Mitutoyo Small-Bore Dial Gauges

Check for sizing errors in small slots and holes. These bore gauges show deviation from a set diameter measurement on the dial. They’re often used in precision manufacturing to test electronics and small-scale prototypes. The full-ball probe makes 360° contact inside of bores, making it easier to center in tight spots than anvil or spring-loaded contacts. Since it’s symmetrical, the ball is also less likely to tilt and skew measurements than a half-ball probe. The dial head has a plastic cover to protect it from drops and scratches.

Insert the probe into a bore and turn the knob on the handle to expand the contacts. To check size deviations, first set the desired measurement with a ring gauge, bore gauge calibrator, micrometer, or caliper. The dial will display the magnitude of variation from the set measurement. Use a micrometer to measure the distance across the contacts and get the bore diameter. Swap out the anvil to check bores of different diameters.

Dial | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Accuracy | Measuring Increments | Max. Dp. Measured | Probe Type | Measurement per Dial Revolution | Material | Industry Designation | Dia. | Face Color | Number of Anvils | Manufacturer Model Number | Features | Each | |

| 0.037"-0.061" | ±0.00016" | 0.0001" | 0.4" | Full Ball | 0.01" | Stainless Steel | AGD Group 2 | 2 1/4" | White | 5 | 526-176 | Dial Cover | 0000000 | 000000000 |

| 0.059"-0.156" | ±0.00016" | 0.0001" | 0.7" | Full Ball | 0.01" | Stainless Steel | AGD Group 2 | 2 1/4" | White | 9 | 526-166 | Dial Cover | 0000000 | 00000000 |

| 0.146"-0.287" | ±0.00016" | 0.0001" | 1.2" | Full Ball | 0.01" | Stainless Steel | AGD Group 2 | 2 1/4" | White | 7 | 526-156 | Dial Cover | 0000000 | 00000000 |

| 0.3"-0.4" | ±0.00016" | 0.0001" | 2.2" | Full Ball | 0.01" | Stainless Steel | AGD Group 2 | 2 1/4" | White | 6 | 526-122 | Dial Cover | 0000000 | 000000 |

| 0.4"-0.7" | ±0.00016" | 0.0001" | 2.4" | Full Ball | 0.01" | Stainless Steel | AGD Group 2 | 2 1/4" | White | 8 | 526-123 | Dial Cover | 000000000 | 000000 |

Electronic Chamfer Gauges

Whether a chamfered edge is in a screw hole or on the end of a rotary shaft, these gauges find its diameter. Use them to confirm the tolerance of edges after milling, drilling, and reaming. They measure chamfers on the inside or outside diameter of your bore. As you trace the probe of these gauges along an edge, an internal sensor records the distance and angle. The calculated diameter displays on the LCD screen for quick readings. All have SPC data output to transfer information to your computer or data processor—you don’t even need any cables.

Choose a gauge with an angle that is greater than or equal to the chamfer angle you are trying to measure.

For technical drawings and 3-D models, click on a part number.

Measuring Range | Accuracy | Measuring Increments | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Angle Measured | Inch | Metric | Inch | Metric | Inch | Metric | Probe Type | Material | Batteries Included | Each | |

| 15° | 0"-0.39" | 0 mm-10 mm | ±0.002" | ±0.06 mm | 0.0005" | 0.01 mm | Blade | Stainless Steel | Yes | 0000000 | 0000000 |

| 20° | 0"-0.39" | 0 mm-10 mm | ±0.002" | ±0.06 mm | 0.0005" | 0.01 mm | Blade | Stainless Steel | Yes | 0000000 | 000000 |

| 30° | 0"-0.39" | 0 mm-10 mm | ±0.002" | ±0.06 mm | 0.0005" | 0.01 mm | Blade | Stainless Steel | Yes | 0000000 | 000000 |

| 45° | 0"-0.39" | 0 mm-10 mm | ±0.002" | ±0.06 mm | 0.0005" | 0.01 mm | Blade | Stainless Steel | Yes | 0000000 | 000000 |

| 60° | 0"-0.39" | 0 mm-10 mm | ±0.002" | ±0.06 mm | 0.0005" | 0.01 mm | Blade | Stainless Steel | Yes | 0000000 | 000000 |

Starrett Feeler Gauge Sets for Tight Spots

To measure thickness in areas where standard feeler gauges don’t fit, these sets have leaves with narrow ends. They're used to check gaps, alignment, and narrow slots. Sets include leaves in a variety of thicknesses that are riveted together in a fan design that folds up for portability. Each leaf is marked with thickness. Leaf-securing locks hold individual gauge leaves in place.

Stainless steel gauges are less likely to rust than tool steel gauges.

For technical drawings and 3-D models, click on a part number.

Starrett Feeler Gauge Sets for Tight Spots with Calibration Certificate

A certificate of calibration traceable to NIST states that these sets have passed a test for accuracy. They’re used to check small gaps, narrow slots, and alignment. The leaves have a narrow end to measure thickness in areas where standard feeler gauges don’t fit. For example, they can measure gaps when setting engine components such as spark plugs to make sure there’s enough space so friction doesn’t lead to inefficiency.

Sets include leaves in a variety of thicknesses that are riveted together in a fan design that folds up for portability. Each leaf is marked with thickness. Leaf-securing locks hold individual gauge leaves in place.

Stainless steel gauge sets are less likely to rust than tool steel gauge sets.

For technical drawings and 3-D models, click on a part number.

Tapered-Width Feeler Gauge Sets

Check slot widths and hole diameters with the markings on these gauges. Leaves in a variety of sizes are riveted together in a fan design—spread them out for use or fold them in for portability. Each leaf narrows toward the tip to measure a range of sizes. Slide them into a hole until the gauge sits snug and then read the width measurement.

Stainless steel gauges are less likely to rust than steel gauges.

Closed | ||||||

|---|---|---|---|---|---|---|

| No. of Leaves | Wd. | Leaf Lg. | Lg. | Wd. | Each | |

Stainless Steel | ||||||

| 4 | 1 mm to 29 mm (.05 mm increments) | 5 1/4" | 5 1/4" | 1 1/8" | 0000000 | 000000 |

Tapered-Width Feeler Gauges

Confirm slots, holes, and mating surfaces on parts are properly sized. Narrow at one end, these feeler gauges measure a range of sizes. Slide them into a hole until the gauge sits snug and then read the width measurement. All have a range of width markings for quick reference. Made of either stainless steel or plastic, they resist corrosion.

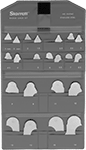

Radius Identifiers

Measure the radius of curves on tools, patterns, and dies. These identifiers are small enough to carry around.

Use style B identifiers as a radius gauge, diameter gauge, and ruler. They check for convex radii. Made of stainless steel, they resist corrosion.

Precision Radius Identifiers

Find precise convex and concave radii of tools, patterns, and dies.

Identifiers with a NIST calibration certificate include a document stating that they have passed a test for accuracy.

| For System of Measurement | No. of Identifiers | For Radius | Material | Container | Container Material | Manufacturer Model No. | Includes | Each | |

Identifiers | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Inch | 25 | 1/64", 1/32", 3/64", 1/16", 5/64", 3/32", 7/64", 1/8", 9/64", 5/32", 11/64", 3/16", 13/64", 7/32", 15/64", 1/4", 17/64", 9/32", 5/16", 11/32", 3/8", 13/32", 7/16", 15/32", 1/2" | Stainless Steel | Pouch | Vinyl | __ | Holder | 0000000 | 000000 |

Mitutoyo Identifiers | |||||||||

| Inch | 8 | 9/16", 5/8", 11/16", 3/4", 13/16", 7/8", 15/16", 1" | Stainless Steel | Pouch | Vinyl | 186-905 | __ | 0000000 | 000000 |

| Inch | 26 | 0.01", 0.015", 0.02", 0.025", 0.03", 0.04", 0.05", 0.06", 0.07", 0.08", 0.09", 0.1", 0.12", 0.14", 0.16", 0.18", 0.2", 0.22", 0.24", 0.26", 0.28", 0.3", 0.35", 0.4", 0.45", 1/2" | Stainless Steel | Pouch | Vinyl | 186-906 | __ | 0000000 | 000000 |

Starrett Identifiers | |||||||||

| Inch | 25 | 1/64", 1/32", 3/64", 1/16", 5/64", 3/32", 7/64", 1/8", 9/64", 5/32", 11/64", 3/16", 13/64", 7/32", 15/64", 1/4", 17/64", 9/32", 5/16", 11/32", 3/8", 13/32", 7/16", 15/32", 1/2" | Stainless Steel | Pouch | Vinyl | S167CHZ | Holder | 000000 | 000000 |

Starrett Identifiers with NIST Certificate | |||||||||

| Inch | 25 | 1/64", 1/32", 3/64", 1/16", 5/64", 3/32", 7/64", 1/8", 9/64", 5/32", 11/64", 3/16", 13/64", 7/32", 15/64", 1/4", 17/64", 9/32", 5/16", 11/32", 3/8", 13/32", 7/16", 15/32", 1/2" | Stainless Steel | Pouch | Vinyl | S167CHZ W/SLC | Holder | 0000000 | 000000 |

| Optional 4" Lg. Steel Gauge Holder | 000000 | Each | 000000 |