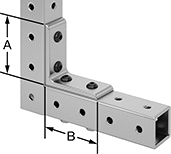

Steel Bolt-Together Framing and Fittings

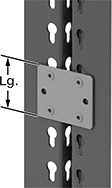

Rails are drilled with consistently spaced holes for multiple mounting options that do not require machining. Use this bolt-together framing to build guards, tables, and racks.

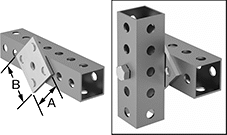

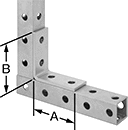

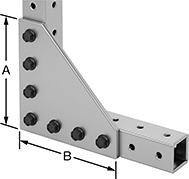

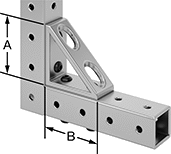

Surface and corner brackets connect rails.

Extended surface brackets have more connection points than standard surface brackets for a stronger joint.

Zinc-plated steel brackets resist corrosion better in wet environments than plain steel brackets.

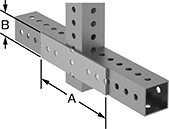

Lg. | Mounting Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bracket Style | For Rail Ht. | (A) | (B) | Thick. | Material | No. of | Ctr.-to-Ctr. | Mounting Fasteners Included | For Screw Size | Each | |

| 90° Angle | 1 1/2", 1 3/4", 2", 2 1/4", 2 1/2" | 3 1/2" | 3 1/2" | 1/8" | Zinc-Plated Steel | 4 | 1" | No | 7/16" | 00000000 | 00000 |

| Flush 90° Angle | 1 1/2", 1 3/4", 2", 2 1/4", 2 1/2" | 4 3/4" | 4 3/4" | 3/16" | Zinc-Plated Steel | 3 | 1" | No | 7/16" | 00000000 | 0000 |

| Flush 90° Angle | 1 5/8", 1 7/8" | 3 1/2" | 3 1/2" | 1/4" | Zinc-Plated Steel | 3 | 1 7/8" | No | 9/16" | 00000000 | 0000 |

| Extended Flush 90° Angle | 1 5/8", 1 7/8" | 5 3/8" | 3 1/2" | 1/4" | Zinc-Plated Steel | 4 | 1 7/8" | No | 9/16" | 00000000 | 0000 |

| Crossover | 1 1/2", 1 3/4", 2", 2 1/4", 2 1/2" | 2 1/4" | 2 1/4" | 3/16" | Zinc-Plated Steel | 1 | 1" | No | 7/16" | 00000000 | 0000 |

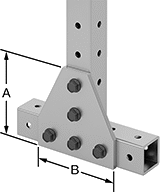

| Flush Tee | 1 1/2", 1 3/4", 2", 2 1/4", 2 1/2" | 3" | 5 1/4" | 3/16" | Zinc-Plated Steel | 2 | 1" | No | 7/16" | 00000000 | 0000 |

| Extended Flush Tee | 1 5/8", 1 7/8" | 5 3/8" | 3 1/2" | 1/4" | Zinc-Plated Steel | 4 | 1 7/8" | No | 9/16" | 00000000 | 0000 |

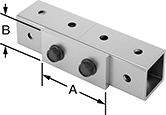

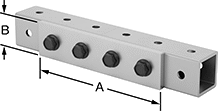

| Straight | 1 5/8", 1 7/8" | 3 1/2" | 1 5/8" | 1/4" | Zinc-Plated Steel | 2 | 1 7/8" | No | 9/16" | 00000000 | 0000 |

| Extended Straight | 1 1/2", 1 3/4", 2", 2 1/4", 2 1/2" | 8" | 2" | 3/16" | Zinc-Plated Steel | 3 | 1" | No | 7/16" | 00000000 | 0000 |

| Extended Straight | 1 5/8", 1 7/8" | 7 1/4" | 1 5/8" | 1/4" | Zinc-Plated Steel | 4 | 1 7/8" | No | 9/16" | 00000000 | 0000 |

| Offset Wraparound | 1 5/8", 1 7/8" | 5 3/8" | 1 7/8" | 1/4" | Zinc-Plated Steel | 5 | 1 7/8" | No | 9/16" | 00000000 | 0000 |

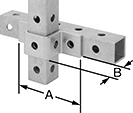

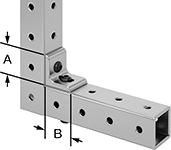

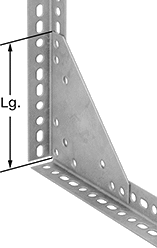

Surface and corner brackets connect rails.

Extended surface brackets have more connection points than standard surface brackets for a stronger joint.

Zinc-plated steel brackets resist corrosion better in wet environments than plain steel brackets.

Galvanized steel brackets resist corrosion better in wet environments than zinc-plated steel brackets.

Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bracket Style | For Rail Ht. | (A) | (B) | Thick. | Mounting Hole Ctr.-to-Ctr. | Mounting Fasteners Included | For Screw Size | Each | |

Zinc-Plated Steel | |||||||||

| Corner | 1 1/2", 1 3/4", 2", 2 1/4", 2 1/2" | 2" | 2" | 3/16" | __ | No | 7/16" | 00000000 | 00000 |

| Corner | 1 5/8", 1 7/8" | 2 1/4" | 1 5/8" | 1/4" | __ | No | 9/16" | 00000000 | 0000 |

| 45° Outside Angle | 1 1/2", 1 3/4", 2", 2 1/4", 2 1/2" | 2 1/8" | 2 1/4" | 3/16" | __ | No | 7/16" | 00000000 | 0000 |

Galvanized Steel | |||||||||

| Extended Corner | 1 5/8", 1 7/8" | 3 7/8" | 3 7/8" | 1/4" | 1 7/8" | No | 9/16" | 00000000 | 00000 |

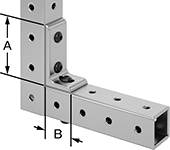

Aluminum Bolt-Together Framing and Fittings

Half the weight of steel, this aluminum framing resists corrosion in wet environments. Rails are drilled with consistently spaced holes for multiple mounting options that do not require machining. Use this bolt-together framing to build guards, tables, and racks.

Add panel hangers to your framing to create machine guards, strip doors, and welding curtains.

Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Rail Ht. | (A) | (B) | Thick. | Material | Mounting Fasteners Included | For Screw Size | Each | |

| 1 1/2" | 1" | 1" | 1/8" | Aluminum | Yes | 5/16" | 0000000 | 00000 |

Install anti-rotation plates where rails meet at a 90° angle to prevent them from twisting due to uneven loads or forces.

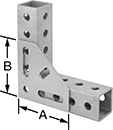

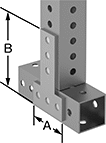

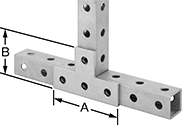

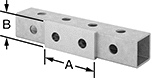

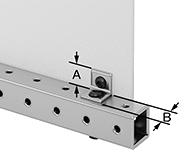

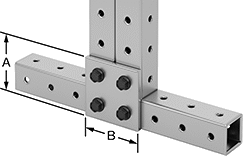

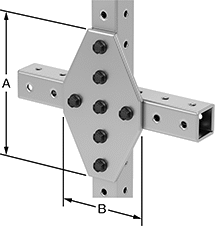

Surface brackets connect rails.

Extended brackets have more connection points than standard brackets for a stronger hold.

Lg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Bracket Style | For Rail Ht. | (A) | (B) | Thick. | Material | Mounting Hole Ctr.-to-End | Mounting Fasteners Included | For Screw Size | Each | |

| Straight | 1 1/2", 1 3/4", 2" | 3" | 1 1/2" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 000000 |

| Extended Straight | 1 1/2", 1 3/4", 2" | 6" | 1 1/2" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

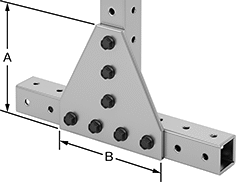

| Tee | 1 1/2", 1 3/4", 2" | 4 1/2" | 4 1/2" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

| Extended Tee | 1 1/2", 1 3/4", 2" | 6" | 6" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

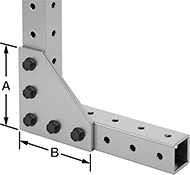

| 90° Angle | 1 1/2", 1 3/4", 2" | 4 1/2" | 4 1/2" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

| Extended 90° Angle | 1 1/2", 1 3/4", 2" | 6" | 6" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

| Square | 1 1/2", 1 3/4", 2" | 3" | 3" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

| Cross | 1 1/2", 1 3/4", 2" | 7 1/2" | 4 1/2" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

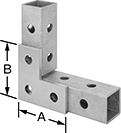

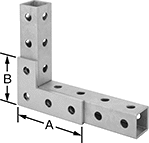

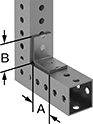

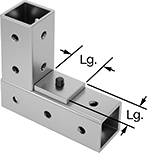

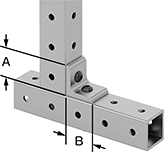

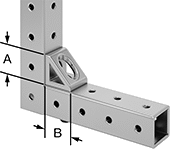

Corner brackets connect rails.

Extended brackets have more connection points than standard brackets for a stronger hold.

Slotted brackets have slotted holes for more adjustability than standard brackets.

Gusset brackets are reinforced to limit sway and add structural stability.

Lg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Bracket Style | For Rail Ht. | (A) | (B) | Thick. | Material | Mounting Hole Ctr.-to-End | Mounting Fasteners Included | For Screw Size | Each | |

| Corner | 1 1/2", 1 3/4", 2" | 1 1/2" | 1 1/2" | 1/4" | Anodized Aluminum | __ | Yes | 5/16" | 0000000 | 00000 |

| Extended Corner | 1 1/2", 1 3/4", 2" | 3" | 3" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

| Slotted Corner | 1 1/2", 1 3/4", 2" | 1 1/2" | 1 1/2" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 0000 |

| Extended Slotted Corner | 1 1/2", 1 3/4", 2" | 3" | 1 1/2" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

| Open Gusset | 1 1/2", 1 3/4", 2" | 1 1/2" | 1 1/2" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

| Extended Open Gusset | 1 1/2", 1 3/4", 2" | 3" | 3" | 1/4" | Anodized Aluminum | 3/4" | Yes | 5/16" | 0000000 | 00000 |

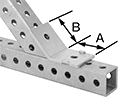

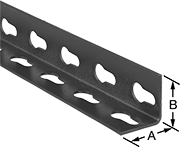

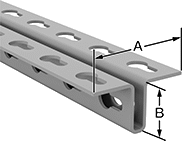

Flat and Angled Bolt-Together Framing and Fittings

Rails are drilled with consistently spaced holes for multiple mounting options that do not require machining. Use this bolt-together framing to build guards, tables, and racks.

Wd. | Mounting Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (A) | (B) | Thick. | Material | Shape | Ctr.-to-Ctr. | For Screw Size | Mounting Fasteners Included | 6 ft. | 8 ft. | |

L-Shaped | ||||||||||

| 1 7/8" | 1 7/8" | 0.0781" | Blue Powder-Coated Steel | Keyhole | 1 1/2" | 1/4", 3/8" | No | 00000000 | ||

| 1 7/8" | 1 7/8" | 0.0781" | Gray Powder-Coated Steel | Keyhole | 1 1/2" | 1/4", 3/8" | No | 00000000 | ||

T-Shaped | ||||||||||

| 2 3/8" | 1 3/16" | 0.0781" | Blue Powder-Coated Steel | Keyhole | 1 1/2" | 1/4", 3/8" | No | 00000000 | ||

| 2 3/8" | 1 3/16" | 0.0781" | Gray Powder-Coated Steel | Keyhole | 1 1/2" | 1/4", 3/8" | No | 00000000 | ||

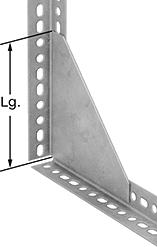

Surface brackets connect rails. These brackets do not have mounting holes already drilled, so you can drill holes where you need them or weld the brackets in place.

Zinc-plated steel brackets are more corrosion resistant in wet environments than powder-coated steel brackets.

Galvanized steel brackets have better corrosion resistance in wet environments than zinc-plated steel brackets, and they can be used outdoors.

Aluminum brackets are half the weight of steel brackets, and they resist corrosion in wet environments.

304 stainless steel brackets are more corrosion resistant than galvanized steel brackets. They also have good chemical resistance.

Surface brackets connect rails.

Zinc-plated steel brackets are more corrosion resistant in wet environments than powder-coated steel brackets.

Galvanized steel brackets have better corrosion resistance in wet environments than zinc-plated steel brackets, and they can be used outdoors.

Aluminum brackets are half the weight of steel brackets, and they resist corrosion in wet environments.

304 stainless steel brackets are more corrosion resistant than galvanized steel brackets. They also have good chemical resistance.