4" | 9 1/2" | 6" | 000000 | 00000 | 0000000 | 00000 | |

| 1 | 3/4 | 3/4 | 6 1/2" | 10°, 22.5°, 30°, 45°, 60°, 90° | 1" | 12" | 7 1/2" | 000000 | 000000 | 0000000 | 00000 | |

| 1 1/4 | 1 | 1 | 9 5/8" | 10°, 22.5°, 30°, 45°, 60°, 90° | 1 1/4" | 17" | 9 3/8" | 000000 | 000000 | 0000000 | 00000 | |

Sheet Metal Bead Rollers

Roller | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Throat Dp. | Ht. | Wd. | Dp. | For Max. Steel Thk. | Mount Type | Max. Mounting Surface Thk. | Material | Ctr.-to-Ctr. | Material | Includes | Each | |||

| 7" | 35" | 15 3/8" | 21 1/8" | 1/64" | C-Clamp | 2 3/4" | Steel | 2" | Iron | Rollers for Burring, Crimping, Wiring, 1/8" Turning, and 3/4" Ogee Bending | 0000000 | 000000000 | ||